Loading ...

Loading ...

Loading ...

assembUy

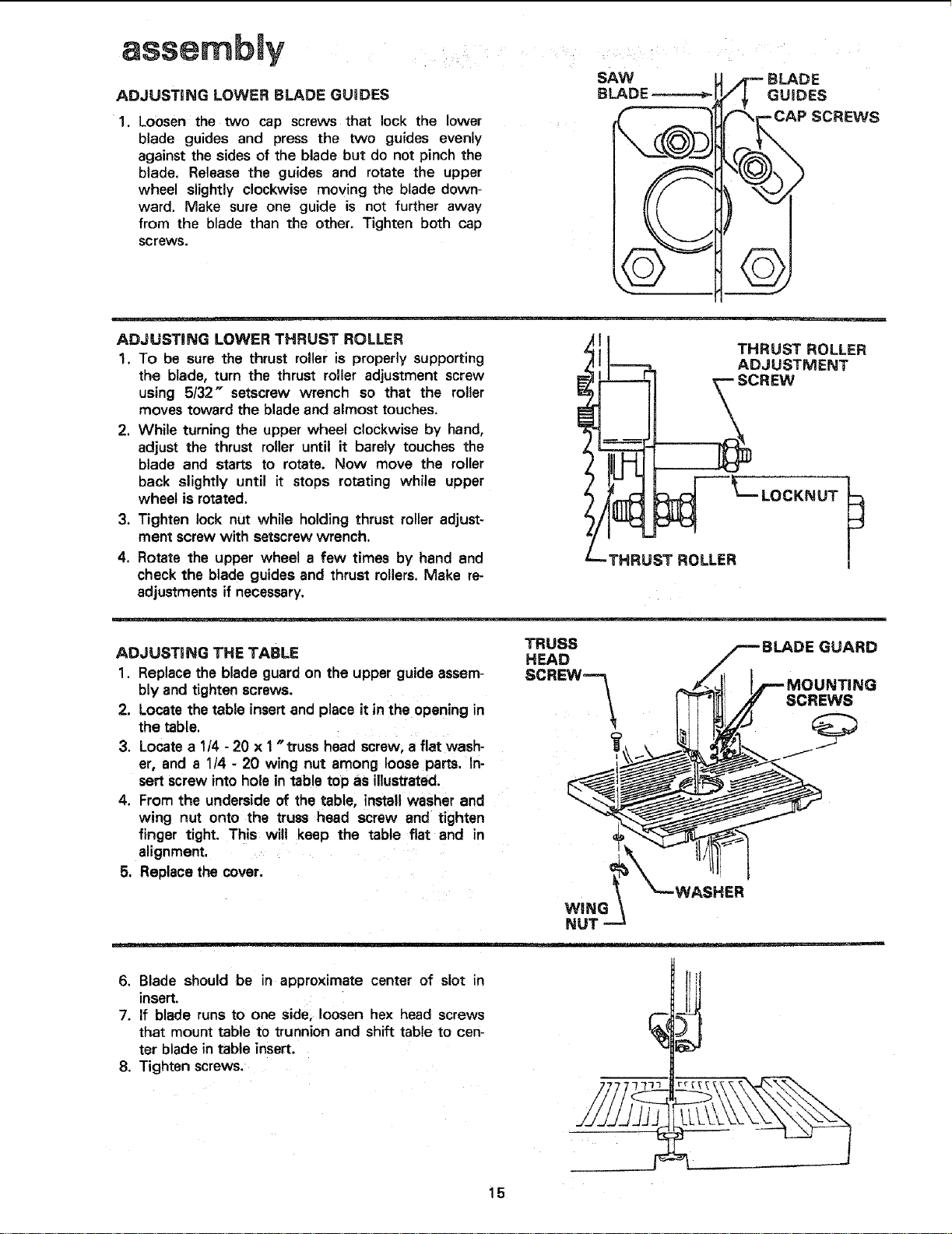

ADJUSTING LOWER BLADE GUIDES

1. Loosen the two cap screws that lock the lower ....

blade guides and press the two guides evenly

against the sides of the blade but do not pinch the

blade. Release the guides and rotate the upper

wheel slightly clockwise moving the blade down-

ward. Make sure one guide is not further away

from the blade than the other. Tighten both cap

screws.

SAW

BLADE

BLADE

GUIDES

SCREWS

ADJUSTING LOWER THRUST ROLLER

1. To be sure the thrust roller is properly supporting

the blade, turn the thrust roller adjustment screw

using 5/32" setscrew wrench so that the roller

moves toward the bladeand almost touches.

2. While turning the upper wheel clockwise by hand,

adjust the thrust roller until it barely touches the

blade and starts to rotate. Now move the roller

back slightly until it stops rotating while upper

wheel is rotated.

3. Tighten lock nut while holding thrust roller adjust-

ment screw with setscrew wrench.

4. Rotate the upper wheel a few times by hand and

check the blade guides and thrust rollers. Make re-

adjustments if necessary.

THRUST ROLLER

ADJUSTMENT

__SCREW

-THRUST ROLLER

ADJUSTING THE TABLE

1. Replacethe blade guard on the upper guide assem-

bly and tighten screws.

2. Locate the table insertand place it in the opening in

the table.

3. Locate a 114- 20 x 1"truss head screw, a flat wash-

er, and a 1/4 - 20 wing nut among loose parts. In-

sert screw into holein table top as illustrated.

4. From the underside of the table, install washer and

wing nut onto the truss head screw and tighten

finger tight. This will keep the table flat and in

alignment.

5, Replacethe cover.

TRUSS GUARD

HEAD

SCREW=-_ 3

SCREWS

6. Blade should be in approximate center of slot in

insert.

7. If blade runs to one side, loosen hex head screws

that mount table to trunnion and shift table to cen-

ter bladein table insert.

8. Tighten screws.

7777

JJJJJ

15

Loading ...

Loading ...

Loading ...