Loading ...

Loading ...

Loading ...

3. SAW CUTS AT ANGLE - NOT 90 ° TO TABLE TOP.

a. Table support channels not properly leveled.

Refer to Step One under Alignment Procedure

Section.

b. Blade not square to work table top.

Refer to Step four in Alignment Procedure Section.

4. BLADE ANGLE (BEVEL) CUTS NOT ACCURATE.

a. Corrective action is the same as paragraph 3a and b

above.

d. Carriage Bearings Loose

Refer to Step four in Alignment Procedure Section

]HOU'LD BE 90 °

ANGLE

SQUARE

BOARD

/

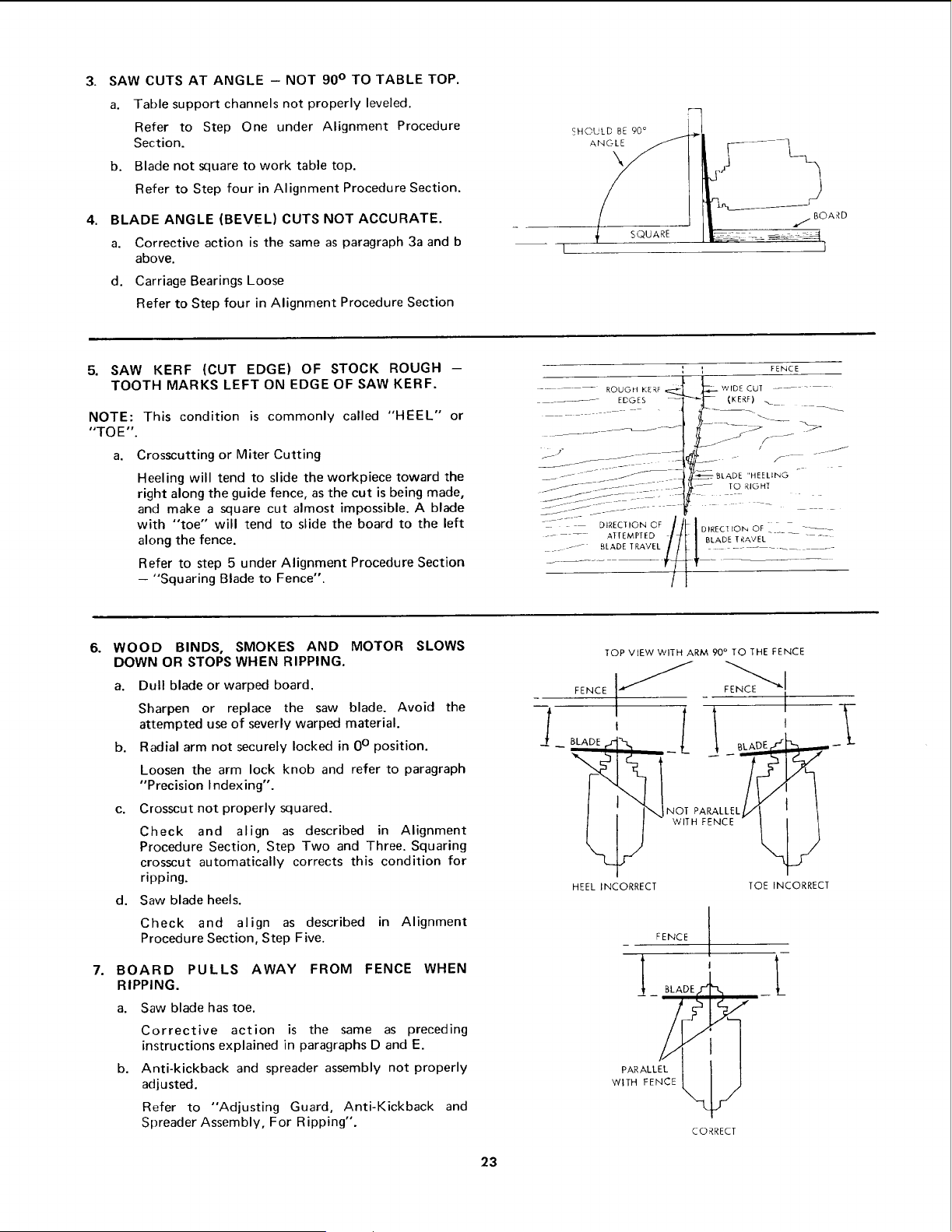

5. SAW KERF (CUT EDGE) OF STOCK ROUGH -

TOOTH MARKS LEFT ON EDGE OF SAW KERF.

NOTE: This condition is commonly called "HEEL" or

"TO E".

a. Crosscutting or Miter Cutting

Heeling will tend to slide the workpiece toward the

right along the guide fence, as the cut is being made,

and make a square cut almost impossible. A blade

with "toe" will tend to slide the board to the left

along the fence.

Refer to step 5 under Alignment Procedure Section

- "Squaring Blade to Fence".

6.

7.

WOOD BINDS, SMOKES AND MOTOR SLOWS

DOWN OR STOPS WHEN RIPPING.

a. Dull blade or warped board.

Sharpen or replace the saw blade. Avoid the

attempted use of severly warped material.

b. Radial arm not securely locked in 0° position.

Loosen the arm lock knob and refer to paragraph

"Precision Indexing".

c. Crosscut not properly squared.

Check and align as described in Alignment

Procedure Section, Step Two and Three. Squaring

crosscut automatically corrects this condition for

ripping.

d. Saw blade heels.

Check and align as described in Alignment

Procedure Section, Step Five.

BOARD PULLS AWAY FROM FENCE WHEN

RIPPING.

a. Saw blade has toe.

Corrective action is the same as preceding

instructions explained in paragraphs D and E.

b. Anti-kickback and spreader assembly not properly

adjusted.

Refer to "Adjusting Guard, Anti-Kickback and

Spreader Assembly, For Ripping".

TOP VIEW WITH ARM 90 ° TO THE FENCE

!

HEEL INCORRECT TOE INCORRECT

FENCE I

PARALLEL

WITH FENCE

CORRECT

23

Loading ...

Loading ...

Loading ...