Loading ...

Loading ...

Loading ...

Troubleshooting 29

TROUBLESHOOTING ERROR CODES

Logic 5.0 operators incorporate a self diagnostic feature built into the MAS LED. In addition to indicating when routine maintenance is

due, the MAS LED can be used to troubleshoot problems with the operator.

If the MAS LED on the logic board or 3-button control station is flashing on and off rapidly, the Maintenance Alert System has been

triggered and service is due on the operator. If the MAS LED flashes 2 or more times in a row followed by a pause, an operator error

has occurred. To view the errors, turn the selector dial to DIAG and press the OPEN button. To view the individual error codes (if more

than one exists) press CLOSE. It is possible to have more than one error at a time.

Use the chart below to determine the error.

NOTE: Error codes take priority over normal MAS LED operation. Error codes will repeat on the MAS every 1.5 seconds until cleared.

There may be more than one error present, but only the highest priority will flash. If the highest error is cleared, the next highest will

flash. All errors self-correct when the corrective action is taken. A reset is not needed.

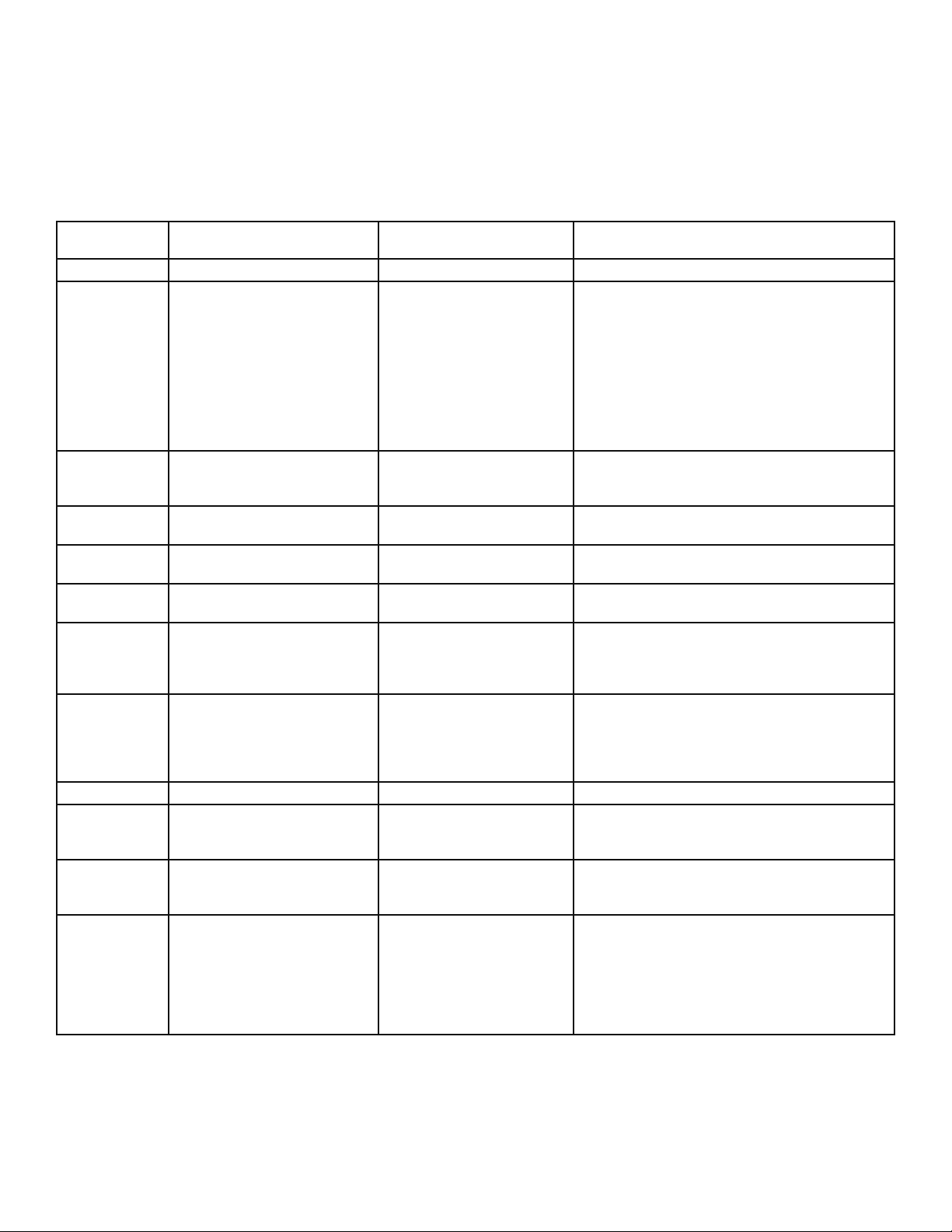

ERROR CODE DESCRIPTION SYMPTOM SOLUTION

1 blink MAS triggered (cycles or months). Normal operation. Reset MAS (page 22).

2 blinks No RPM input during opening or

closing.

The door only responds to

constant pressure commands.

OR

No operator movement for

3-Phase operator.

Clutch is slipping, adjust clutch, or verify RPM sensor

connection or replace RPM sensor.

NOTE: To relearn the RPM sensor, move the door with

a constant pressure command. The door will stop once

relearned and normal operation will resume.

OR

Replace 3-Phase Power Board.

3 blinks (MRT) Maximum Run Time has

timed out.

The door stops before reaching

the desired time.

Check the operator for any faults (e.g., bad limit

switch), program the Max Run Timer OR reset to

factory defaults.

4 blinks Obstruction sensed on closing. Operator will reverse to OPEN

position.

Remove obstruction or realign photoelectric sensor.

5 blinks A button is stuck (longer than 2

minutes).

The control station will not

respond.

The control station must be fixed or replaced before it

will be recognized as an input.

6 blinks Invalid option card plugged into

option card receptacles.

Option card will not function

properly.

Refer to accessories page for list of supported option

card(s).

7 blinks LiftMaster Monitored Entrapment

Protection (LMEP) Device faulted

or removed for greater than

2 minutes.

Normal operation (5 second

constant pressure override

required to close).

Cleared when entrapment protection device is cleared

or connected.

8 blinks Brownout Detected - under voltage. Operator will run as long as

enough power is present.

1. Check AC line for voltage.

2. Check transformer secondary

for low voltage.

Too many accessories may be connected to the

transformer.

9 blinks Power board failure. No operator movement. Replace power board.

10 blinks Operator was not in programming

mode when the motor phase

jumper was changed.

The phase will not change. Enter programming mode and move phase jumper to

change phase.

11 blinks Too much voltage supplied to

operator - over voltage.

Operator will run as long as a

component failure does not

occur.

1. Check AC line for voltage.

2. Voltage to be within +/- 10% of intended voltage.

12 blinks Current sense fault. Motor moves for limited cycles,

then motor no longer moves.

1. Check current sense wiring connection.

2. Cycle operator power after wiring has been

corrected.

OR

1. Replace 3-Phase Power Board.

Loading ...

Loading ...

Loading ...