Loading ...

Loading ...

Loading ...

Exhsus_ System Msin_enanc÷

The dryer inte:rior and the complete exh_mst system

should _ inst_ctcd atier one year of use _mdcleaned if

necesvlry. Inst_ct _mdclean exhaust duct eve:u one m

two years as :required thercali:er.The weather h(×)d

should _ checked frequently to make sure the dampers

move :freely, they are not pushed in and that nothing lms

_en set _gainst them This maintenance work should be

done by"a qualified service persxm

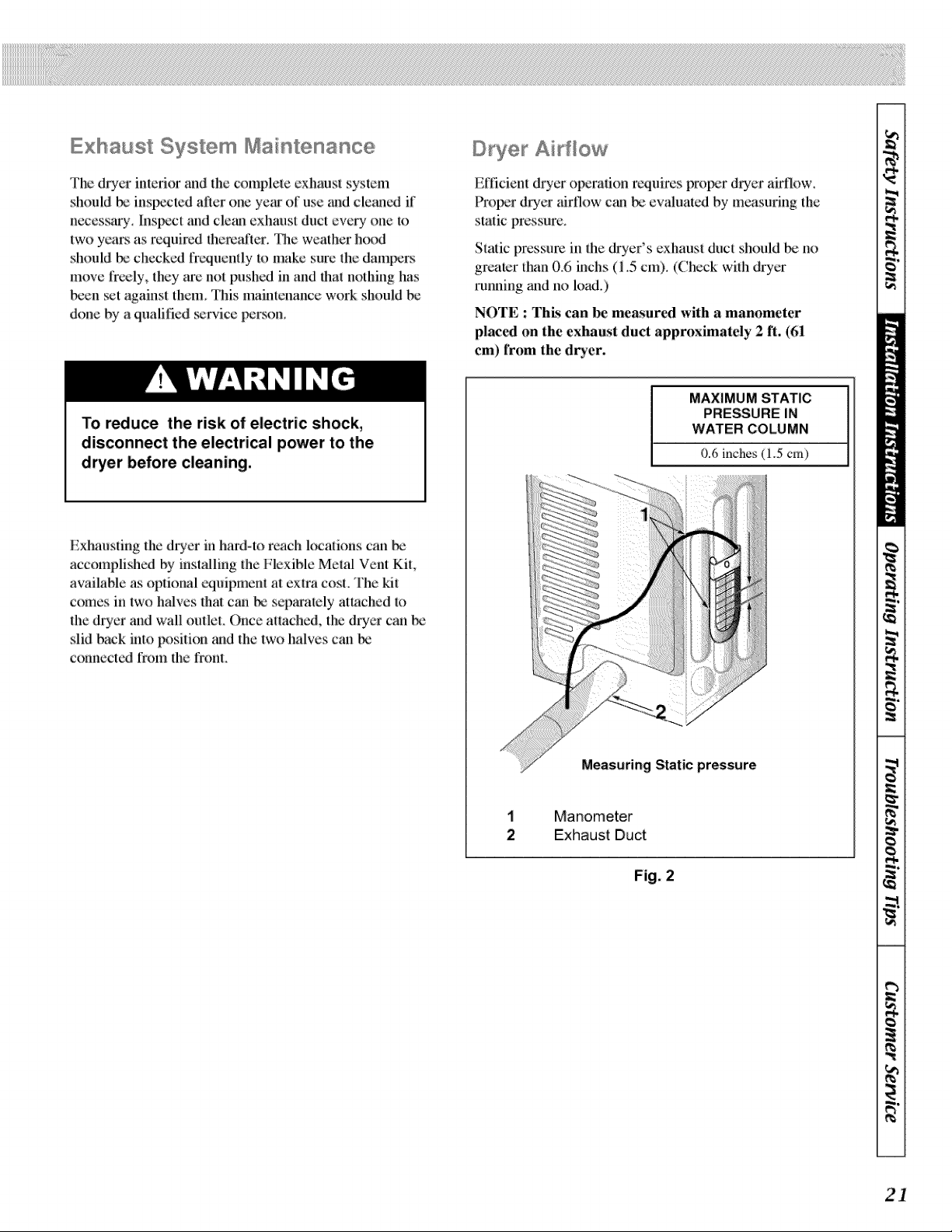

Dryer Airflow

Efficient dryer ope:ration requires prot_r dryer airtlow.

Proper d:ryer airflow can _ ew_luated by measuring tile

static pressure.

Static pressu:m in the &'yer's exhm_st &rot should _: no

greater them 0.6 inchs (I .5 cm). (Chc:ck with dryer

:running _md no load.)

NOTE : This can be measured with a manometer

placed on the exhaust duct appruxinmtely 2 ft. (61

cm) frum the dryer.

To reduce the risk of electric shock,

disconnect the electrical power to the

dryer before cleaning.

Exhausfirig the drycr in hard-to a=ach locations can be

accomplished by installing the Flexible Metal Vent Kit,

available as optional cquipment at extra cost. The kit

comes in two halves that can bc scp_u'ately attached to

the dryer and wall outlet. Once attached, the drycr can

slid back into position m_dthe two halves cm_be

conrmcted rrom the front.

1

2

MAXIMUM STATIC

PRESSURE IN

WATER COLUMN

0.6 inches (1.5 cm)

Measuring Static pressure

Manometer

Exhaust Duct

Fig. 2

21

Loading ...

Loading ...

Loading ...