Loading ...

Loading ...

Loading ...

6 31-5000572 Rev. 1

ENGLISH

• This manual should be given to and kept by the equipment owner.

• Before installation, please read “Safety precautions” carefully to confirm the correct installation.

• The installing technician should preform a test run and trial operation to confirm performance and a completed

installation. Provide the users guide and installation manual to the equipment owner.

• Take appropriate measures to insure that the building structure can bear the weight of the equipment. Structural failure

can cause damage or personal injury.

• The installation should include measures to protect the equipment against severe weather and earthquakes.

• Use only Haier accessories and components with this equipment. Use of unapproved or 3rd party accessories could

result in water damage, electrical shock or fire.

• Terminate all condensate drains in accordance to local or national codes. Improper connection to building drains can

introduce poisonous gasses or objectionable odors.

• Condensate drain lines should be installed according to this manual. Be sure to insulate drain lines to avoid

condensation and water damage.

• Both the liquid and gas refrigeration lines should be insulated or condensate water damage could occur.

• All refrigerant flare connections must be properly torqued using a torque wrench with a back up. Torque specifications

are listed in this manual. Improperly tightened flare fittings can cause leaks and displace oxygen in confined spaces.

• Consideration should be given for locating the outdoor equipment. Air discharging from equipment can damage plants

and vegetation.

• Follow equipment clearance requirements when installing this equipment. Adequate clearance should be given for

service access and maintenance.

• Refrigerant lines should be insulated otherwise loss of capacity or water leakage could result.

• Refrigerant lines should be thoroughly leak tested according to this manual using dry nitrogen. Refrigerant leaks in

confined spaces can cause personal injury or death.

• Connections on this equipment have been adapted for use with R410A refrigerant including valves sizes and flare fitting

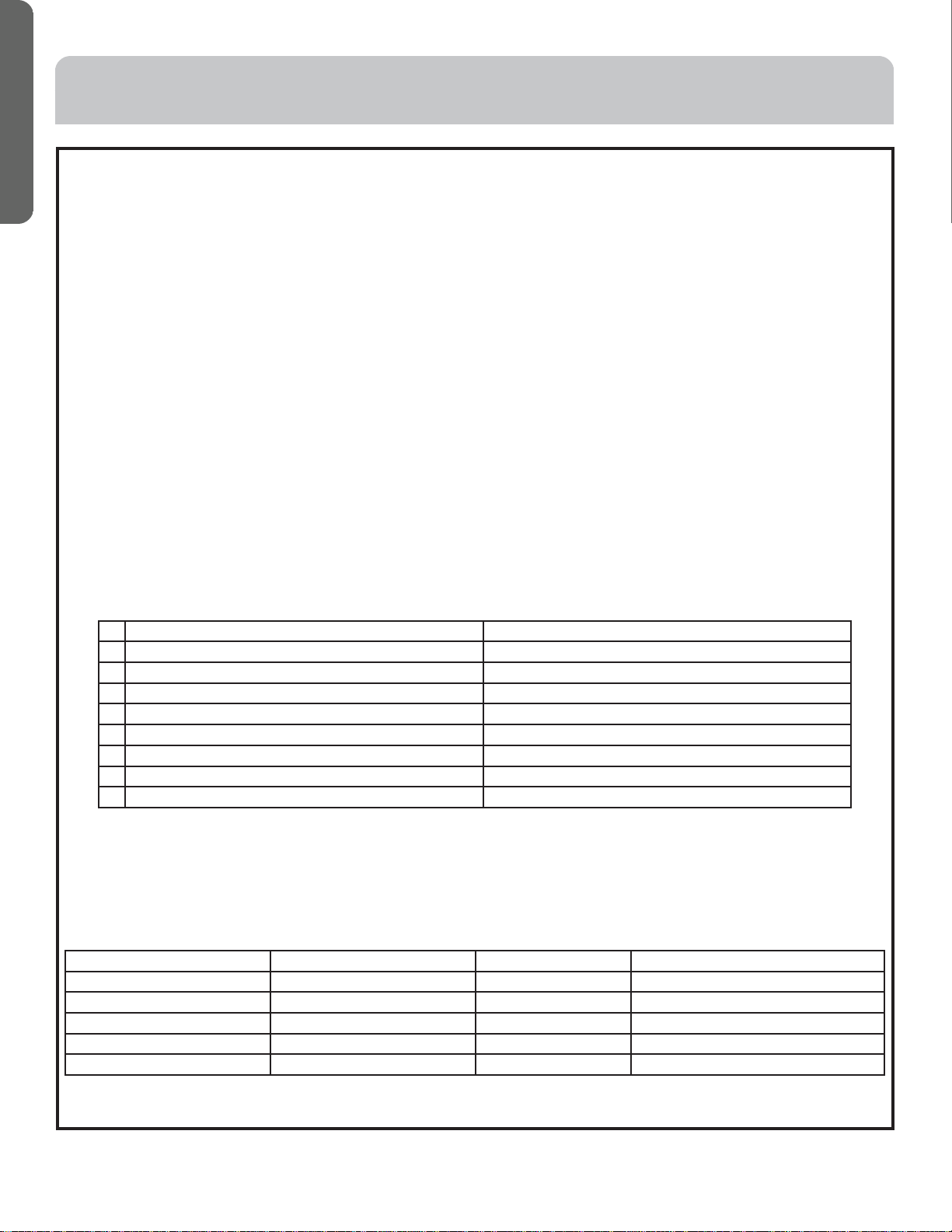

sizes. Use tools designed for use on R410A systems as seen in the table below.

Û$! ÊöóèæìĤèç÷òòïö Remarks

1 R410A Manifold guages Range: HP > 653psi, LP > 290psi

2 Charge hose Pressure: HP: 768psi, LP: 507psi

3 Electronic scale for charging R410A Do not use charging cylinders

4 Torque wrench and metric crows foot adapters

5 Û$! Êĥäõè÷òòï

6 Copper tubing cutter

7 Vacuum pump adapter Ñòöèðøö÷æòñ÷äìñæëèæîùäïùèöòõöëø÷¡òģùäïùèö

8 R410A Leak Detector Leak detectors must be designed for R410A

• Charge R410A in liquid state only.

• Maintain 4 feet clearance from televisions and radios when installing indoor and outdoor equipment to avoid signal

interference.

• Fluorescent light fixtures can disrupt equipment control signals. Please keep control and power wiring away from

fluorescent fixtures.

• You can get a frostbite if contact with leaking refrigerant.

• The flare fitting tightening torque values are listed in the following table.

Operating valve size in(mm) Fastening torque lb.ft(N.m) Fastening angle (°) Recommended tool length in(mm)

1/4(6.35) 10.33~13.28 (14~18) 45~60 5-29/32(150)

3/8(9.52) 25.08~30.98 (34~42) 30~45 7-7/8 (200)

1/2(12.7) 36.14~44.99 (49~61) 30~45 9-13/16 (250)

5/8(15.88) 50.15~60.48 (68~82) 15~20 11-13/16(300)

3/4(19.05) 61.96~72.28 (84~98) 15~20 11-13/16(300)

• Charge system using liquid refrigerant.

• Maintain 4 foot clearance with radio and TV cables to avoid signal interference or noise.

ATTENTION

Loading ...

Loading ...

Loading ...