Loading ...

Loading ...

Loading ...

trouble-shooting

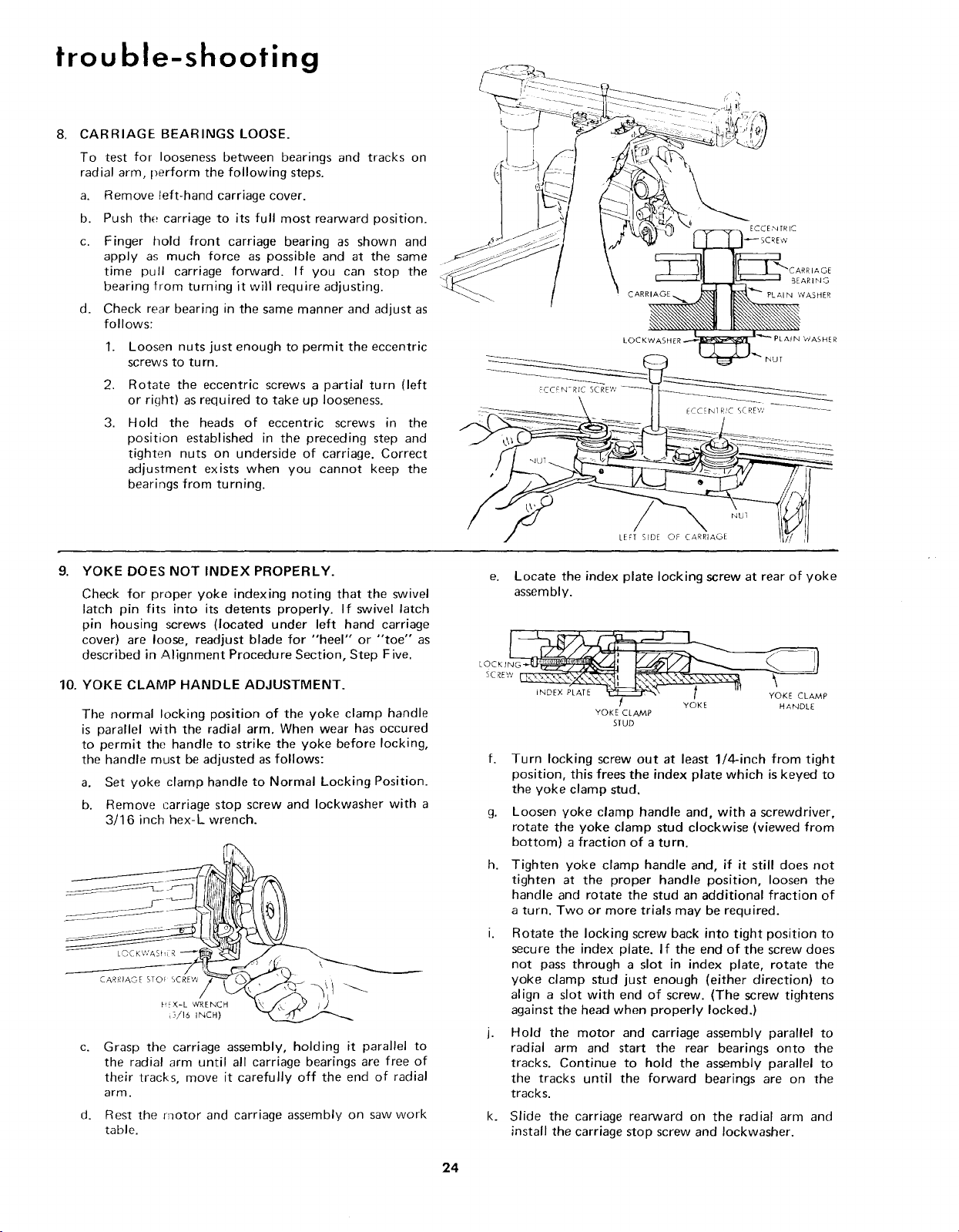

8. CARRIAGE BEARINGS LOOSE.

To test for looseness between hearings and tracks on

radial arm, perform the following steps.

a. Remove left-hand carriage cover.

b. Push the carriage to its full most rearward position.

c. Finger hold front carriage bearing as shown and

apply as much force as possible and at the same

time pull carriage forward. If you can stop the

hearing from turning it will require adjusting.

d. Check rear bearing in the same manner and adjust as

follows:

1. Loosen nuts just enough to permit the eccentric

screws to turn.

2.

3.

Rotate the eccentric screws a partial turn (left

or right) as required to take up looseness.

Hold the heads of eccentric screws in the

position established in the preceding step and

tighten nuts on underside of carriage. Correct

adjustment exists when you cannot keep the

bearings from turning.

ECCENFRIC

5EARINS

PLAIN WASHER

LOCKW_ \SHER

9. YOKE DOES NOT INDEX PROPERLY.

Check for proper yoke indexing noting that the swivel

latch pin fits into its detents properly. If swivel latch

pin housing screws (located under left hand carriage

cover) are loose, readjust blade for "heel" or "toe" as

described in Alignment Procedure Section, Step Five.

10. YOKE CLAMP HANDLE ADJUSTMENT.

The normal locking position of the yoke clamp handle

is parallel with the radial arm. When wear has occured

to permit the handle to strike the yoke before locking,

the handle must be adjusted as follows:

NUI

LEFT SFDE OF CARRIAGE

a, Set yoke clamp handle to Normal Locking Position.

b. Remove carriage stop screw and Iockwasher with a

3/16 inch hex-L wrench.

H.L X-L WRENCH

_5/!6 INCH)

d.

Grasp the carriage assembly, holding it parallel to

the radial arm until all carriage bearings are free of

their tracks, move it carefully off the end of radial

arm.

Rest the motor and carriage assembly on saw work

table.

e. Locate the index plate locking screw at rear of yoke

assembly.

scRE'._.' L

] YOKE HANDL[

YOKE CLAMP

STUD

f. Turn locking screw out at least 1/4-inch from tight

position, this frees the index plate which is keyed to

the yoke clamp stud.

g. Loosen yoke clamp handle and, with a screwdriver,

rotate the yoke clamp stud clockwise (viewed from

bottom) a fraction of a turn.

h. Tighten yoke clamp handle and, if it still does not

tighten at the proper handle position, loosen the

handle and rotate the stud an additional fraction of

a turn. Two or more trials may he required.

i. Rotate the locking screw back into tight position to

secure the index plate. If the end of the screw does

not pass through a slot in index plate, rotate the

yoke clamp stud just enough (either direction) to

align a slot with end of screw. (The screw tightens

against the head when properly locked.)

j. Hold the motor and carriage assembly parallel to

radial arm and start the rear bearings onto the

tracks. Continue to hold the assembly parallel to

the tracks until the forward hearings are on the

tracks.

k.

Slide the carriage rearward on the radial arm and

install the carriage stop screw and Iockwasher.

24

Loading ...

Loading ...

Loading ...