Loading ...

Loading ...

Loading ...

28 Servicing Your Honda

General Competition Maintenance

Gaskets

Always use new gaskets when reassembling components.

Cylinder Removal

Put a little grease on the cylinder mounting dowels to

prevent corrosion from dissimilar metals. The tolerances are

extremely tight, so it’s important to keep these dowels

absolutely clean (pages 76, 79).

Engine Mounting Bolts and Nuts

Make sure the engine mounting bolts and nuts are tightened

to the proper torque specification. For added peace of mind,

remove the nuts, clean the threads, and apply Pro Honda

Hondalock or an equivalent before torquing the nuts.

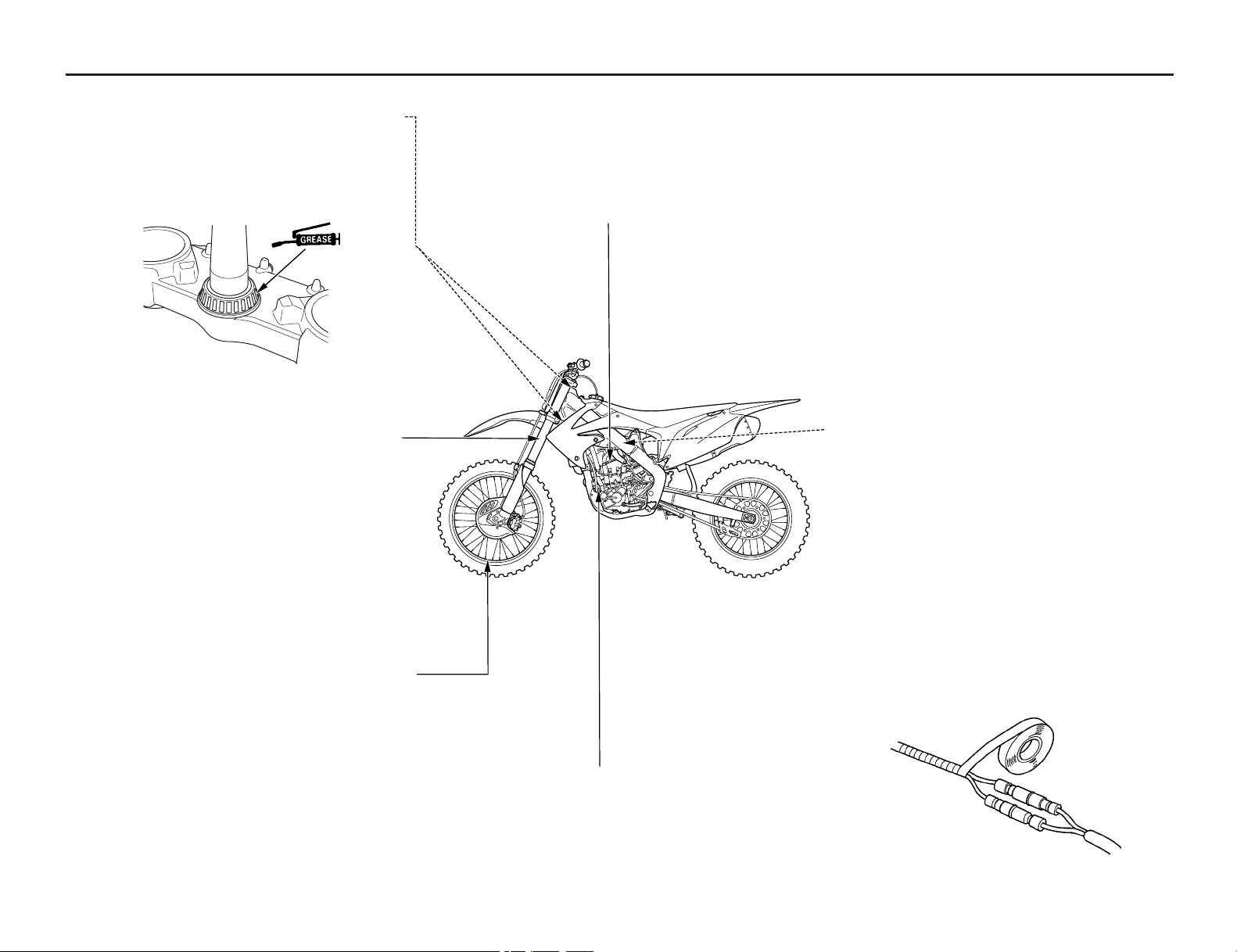

Electrical Connectors

Clean electrical connectors and wrap them with electrical

tape to reduce the possibility of unwanted disconnections,

water shorts or corrosion. For additional corrosion

protection, apply Pro Honda Dielectric Grease to allthe

electrical connections.

Steering Head Bearings

Periodically clean, inspect and regrease the steering head

bearings — especially if wet, muddy or extremely dusty

courses are encountered often.

Use urea based multi-purpose grease designed for high

temperature, high pressure performance (example:

EXCELITE EP2 manufactured by KYODO YUSHI, Japan

or Shell Stamina EP2 or equivalent).

Fork Oil/Performance

Disassemble, clean and inspect the front fork and replace oil

regularly. Contamination due to the tiny metal particles

produced from the normal action of the fork, as well as

normal oil breakdown, will deteriorate the performance of

the suspension. Refer to the Honda Service Manual. Use

only HP Fork Oil, SS-19 or equivalent which contains

special additives to assure maximum performance of your

CRF’s front suspension.

Frame

Because your CRF is a high-performance machine, the frame

should not be overlooked as part of your overall competition

maintenance program. Periodically inspect the frame

closely for possible cracking or other damage. It makes

good racing sense.

Spokes

Check spoke tension frequently between the first few rides.

As the spokes, spoke nuts and rim contact points seat-in, the

spokes may need to be retightened. Once past this initial

seating-in period, the spokes should hold their tension. Still,

be sure your race maintenance program includes checking

spoke tension and overall wheel condition on a regular basis

(page 94).

Nuts, Bolts, Etc

Application of a thread locking agent to essential fasteners

offers added assurance and security. Remove the nuts, clean

the threads of both the nuts and bolts, apply Pro Honda

Hondalock or an equivalent and tighten to the specified

torque.

Fuel Line

Refer to Fuel System on page 40.

Check the fuel line for deterioration, damage, or leakage.

Replace the fuel line every year.

Loading ...

Loading ...

Loading ...