Loading ...

Loading ...

Loading ...

WIRING

10 Wiring

To reduce the risk of SEVERE INJURY or DEATH:

• ANY maintenance to the operator or in the area near the

operator MUST NOT be performed until disconnecting the

electrical power and locking-out the power. Upon completion of

maintenance the area MUST be cleared and secured, at that

time the operator may be returned to service.

• Disconnect power at the fuse box BEFORE proceeding.

Operator MUST be properly grounded and connected in

accordance with national and local electrical codes. The

operator should be on a separate fused line of adequate

capacity.

• ALL electrical connections MUST be made by a qualified

individual.

• DO NOT install ANY wiring or attempt to run the operator

without consulting the wiring diagram.

• ALL power wiring should be on a dedicated circuit and well

protected. The location of the power disconnect should be

visible and clearly labeled.

• ALL power and control wiring MUST be run in separate

conduit.

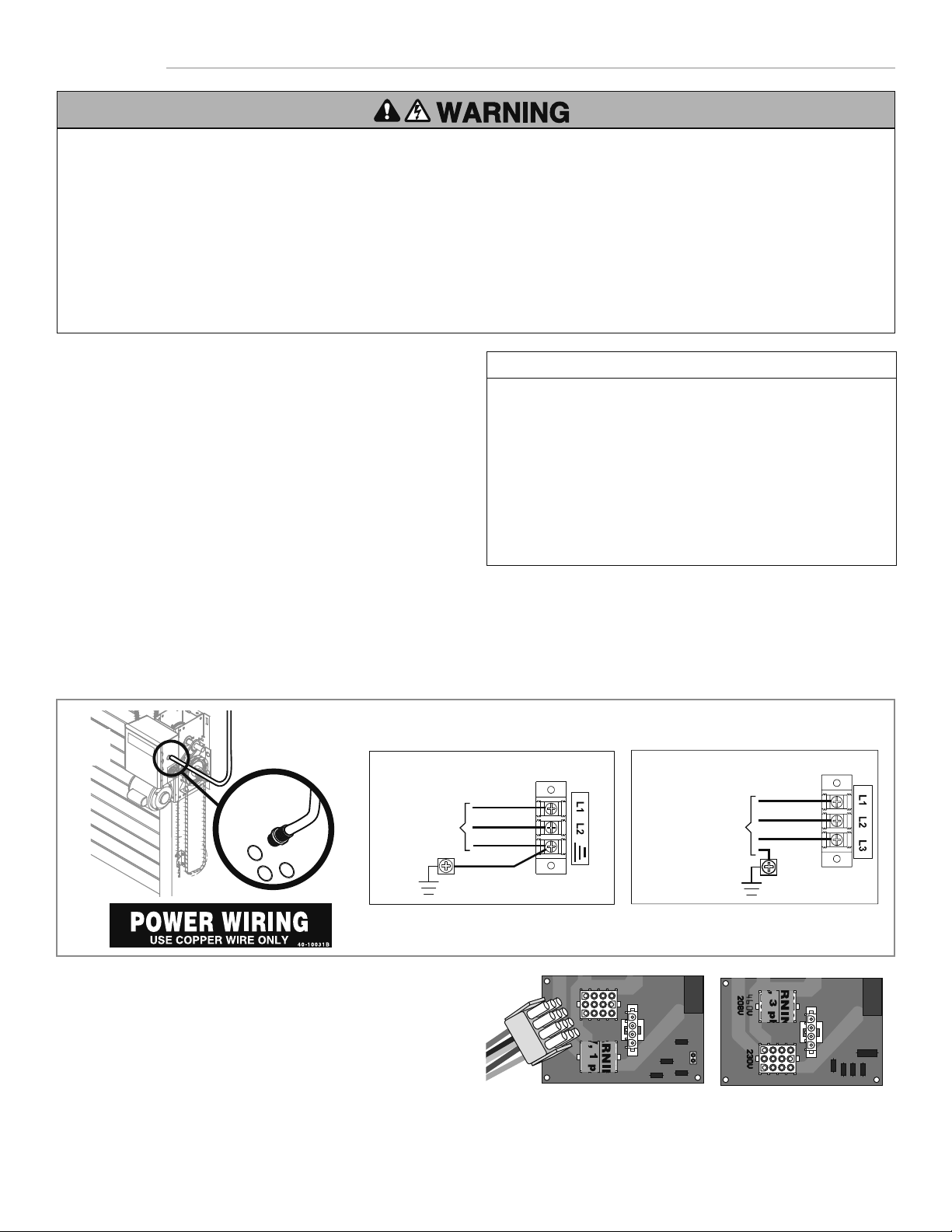

Three Phase Power WiringSingle Phase Power Wiring

Line Power

115/230 Vac

Single Phase

Hot

Neutral

Ground

Phase 1

Phase 2

Phase 3

2

1

3

Line Power

208/230/460/575 Vac

Three Phase

POWER AND GROUND

Power and control wiring must be run in separate conduit in

accordance with national and local electrical codes. Must use

14 AWG or heavier wire for power wiring. Use conduit knockouts

for wiring as indicated on the electrical box labels.

Remove the operator cover.

Attach power and ground wires to appropriate terminals.

IMPORTANT NOTE: This operator must be properly

grounded. Failure to properly ground the operator could

result in electric shock and serious injury.

NOTE: In some installations, such as a through-wall-installation,

the rotation of the motor and logic board may have to be changed.

1. Locate the MOTOR DIRECTION jumper on the logic board.

Remove jumper and relocate from STD to REV.

2. Relocate the sensing limit switch (SLS) to the opposite side.

3. Remove CLOSE/OPEN decal and reattach appropriately.

1

3

2

Run power wires to electrical box according to national and

local electrical codes.

ON THREE PHASE MACHINES ONLY: Incorrect phasing of

the power supply will cause the motor to rotate in the wrong

direction. To change motor rotation, exchange incoming

power leads L1 and L2.

DISTANCE GAUGE

50 feet (15.2 m) 14 AWG

100 feet (30.5 m) 12 AWG

200 feet (61 m) 8 AWG*

350 feet (106.7 m) 6 AWG*

500 feet (152.4 m) 4 AWG*

1000 feet (304.8 m) 2 AWG*

POWER WIRING CHART

*

Maximum wire gauge that can be connected to the operator’s

terminal is 12 AWG. When a larger wire gauge is required, the wire

must be gauged down to 12 AWG. USE COPPER WIRE ONLY.

VOLTAGE SELECTION

Locate motor harness inside of the electrical box.

For all operators except for 575V 3 Phase operators, follow the

steps below. The motor harness is connected to the power board

at the factory on all 575V 3 Phase operators.

1

2

On the POWER BOARD find the appropriate receptacle

matching the incoming line voltage. Remove the voltage label

and apply to the inside of the electrical box for future

reference. Insert the motor harness fully until locked in place.

115V 230V

Motor

Harness

SINGLE PHASE POWER BOARD

3 PHASE POWER BOARD

Fusing on the 3-Phase Power Board is not field-replaceable. An

Open Fuse indicates that the 3-Phase Power Board is damaged

and must be replaced. Failure to replace the complete 3-Phase

Power Board may result in additional damage to the Operator.

Loading ...

Loading ...

Loading ...