Loading ...

Loading ...

Loading ...

assembly

BLADE GUIDES-_

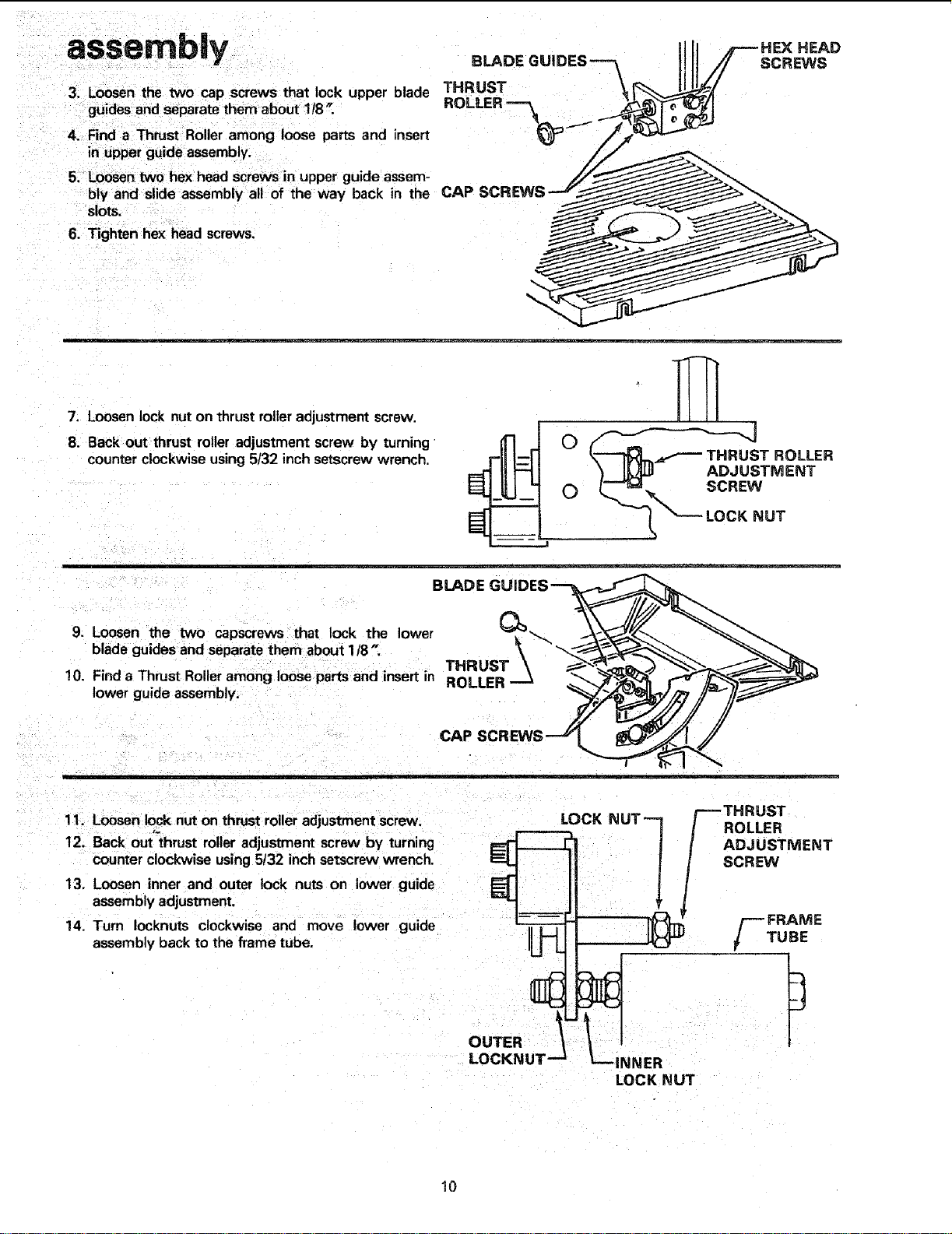

3. Loosen the two cap screws that lock upper blade THRUST \

guidesand separate them about 1/8_. ROLLER _ .

4. Find a Thrust Rolleramong loose parts and insert _

in upperguido assembly.

5. Loosentwo hex head screws in upper guide assem-

bly and slide assembly all of the way back in the CAP

slots.

6. Tighten hex headscrews,

SCREWS

7. Loosen lock nut on thrust roller adjustment screw.

8. Back out thrust roller adjustment screw by turning

counter clockwise using 5/32 inch setscrew wrench.

J

JST ROLLER

ADJUSTMENT

SCREW

BLADE GUIDES ___

9. Loosen the two capscrews that lock the lower _____'_//_# _"_

bladeguides and separatethem about 1/8". _ '

10. Find a Thrust Rolleramong loose partsand insert in THRUST __

lower guide assembly. ROLLER _

i

11, Loosen lock nut on thrust roller adjustment screw,

12. Back out'thrust roller adjustment screw by turn=ng

counter clockwise using 5/32 inch setscrew wrench.

13. Loosen inner and outer lock nuts on lower guide

assembly adjustment.

14. Turn Iocknuts clockwise and move lower guide

assembly back to the fTame tube.

OUTER

LOCKNU1

LOCi( NUT--

--THRUST

ROLLER

ADJUSTMENT

SCREW

J

p/---FRAME

TUBE

LOCK NUT

10

Loading ...

Loading ...

Loading ...