Loading ...

Loading ...

Loading ...

Front Suspension Adjustments

Adjustments for Competition 145

Front Suspension Adjustments

The front suspension can be adjusted for the rider's

weight and riding conditions by using one or more

of the following methods:

• Oil volume — The effects of higher or lower

fork oil capacity are only felt during the final

3.9 in (100 mm) of fork travel.

• Compression damping — Turning the

compression damping adjuster (1) adjusts how

quickly the fork compresses.

• Rebound damping — Turning the rebound

damping adjuster (2) adjusts how quickly the

fork extends.

• Fork springs — Optional springs are

available in soft and stiff types than the

standard rate. (page 182)

The inverted fork on your CRF features sealed

damper cartridges with dual (separate air and oil)

chambers to prevent aeration. The design also

isolates the oil in each fork/damper, which may

contain air bubbles and/or metal particles, from the

sealed cartridge to provide more consistent

damping.

Air is an unstable gas which builds up pressure as it

is worked (such as in a fork). Air pressure acts as a

progressive spring and affects the entire range of

fork travel. This means the fork action on your CRF

will get stiffer during a moto (CRF250R)/race

(CRF250RX). For this reason, release built-up air

pressure in the fork legs between motos

(CRF250R)/races (CRF250RX). Be sure the fork is

fully extended with the front tire off the ground

when you release the pressure.

The standard air pressure is 0 psi (0 kPa, 0 kgf/cm

2

).

You may relieve accumulated air pressure in the fork

legs by using the air pressure release screws. The

front wheel should be off the ground before you

release the pressure. The air pressure should be

adjusted according to the altitude and outside

temperature.

1. Place an optional workstand under the engine,

so that the front wheel is off the ground.

Do not adjust air pressure with the front wheel

on the ground as this will give false pressure

readings.

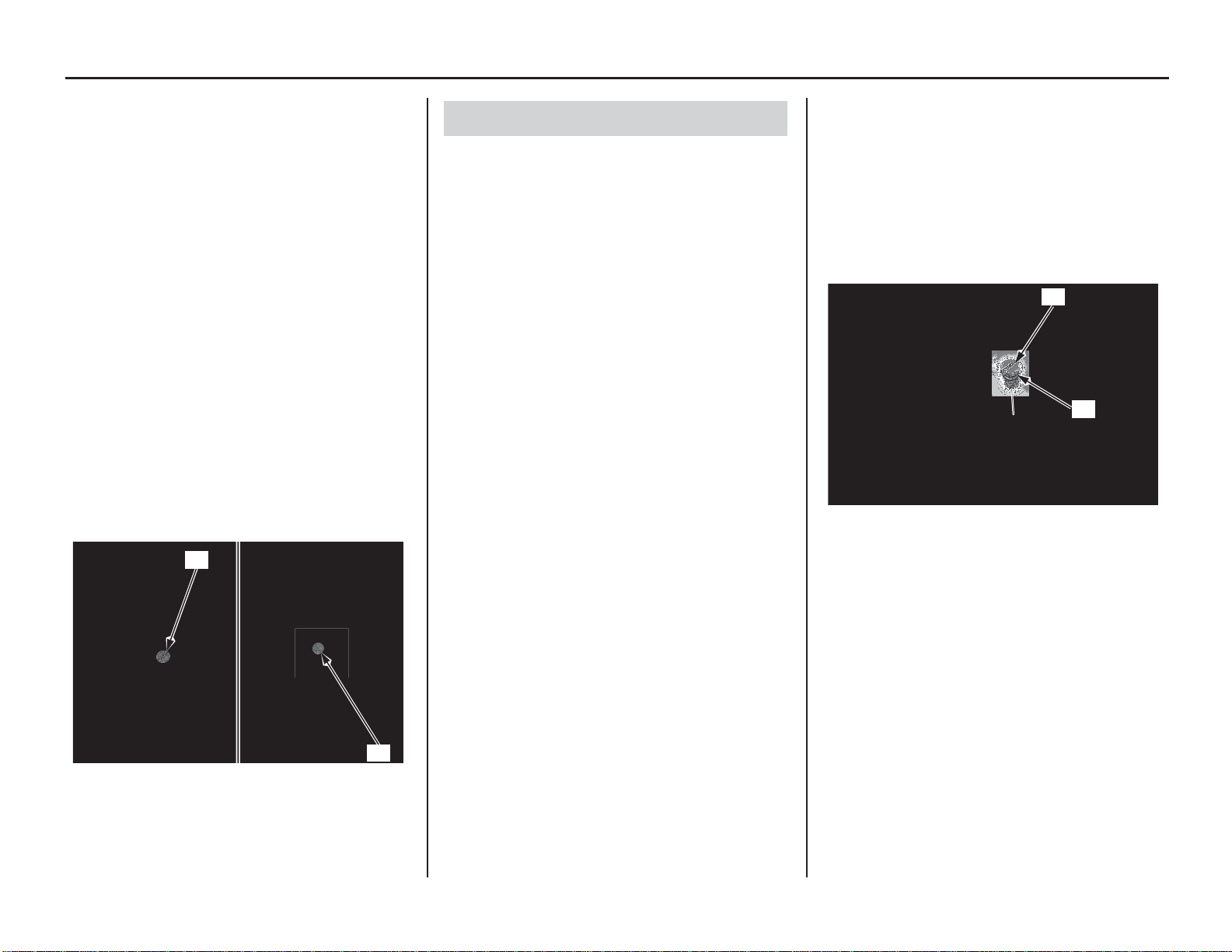

2. Remove the air pressure release screw (1).

3. Apply recommended fork oil to a new O-ring

(2), and then install the new O-ring.

4. Install and tighten the air pressure release

screw to the specified torque:

1.0 lbf·ft (1.3 N·m, 0.1 kgf·m)

The procedure is the same for the both right and

left fork legs.

(1) compression damping adjuster

(2) rebound damping adjuster

(1)

(2)

Front Suspension Air Pressure

(1) air pressure release screw (2) O-ring (new)

(2)

(1)

Loading ...

Loading ...

Loading ...