Loading ...

Loading ...

Loading ...

Form I-UDA, P/N 195673 R24, Page 32

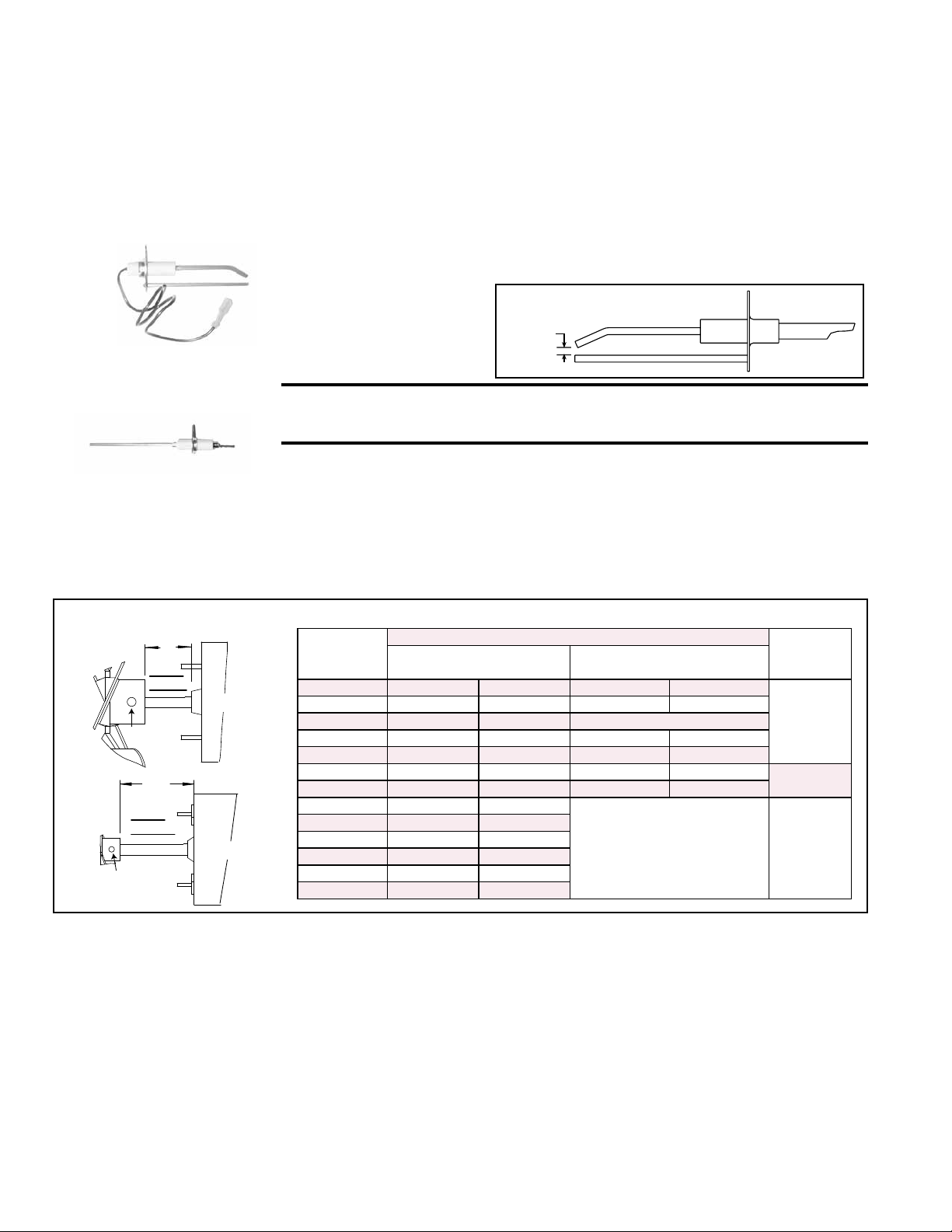

FIGURE 21 - Ignitor

showing required Spark

Gap measurement

Ignitor - Refer to FIGURE 18 and locate the ignitor. Disconnect the wire; remove the

screw and the ignitor. Clean the ignitor assembly with an emery cloth.

Spark gap must be maintained to 1/8”. See FIGURE 21.

Ignitor

CAUTION: Due to high voltage on the spark wire and electrode,

do not touch when energized. See Hazard Levels, page 2.

Flame Sensor - Refer to FIGURE 18 and locate the ame sensor. Disconnect the

wire; remove the screw and the ame sensor. Clean with an emery cloth.

Flame Sensor

Do not attempt to disassemble the control module. However, each heating season

check the lead wires for insulation deterioration and good connections.

Proper operation of the direct spark ignition system requires a minimum ame signal

of 1.0 microamps as measured by a microampmeter.

For further information and check out procedure on the direct spark ignition system,

refer to Paragraph 8.3 and the Troubleshooting Flow Chart in Paragraph 10.3.

10.2.5 Fan Motor, Fan

Blades, and Guard

Remove dirt and grease from the motor, the fan guard, and blades. Use care when

cleaning the fan blades to prevent causing misalignment or imbalance. Check that the

hub of the fan blades is secure to the shaft.

Follow these instructions for replacement of the fan guard, fan motor and/or fan

blades.

FIGURE 22 - Fan Blade Position on the Shaft by Unit Size and Type of Fan Guard

1. If the heater is installed, turn off the gas and disconnect the electric power.

2. Open the access door and disconnect the fan motor wires, capacitor wires at the

capacitor, and ground screw.

3. Remove the assembled parts (the fan guard, the motor and the fan blade).

4. Disassemble and replace whatever parts are needed and reassemble using

whatever part(s) are being replaced and the original parts.

Be sure the fan blade is in the proper position on the shaft; refer to the illustration

and table in FIGURE 22.

Position the assembly on the heater. Attach the fan guard.

Rotate the fan blade to check for adequate clearance. If adjustment is required,

loosen the mounting screws, re-position the fan guard, and tighten the screws.

Rotate the fan blade and re-check for adequate clearance. Repeat this procedure

until the assembly is positioned properly.

10.0 Maintenance

and Service

(cont’d)

10.2 Maintenance

Procedures

(cont’d)

10.2.4 Ignition System (cont’d)

UDAP/UDAS

Size

A = Fan Spacing

Setscrew

Torque

(in/lbs ±10)

Standard Wire Fan Guard

with .5” (13mm) Spacing

Option AZ8 Wire Fan Guard

with .334” (8.5mm) Spacing

30 1” 25 mm 1” 25 mm

80

45 9/16” 14 mm 1-1/16” 27 mm

45-LN 3/4” 19 mm N/A

60 1-1/2” 38 mm 1-3/4” 44 mm

75 2-1/8” 54 mm 1-1/2” 38 mm

100 2-3/8” 60 mm 2-3/8” 60 mm

120

125 2-5/16” 59 mm 2-1/8” 54 mm

150 2-3/8” 60 mm

N/A 130

175 2-1/8” 54 mm

200 1-5/8” 41 mm

225/250/300 2” 51 mm

350 1-7/8” 48 mm

400 1-3/8” 35 mm

A

Fan

Blade

Sizes

30-250

Motor

Setscrew

A

Sizes

300-400

Motor

Fan

Blade

Setscrew

Loading ...

Loading ...

Loading ...