Loading ...

Loading ...

Loading ...

electrical connections

1.

POWER SUPPLY

Motor Specifications

The A-C motor used in this saw is a capacitor-start,

non-reversible type having the following specifications:

Voltage ............................ 120

Amperes ............................ 12.5

Hertz (cycles) ............................ 60

Phase ................................ Single

RPM ................................. 3450

Rotation as viewed

from saw blade end ................. Clockwise

CAUTION: YOUR SAW IS WIRED FOR 120V

OPERATION. CONNECT TO A 120V, 15-AMP.

BRANCH CIRCUIT AND USE A 15-AMP.,

TIME-DELAY FUSE OR CIRCUIT BREAKER.

WARNING: DO NOT PERMIT FINGERS TO TOUCH

THE TERMINALS OF PLUGS WHEN INSTALLING

OR REMOVING THE PLUG TO OR FROM THE

OUTLET.

WARNING: IF NOT PROPERLY GROUNDED THIS

POWER TOOL CAN INCUR THE POTENTIAL

HAZARD OF ELECTRICAL SHOCK,

PARTICULARLY WHEN USED IN DAMP

LOCATIONS, IN PROXIMITY TO PLUMBING, OR

OUT OF DOORS. IF AN ELECTRICAL SHOCK

OCCURS THERE IS THE POTENTIAL OF A

SECONDARY HAZARD SUCH AS YOUR HANDS

CONTACTING THE SAW BLADE.

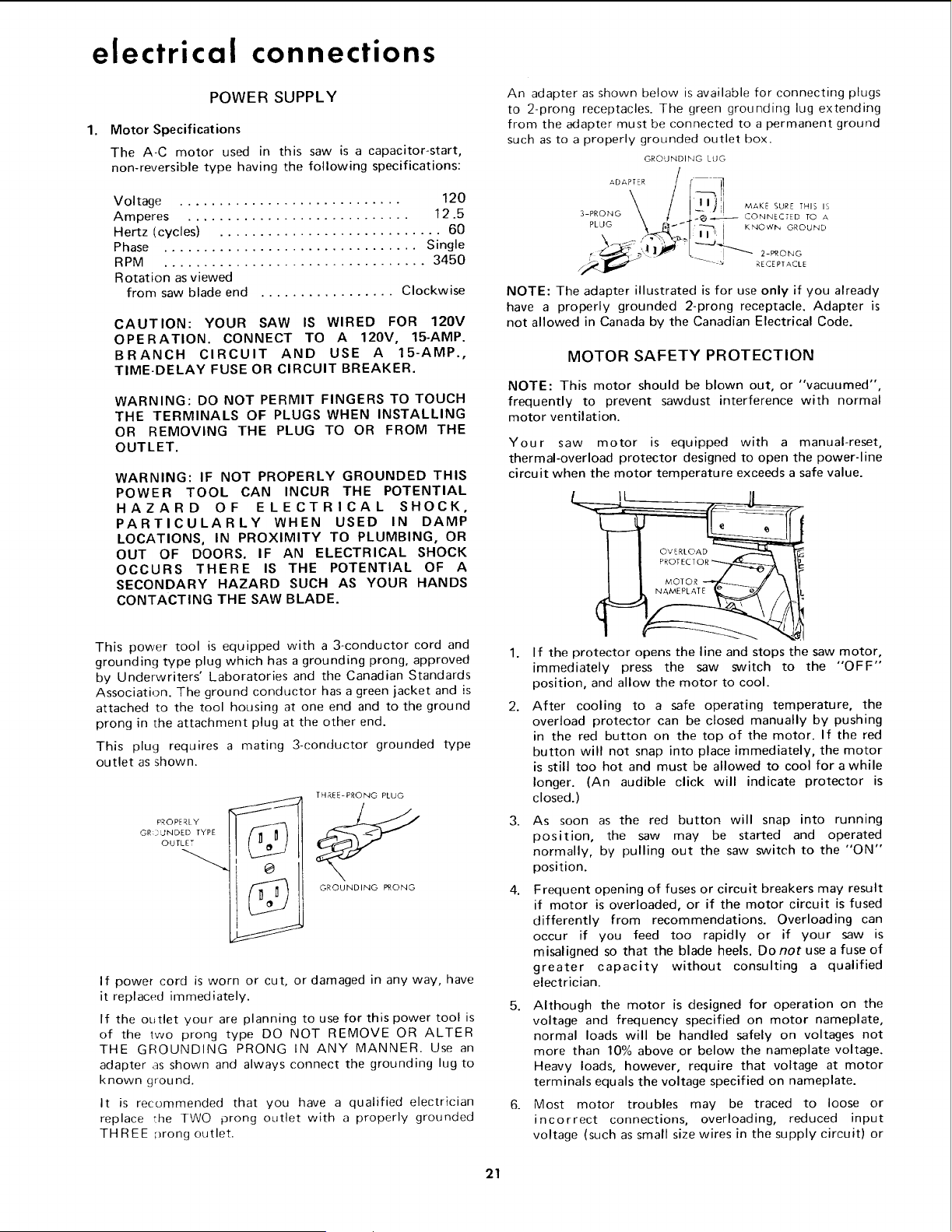

This power tool is equipped with a 3-conductor cord and

grounding type plug which has a grounding prong, approved

by Underwriters' Laboratories and the Canadian Standards

Association. The ground conductor has a green jacket and is

attached to the tool housing at one end and to the ground

prong in the attachment plug at the other end.

This plug requires a mating 3-conductor grounded type

outlet as shown.

PROPERLY

OR:JUNDED TYPE

OUTLE T

THREE-PRONG PLUG

GROUNDING PRONG

If power cord is worn or cut, or damaged in any way, have

it replaced immediately.

If the outlet your are planning to use for this power tool is

of the two prong type DO NOT REMOVE OR ALTER

THE GROUNDING PRONG IN ANY MANNER. Use an

adapter as shown and always connect the grounding lug to

known ground.

It is recommended that you have a qualified electrician

replace the TWO prong outlet with a properly grounded

THREE i)rong outlet.

An adapter as shown below is available for connecting plugs

to 2-prong receptacles. The green grounding lug extending

from the adapter must be connected to a permanent ground

such as to a properly grounded outlet box.

GROUNDING LUG

\ t/ _'1 MAKE_ORE,H,_,_

S-PRONG \ I [_--@ " ' CONNECTED TO A

PLUG '_ I",_I_] ' _ KNO;'VI'w GROUND

f_ _--_ RECEPTACLE

NOTE: The adapter illustrated is for use only if you already

have a properly grounded 2-prong receptacle. Adapter is

not allowed in Canada by the Canadian Electrical Code.

MOTOR SAFETY PROTECTION

NOTE: This motor should be blown out, or "vacuumed",

frequently to prevent sawdust interference with normal

motor ventilation.

Your saw motor is equipped with a manual-reset,

thermal-overload protector designed to open the power-line

circuit when the motor temperature exceeds a safe value.

1.

2.

3.

4.

5.

6.

If the protector opens the line and stops the saw motor,

immediately press the saw switch to the "'OFF"

position, and allow the motor to cool.

After cooling to a safe operating temperature, the

overload protector can be closed manually by pushing

in the red button on the top of the motor. If the red

button will not snap into place immediately, the motor

is still too hot and must be allowed to cool for a while

longer. (An audible click will indicate protector is

closed.)

As soon as the red button will snap into running

position, the saw may be started and operated

normally, by pulling out the saw switch to the "ON"

position.

Frequent opening of fuses or circuit breakers may result

if motor is overloaded, or if the motor circuit is fused

differently from recommendations. Overloading can

occur if you feed too rapidly or if your saw is

misaligned so that the blade heels. Donot use a fuse of

greater capacity without consulting a qualified

electrician.

Although the motor is designed for operation on the

voltage and frequency specified on motor nameplate,

normal loads will be handled safely on voltages not

more than 10% above or below the nameplate voltage.

Heavy loads, however, require that voltage at motor

terminals equals the voltage specified on nameplate.

Most motor troubles may be traced to loose or

incorrect connections, overloading, reduced input

voltage (such as small size wires in the supply circuit) or

21

Loading ...

Loading ...

Loading ...