Loading ...

Loading ...

Loading ...

120 Adjustments for Competition

Front Suspension Adjustments

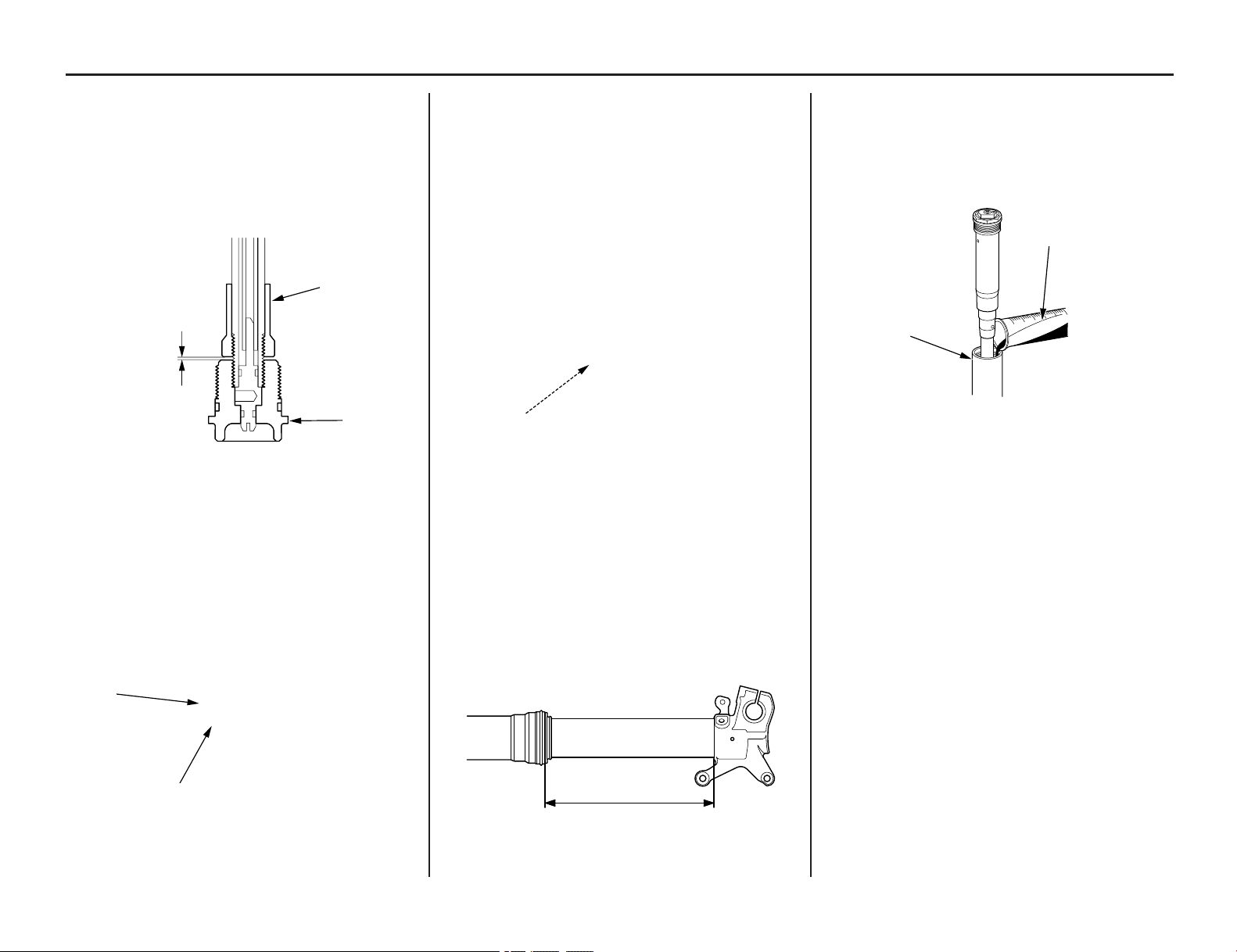

9. Measure the length of the fork center bolt lock

nut (2) and fork center bolt (12) clearance.

Standard

: 0.06 – 0.08 in (1.5 – 2.0 mm)

If the clearance is out of specification, check the

fork center bolt lock nut and fork center bolt

installation.

(2) fork center bolt lock nut (12) fork center bolt

10. Tighten the fork center bolt lock nut (2) to the

fork center bolt (12) closely by hand. Tighten

the fork center bolt lock nut to the specified

torque:

16 Ibf·ft (22 N·m, 2.2 kgf·m)

(2) fork center bolt lock nut

(12) fork center bolt

11. Remove the piston base or mechanic's stopper

tool while pushing the fork damper.

Apply locking agent to the fork center bolt

threads.

Install the fork center bolt (12) to the axle

holder and tighten it to the specified torque:

51 Ibf·ft (69 N·m, 7.0 kgf·m)

(12) fork center bolt

12. Measure the length between the axle holder

and outer tube.

Standard:

12.5 ± 0.1 in (316.5 ± 2 mm)

13. Compare the length (13) at assembly and at

disassembly. They should be the same length.

(13) length

(2)

(12)

0.06 – 0.08 in

(1.5 – 2.0 mm)

(2)

(12)

(12)

(13)

If the length at assembly is longer than at

disassembly, check the fork center bolt and fork

center bolt lock nut installation.

(1) fork assembly (14) fork oil

(1)

(14)

14. Remove the fork damper from the fork.

15. Pour the recommended fork oil (14) into the

fork assembly (1).

Recommended Oil:

HP Fork Oil, SS-19

Loading ...

Loading ...

Loading ...