Loading ...

Loading ...

Loading ...

- 11

몇 CAUTION

Risk of injury and damage! Observe the

weight of the appliance when you transport

it.

When transporting in vehicles, secure

the appliance according to the guide-

lines from slipping and tipping over.

몇 CAUTION

Risk of injury and damage! Note the weight

of the appliance in case of storage.

Note

The system may only be set up by

– KÄRCHER customer service technicians

– Authorised KÄRCHER persons

Unpack the plant and sent the packaging

materials for recycling.

The following requirements are necessary

in order to install the equipment:

– frost-free room with adequate ventila-

tion and exhausts

– Floor drain for sediment basin

– Pipelines and underground construc-

tion as per drawings 0.089-491.0,

0.089-492.0 and 0.089-494.0.

– Water and electrical connection: see

"Technical data"

– horizontal, even foundation

– Protect the plant against direct sunlight

and spray water

– Sufficiently illuminate the installation site

– The floor must be freely accessible.

DANGER

Risk of electrical voltage. All electrical in-

stallations may only be done by an electri-

cian according to the local regulations.

The plant must be secured through a wrong

current protection switch with a triggering

current lesser than or equal to 30 mA.

– The appliance may only be connected

to alternating current.

– The appliance may only be connected

to an electrical supply which has been

installed by an electrician in accord-

ance with IEC 60364.

– The voltage indicated on the type plate

must correspond to the voltage of the

electrical source.

The water installation depends on the spe-

cific conditions of the existing plant compo-

nents such as

– Type and model of washing unit

– Category and type of on-site compo-

nents (sediment basin, pump basin,

etc.)

– Nominal widtht, lengths and type of

channels

Hence, the water installation must be car-

ried out according to the specific project

documents.

DANGER

Risk of injury on account of tripping and fall-

ing.

Lay the hoses of the plant in such a way

that they do not pose a risk for tripping and

falling.

A stable compressed air supply must al-

ways be ensured during operations. The

on-site air pressure system must be availa-

ble during hours of operation.

The device is designated for wall installa-

tion.

몇 CAUTION

Risk of injury, risk of damage! Check the

wall for load-bearing capacity and use suit-

able fastening material.

If a wall installation is not possible, use the

attachment kit support leg (see "Accesso-

ries").

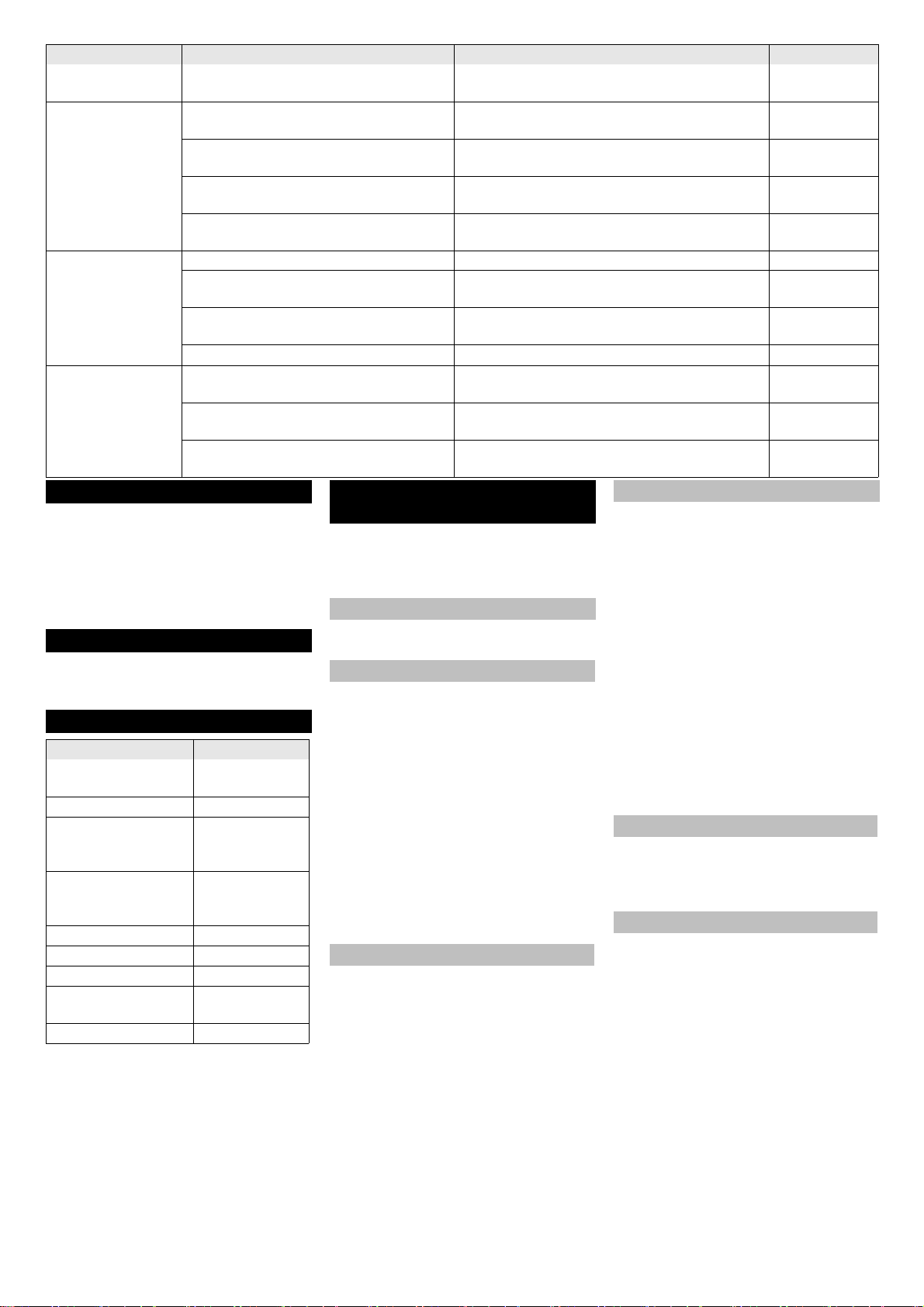

Continuous flow

sound

Float switch, control or fresh water solenoid

valve defective

Check, repair or replace the concerned component Operator, Cus-

tomer Service

Immersion pump is

not functioning

Water level in the pump basis is too low Washing system runs wit

h fresh water until level

S15

top is reached. Find the cause.

Customer Ser-

vice

Float switch S7 defective Check the float switch; clean, repair or replace it as

required

Operator, Cus-

tomer Service

Controls are defective Check, repair or replace controls Customer Ser-

vice

Immersion pump defective Check immersion pump, replace as necessary. Customer Ser-

vice

Filter output is too low Shutoff valve recycled water closed Open the shutoff valve recycled water. Operator

Immersion pump is blocked, defective Clean, repair, replace immersion pump Operator, Cus-

tomer Service

Pipe or valve is leaky, defective, blocked Check pipes and valves; clean, repair or replace as

required

Operator, Cus-

tomer Service

Pre-filter clogged. Check pre-filter and clean if necessary. Operator

Fresh water con-

sumption is too high

Float switch S9 is defective. Replace Customer Ser-

vice

Conductivity sensor (option) is defective or

contaminated.

Check; clean, replace, if required. Customer Ser-

vice

Fresh water solenoid defective Check the fresh water solenoid valve, replace if re-

quired

Customer Ser-

vice

Fault Possible cause Remedy By whom

Transport

Storage

Accessories

Accessories Order number

Recycling water con-

tainer

2.642-720.0

Additional tank 2.642-930.0

Tank connection at-

tachment kit, 2 contain-

ers

4.640-401.0

Tank connection at-

tachment kit, 3 contain-

ers

4.640-402.0

Ventilation 2.641-510.0

Overflow 2.641-995.0

Support leg 2.643-469.0

Conductivity measure-

ment

2.643-477.0

Add fresh water 2.642-113.0

Installing the unit (only for

experts)

Unpack the equipment

Preparing the installation place

Electrical connection

Water installation

Compressed air supply

Wall mount

24 EN

Loading ...

Loading ...

Loading ...