Loading ...

Loading ...

Loading ...

assembly

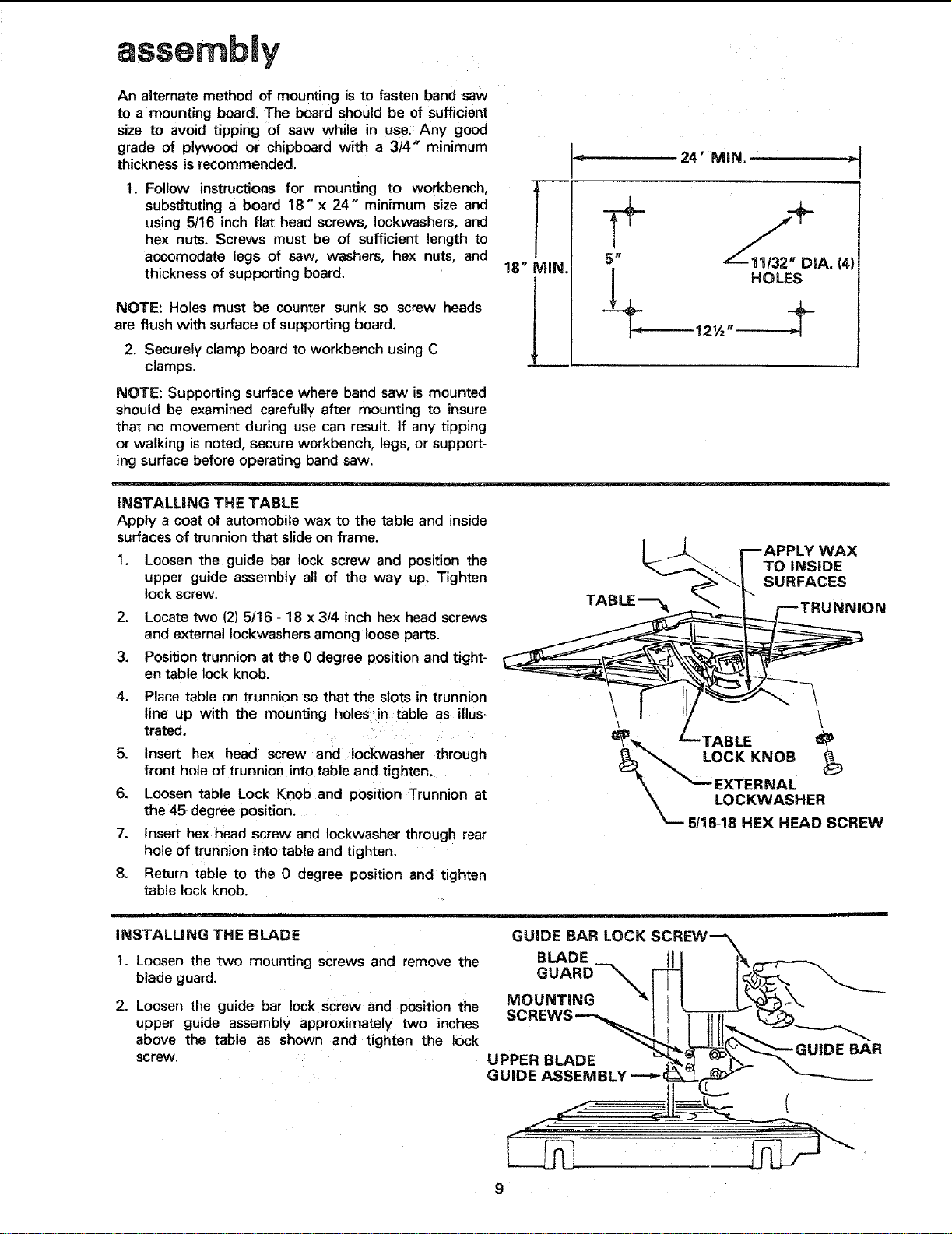

An alternate method of mounting is to fasten band saw

to a mounting board, The board should be of sufficient

size to avoid tipping of saw while in use: Any good

grade of plywood or chipboard with a 3/4" minimum

thickness is recommended.

1. Follow instructions for mounting to workbench,

substituting a board 18" x 24" minimum size and

using 5116 inch flat head screws, Iockwashers, and

hex nuts. Screws must be of sufficient length to

accomodate legs of saw, washers, hex nuts, and

thickness of supporting board.

NOTE: Holes must be counter sunk so screw heads

are flush with surface of supporting board.

2. Securely clamp board to workbench using C

clamps.

J

18" MBN.

!

24' MIN.

5" . (4)

HOLES

12½"-----_

NOTE: Supporting surface where band saw is mounted

should be examined carefully after mounting to insure

that no movement during use can result. If any tipping

or walking is noted, secure workbench, legs, or support-

ing surface before operating band saw.

iNSTALLiNG THE TABLE

Apply a coat of automobile wax to the table and inside

surfaces of trunnion that slide on frame.

1. Loosen the guide bar lock screw and position the

upper guide assembly all of the way up. Tighten

lock screw.

2. Locate two (2) 5/16 - 18 x 3!4 inch hex head screws

and external Iockwashers among loose parts.

3. Position trunnion at the 0 degree position and tight-

en table lock knob.

4. Place table on trunnion so that the slots in trunnion

line up with the mounting holes in table as illus-

trated.

5. Insert hex head screw and Iockwasher through

front hole of trunnion into table and tigntan.

6. Loosen table Lock Knob and position Trunnion at

the 45 degree position.

7. Insert hex head screw and Iockwasher through rear

hole of trunnion into table and tighten.

8. Return table to the 0 degree position and tighten

table lock knob.

__.. mAPPLY WAX

TO iNSiDE

SURFACES

TABLE'--'_ _._TRUNN,ON

--TABLE _P

LOCK KNOB _

EXTERNAL

,,,o °?2Wx"S"22

iNSTALLING THE BLADE

1. Loosen the two mounting screws and remove the

blade guard.

2. Loosen the guide bar lock screw and position the

upper guide assembly approximately two inches

above the table as shown and tighten the lock

screw.

Loading ...

Loading ...

Loading ...