Loading ...

Loading ...

Loading ...

26

EN

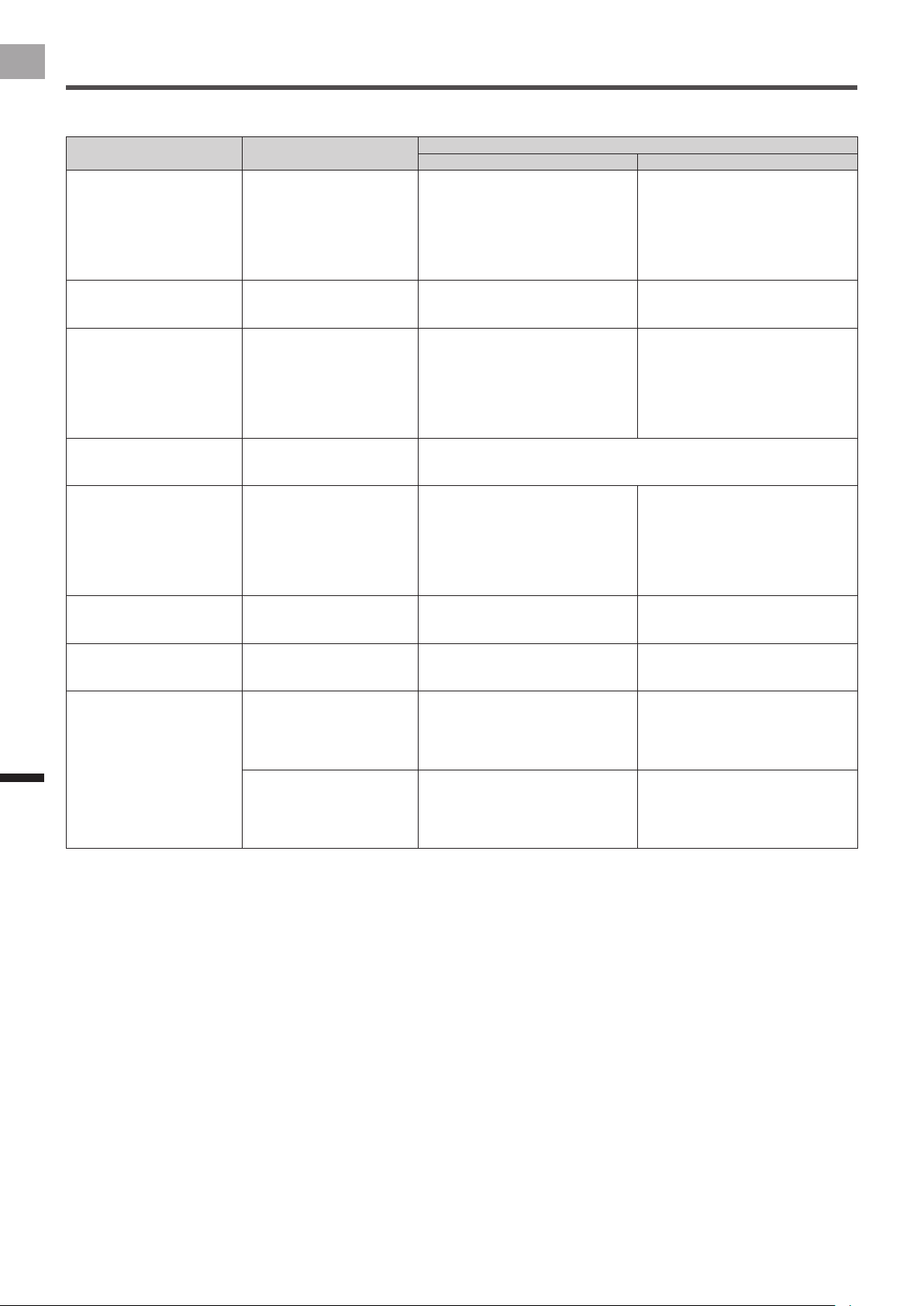

Troubleshooting

Troubleshooting

Magnet

Symptom Cause

Solution

User Dealer

I cannot install the magnet on

the chainstay.

The installation of the magnet

or the selected magnet type is

incorrect.

― There are two types of magnets, patch

type and arm type.

You need to choose the appropriate

type depending on the distance

between the magnet and the left

transmitter or the junction box, and the

shape of the frame.

The left transmitter and chain

ring adapter are obstructing

the magnet.

The installation of the magnet

or the selected magnet type is

incorrect.

― Measure the distance from the sensor

to the magnet, and install the magnet

correctly.

The arm type magnet rattles. The cable ties for xing the

magnet arm in place have

become loose. Or, the screws

for adjusting it have become

loose. Or, the cushions for

installation have deteriorated.

Contact your dealer. Check if the magnet is installed

correctly. The cable ties and cushions

are consumables. Replace them if

they have stretched or become loose

because of age or deterioration.

If replacements are needed, please

visit our website.

The magnet is rubbing. A stone or something is stuck

in the gap between the magnet,

transmitter, and junction box.

Remove any stones or other things stuck in the gap and use a damp rag to

clean the magnet and the sensor.

Stones or other things stuck in the equipment may damage it.

Magnet calibration fails. The magnet calibration was not

nished while in the magnet

calibration mode.

― Check the magnet calibration

mode. The system exits this mode

automatically after 30 minutes. Also,

pushing the push switch on the

right transmitter during the magnet

calibration mode cancels this mode

and the LEDs blink orange 5 times.

The left and/or right LEDs

light red when the magnet

calibration is nished.

The magnet has been detected

correctly less than 6 times.

― Conrm that the LEDs of the left and

right transmitters light green more than

7 times.

During magnet calibration, the

red LED lights when a magnet

passes a sensor.

Crank rotation is too fast. ― The crank rotation speed should be

less than one rotation per second.

During magnet calibration, the

LED does not light when a

magnet passes a sensor.

The installation of the magnet

has been done incorrectly.

― Check the magnet installation. The

LED will not light when the crank is

rotated if magnets are not positioned

correctly and/or if they are too far from

the sensor.

A magnet other than the

provided magnets is attached

to the frame.

― Check if there is a magnet other than

the provided magnets attached to the

frame. This product will not operate

properly if there are magnets installed

for another brand of power meter, etc.

Loading ...

Loading ...

Loading ...