Loading ...

Loading ...

Loading ...

Service and maintenance

3-5

3-5

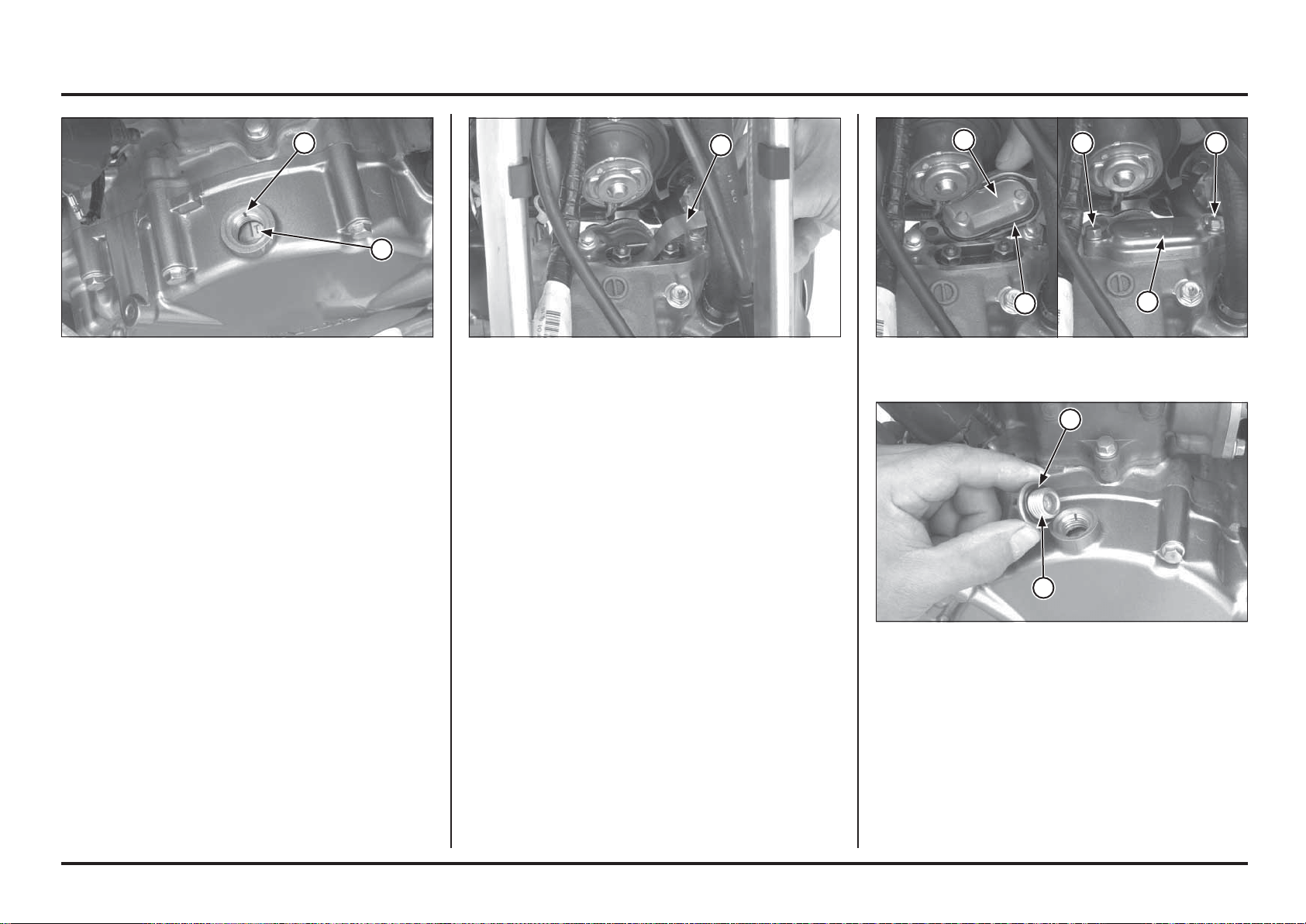

(1) O-RING

(2) TIMING HOLE CAP

Check that the valve adjusting hole cover O-ring is in good

condition, replace if necessary.

Coat the O-rings with clean engine oil and install them in

the valve adjusting hole cover grooves.

Install the valve adjusting hole cover with their “UP” mark

facing up and then install and tighten the bolts securely.

Check the timing hole cap O-ring is in good condition,

replace if necessary.

Install and tighten the timing hole cap.

(1) O-RING

(2) VALVE ADJUSTING HOLE COVER

(3) “UP” MARK (4) BOLTS

Insert a feeler gauge between the rocker arm and

valve stem and measure the intake and exhaust valve

clearances.

Valve clearance:

Intake: 0.12 ± 0.03 mm (0.005 ± 0.001 in)

Exhaust: 0.30 ± 0.03 mm (0.012 ± 0.001 in)

Adjust by loosening the lock nut and turning the adjusting

screw until there is a slight drag on a feeler gauge.

Tools:

Valve adjusting wrench, 10x12 mm (0.39x0.47 in)

(equivalent commercially available)

Tappet wrench, 3 mm (0.118 in) 07908-KE90200

After adjustment, tighten the lock nut while holding the

adjusting screw.

Recheck the valve clearance.

Torque: 14 N•m (1.4 kgf•m, 10.3 lbf•ft)

(1) FEELER GAUGE

Operate the kickstarter pedal and align the “T” mark on

the flywheel with the index mark on the left crankcase

cover.

Make sure the piston is at TDC (Top Dead Center) on the

stroke by moving the rocker arms.

(1) “T” MARK

(2) INDEX MARK

2

1

1

44

3

2

1

2

1

Loading ...

Loading ...

Loading ...