Loading ...

Loading ...

Loading ...

unpacking and assembly

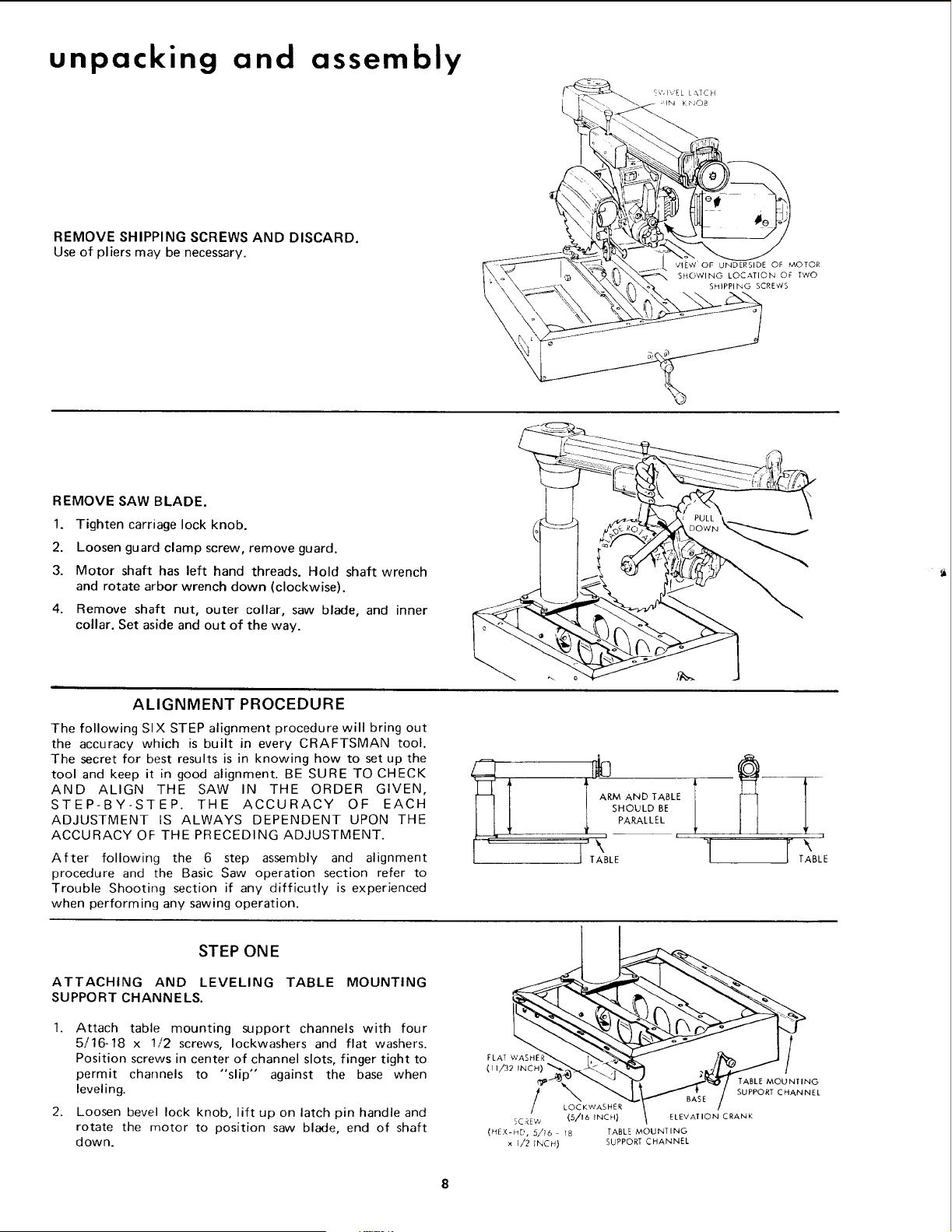

REMOVE SHIPPING SCREWS AND DISCARD.

Use of pliers may be necessary.

E¢, Iv'E L LATCH

;IN KPlO_

__ VIE_V OF UNDERSIDE OF MOTOR

%; Two

_\\\_ SH_ PPliNG SCREWS

REMOVE SAW BLADE.

1. Tighten carriage lock knob.

2. Loosen guard clamp screw, remove guard.

3. Motor shaft has left hand threads. Hold shaft wrench

and rotate arbor wrench down (clockwise).

4. Remove shaft nut, outer collar, saw blade, and inner

collar. Set aside and out of the way.

ALIGNMENT PROCEDURE

The following SIX STEP alignment procedure will bring out

the accuracy which is built in every CRAFTSMAN tool.

The secret for best results is in knowing how to set up the

tool and keep it in good alignment. BE SURE TO CHECK

AND ALIGN THE SAW IN THE ORDER GIVEN,

STEP-BY-STEP. THE ACCURACY OF EACH

ADJUSTMENT IS ALWAYS DEPENDENT UPON THE

ACCURACY OF THE PRECEDING ADJUSTMENT.

After following the 6 step assembly and alignment

procedure and the Basic Saw operation section refer to

Trouble Shooting section if any difficutly is experienced

when performing any sawing operation.

i

1'TA\LE

i

TABLE

STEP ONE

ATTACHING AND LEVELING TABLE MOUNTING

SUPPORT CHANNELS.

2.

Attach table mounting support channels with four

5/16-18 x 1/2 screws, Iockwashers and flat washers.

Position screws in center of channel slots, finger tight to

permit channels to "slip" against the base when

leveling.

Loosen bevel lock knob, lift up on latch pin handle and

rotate the motor to position saw blade, end of shaft

down.

TABLE MOUNTING

SUPPORT CHANNEL

LOCKWASHER

;CREW (5/16 INCH} ELEVATION CRANK

(HEX-HD, 5,716 t8 TABLE MOUNTING

x !/2 INCH) SUPPORT CHANNEL

Loading ...

Loading ...

Loading ...