Loading ...

Loading ...

Loading ...

DRYER

VENTING

REQUIREMENTS

(In

Australia

and

New

Zealand,

refer

to

AS/NZS

5601.1

-

Gas

Installations)

if

an

Exhaust

Hood

Cannot

be

Used

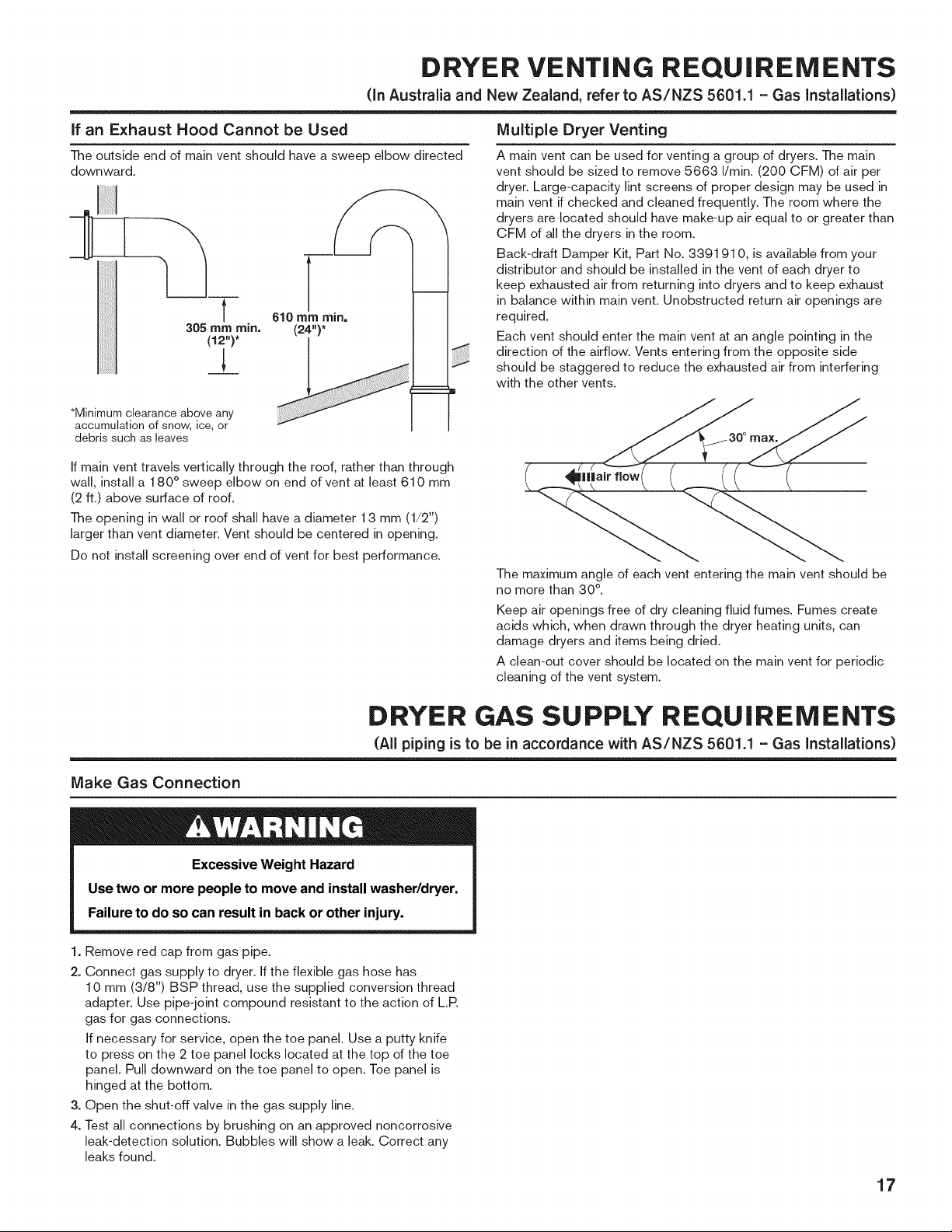

The

outside

end

of

main

vent

should

have

a

sweep

elbow

directed

downward.

610

mm

min.

(24")*

=

If

main

vent

travels

vertically

through

the

roof,

rather

than

through

wall,

install

a

180°

sweep

elbow

on

end

of

vent

at

least

610

mm

(2

ft.)

above

surface

of

roof.

305

oh

min.

"

\ \

*Minirnum

clearance

above

any

accumulation

of

snow,

ice,

or

debris

such

as

leaves

The

opening

in

wall

or

roof

shall

have

a

diameter

13

mm

(1/2")

larger

than

vent

diameter.

Vent

should

be

centered

in

opening.

Do

not

install

screening

over

end

of

vent

for

best

performance.

Multiple

Dryer

Venting

A

main

vent

can

be

used

for

venting

a

group

of

dryers.

The

main

vent

should

be

sized

to

remove

5663

I/min.

(200

CFM)

of

air

per

dryer.

Large-capacity

lint

screens

of

proper design

may

be

used

in

main

vent

if

checked

and

cleaned

frequently.

The

room

where

the

dryers

are

located

should

have

make-up

air

equal

to or

greater

than

CFM

of

all

the

dryers

in

the

room.

Back-draft

Damper

Kit,

Part

No.

3391910,

is

available

from

your

distributor

and

should

be

installed

in

the

vent

of

each

dryer

to

keep

exhausted

air

from

returning

into

dryers

and

to

keep

exhaust

in

balance

within

main

vent.

Unobstructed

return

air

openings

are

required.

Each

vent

should

enter

the

main

vent

at

an

angle

pointing

in

the

direction

of

the

airflow.

Vents

entering

from

the

opposite

side

should

be

staggered

to

reduce

the

exhausted

air

from

interfering

with

the

other

vents.

30°

max.

@ittair

flow(

The

maximum

angle

of

each

vent

entering

the

main

vent

should

be

no

more

than

30°.

Keep

air

openings

free

of

dry

cleaning

fluid

fumes.

Fumes

create

acids which,

when

drawn

through

the

dryer

heating

units,

can

damage

dryers

and

items

being

dried.

A

clean-out

cover

should

be

located

on

the

main

vent

for

periodic

cleaning

of

the

vent

system.

DRYER

GAS

SUPPLY

REQUIREMENTS

(All

piping

is

to

be

in

accordance

with

AS/NZS

5601.1

-

Gas

Installations)

Make

Gas

Connection

AWARNING

Excessive

Weight

Hazard

Use

two

or

more

people

to

move

and

install

washer/dryer.

Failure

to

do

so

can

result

in

back

or

other

injury.

1.

Remove

red

cap from

gas

pipe.

2.

Connect

gas

supply

to

dryer.

If

the

flexible

gas

hose

has

10

mm

(3/8")

BSP

thread,

use

the

supplied

conversion

thread

adapter.

Use

pipe-joint

compound

resistant

to

the

action

of

L.P.

gas

for

gas

connections.

If

necessary

for

service,

open

the

toe

panel.

Use

a

putty

knife

to

press

on

the

2

toe

panel

locks

located

at

the

top

of

the

toe

panel.

Pull

downward

on

the

toe

panel

to

open.

Toe

panel

is

hinged

at

the

bottom.

3.

Open

the

shut-off

valve

in

the

gas

supply

line.

4,

Test

all

connections

by

brushing

on an

approved

noncorrosive

leak-detection

solution.

Bubbles

will

show

a

leak.

Correct

any

leaks

found.

17

Loading ...

Loading ...

Loading ...