Loading ...

Loading ...

Loading ...

General Competition Maintenance

Servicing Your Honda 29

Brake Fluid Replacement

Refer to Brake Pad Wear on page 122.

Brake Caliper Inspection: Be sure both the front and rear

calipers are able to move freely on the caliper pin and caliper

bracket pins. Check pad thickness periodically and replace the

pads when minimum thickness is reached. If the brakes fade

when they are hot, inspect the pads for glazing or damage, and

replace if necessary.

Brake Fluid Replacement: Refer to an official Honda Service

Manual (page 186) for brake fluid replacement instructions.

Replace the brake fluid in the brake system every 2 years.

Replace the fluid more frequently if you subject your brakes to

severe use. Heavy braking heats the brake fluid and it may

deteriorate sooner than expected. Any type of riding, that

requires frequent use of the brakes, such as in tight woods, can

shorten the service life of brake fluid.

Bleed Hole

After every moto (CRF250R)/race (CRF250RX), check the bleed

hole below the water pump cover for leakage. Clean away any

clogged dirt or sand, if necessary. Check the bleed hole of the

water pump for signs of seal leakage. If water leaks through the

bleed hole, replace the mechanical seal. If oil leaks through the

bleed hole, replace the oil seal. Make sure that there is no

continuous coolant leakage from the bleed hole while operating

the engine. A small amount of coolant weeping from the bleed

hole is normal. See an official Honda Service Manual (page 186)

or consult your dealer (page 188) for replacing the mechanical

seal or oil seal. Both seals should be replaced at the same time.

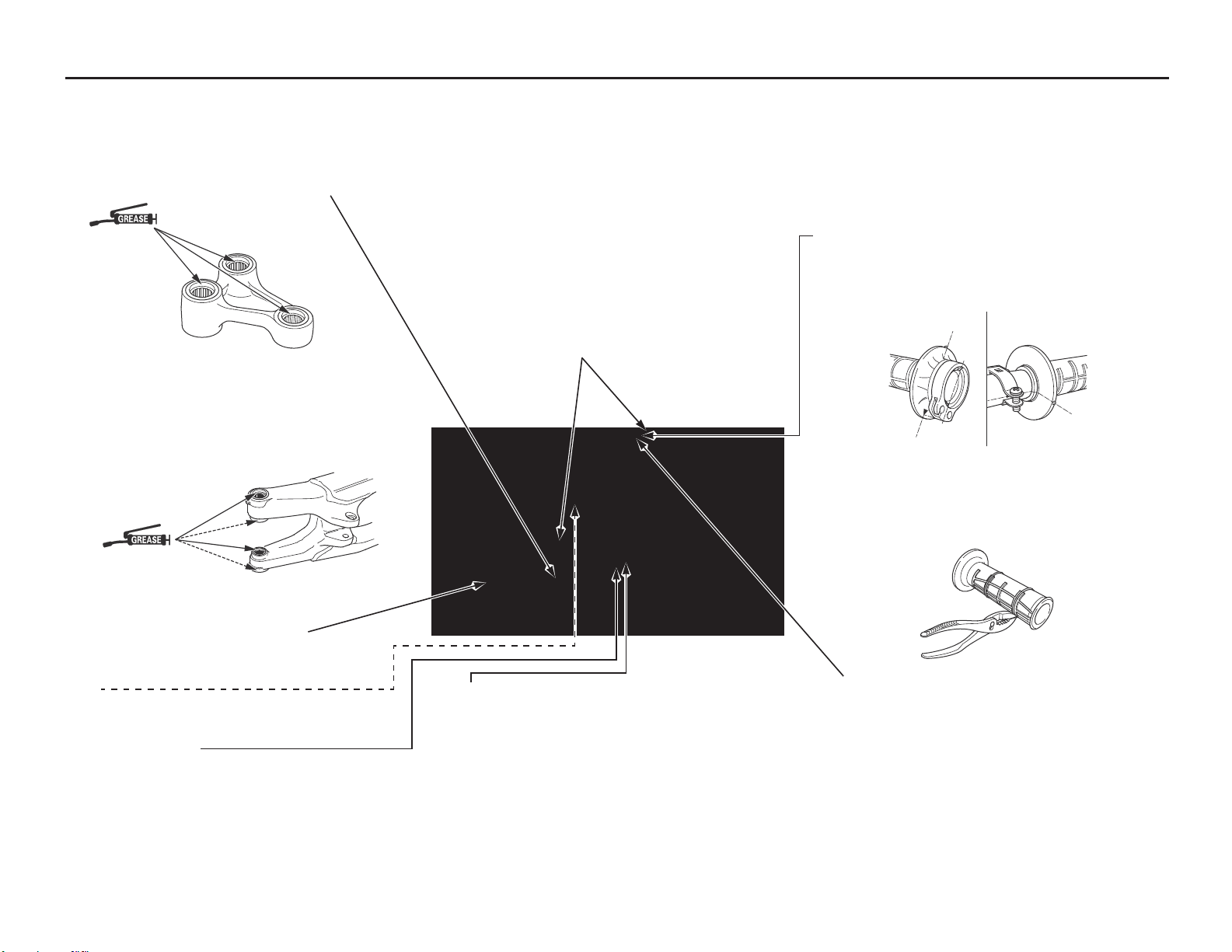

Suspension Linkage Lubrication

Disassemble, clean, inspect and lubricate all suspension linkage

pivot bearings with molybdenum disulfide grease (containing

more than 3% molybdenum disulfide additive Moly Paste 77)

after each 7.5 hours of running time in order to maintain proper

suspension performance and minimize component wear.

Swingarm

Do not attempt to weld or otherwise repair a damaged

swingarm. Welding will weaken the swingarm.

Swingarm Pivot Lubrication

Clean, inspect and lubricate the swingarm and suspension

linkage pivots with molybdenum disulfide grease (containing

more than 3% molybdenum disulfide additive Moly Paste 77)

after each 7.5 hours of running time in order to maintain

proper suspension performance and minimize component

wear. Be sure all of the dust seals are in good condition.

Handgrips

Always use Pro Honda Handgrip Cement or an equivalent

when replacing handgrips.

Refer to an official Honda Service Manual (page 186) for

installation instructions.

Throttle Grip/Handlebar Grip

Right throttle grip: Align the index mark on the throttle grip

with the index mark of the throttle pipe.

Left handlebar grip: Align the index mark on the left

handlebar grip with the paint mark on the handlebar.

For added security, you may choose to bind the handgrips to

the handlebar and throttle pipe with safety wires to prevent the

possibility of them loosening. Position the twisted wire ends

away from your palms and be sure to bend the wire ends well

into the handgrip rubber so they will not snag your glove.

Throttle Control

Remove the throttle control every few rides, clean the inside

of the throttle pipe and handlebar thoroughly. Inspect the cable

carefully for kinks or other damage that may restrict throttle

control in anyway. Move the handlebar from lock to lock to be

sure there is no cable interference. Make certain the throttle

operation is perfect after servicing and inspecting.

Fuse

Check the fuse before looking elsewhere for the cause of

an electrical problem.

Engine Oil and Filter

Drain and replace engine oil often to ensure the greatest

service life of the piston, cylinder, crankshaft,

transmission and clutch.

Also replace engine oil filter often to ensure the greatest

service life. Frequent changes will also assure consistent

performance of power, response, both shifting and

clutch action (page 65).

Loading ...

Loading ...

Loading ...