Loading ...

Loading ...

Loading ...

to an overly long supply circuit. Always check the

connections, the load and the supply circuit, whenever

the motor fails to perform satisfactorily. Check wire

sizes and lengths with the table following.

WIRE SIZES

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent

over-heating and motor burn-out, use the table below to

determine the minimum wire size (A.W.G.) extension cord.

Use only 3 wire extension cords which have 3 prong

grounding type plugs and 3-pole receptacles which accept

the tools plug.

Length of the

Conductor

Up to 100 feet

100 feet to 200 feet

200 feet to 400 feet

Wire Size Required

(American Wire Gauge Number)

120 Volt Line

No. 12

No. 8

No. 6

NOTE: For circuits of greater length, the wire size must be

increased proportionately in order to deliver ample voltage

to the saw motor.

trouble-shooting

WARNING: REMOVE POWER CORD FROM POWER

SOURCE BEFORE TROUBLE SHOOTING.

Even' though the finest materials and precision

workmanship have been incorporated into your Craftsman

saw, it is reasonable to expect some wear after long periods

of use. Sooner or later, the metal to metal parts must wear

and will need take-up. Every metal to metal part on your

Craftsman saw can be taken up. In this way, the machine

can always be kept accurate and just as important, rigid.

The usual operating "troubles" are listed in the following

paragraphs with the necessary corrections listed.

LOOSENESS OF COLUMN TUBE IN COLUMN

SUPPORT -- ELEVATION CRANK OPERATES

ROUGHLY OR CHATTERS WHEN ROTATED.

Refer to Step two in Alignment Procedure Section.

Check for looseness (movement) of column tube in

column support.

2.

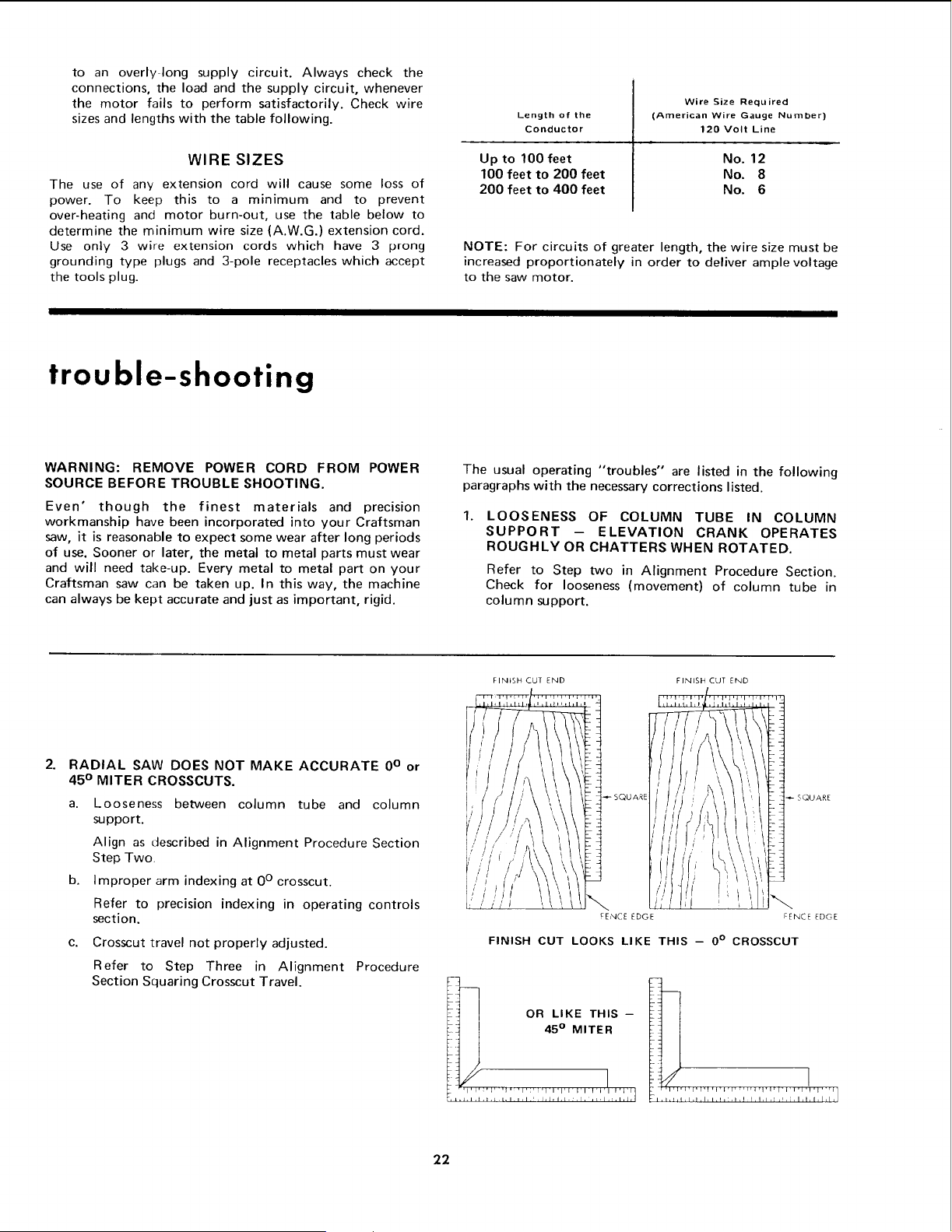

RADIAL SAW DOES NOT MAKE ACCURATE 0° or

45 ° MITER CROSSCUTS.

a. Looseness between column tube and column

support.

Align as described in Alignment Procedure Section

Step Two

b. Improper arm indexing at 0° crosscut.

Refer to precision indexing in operating controls

section.

c. Crosscut travel not properly adjusted.

Refer to Step Three in Alignment Procedure

Section Squaring Crosscut Travel.

FINISH CUT END

_,FFL],I,,,,,,,T_-__

__' _ SQUARE

/ / / / I

FE,MCE EDGE

FINISH CUT END

IiI _ _ SQUARE

FENCE EDGE

FINISH CUT LOOKS LIKE THIS -- 0 ° CROSSCUT

OR LIKE THIS --

22

Loading ...

Loading ...

Loading ...