Loading ...

Loading ...

Loading ...

ADJUSTMENTS

DEPTH OF CUT ADJUSTMENTS

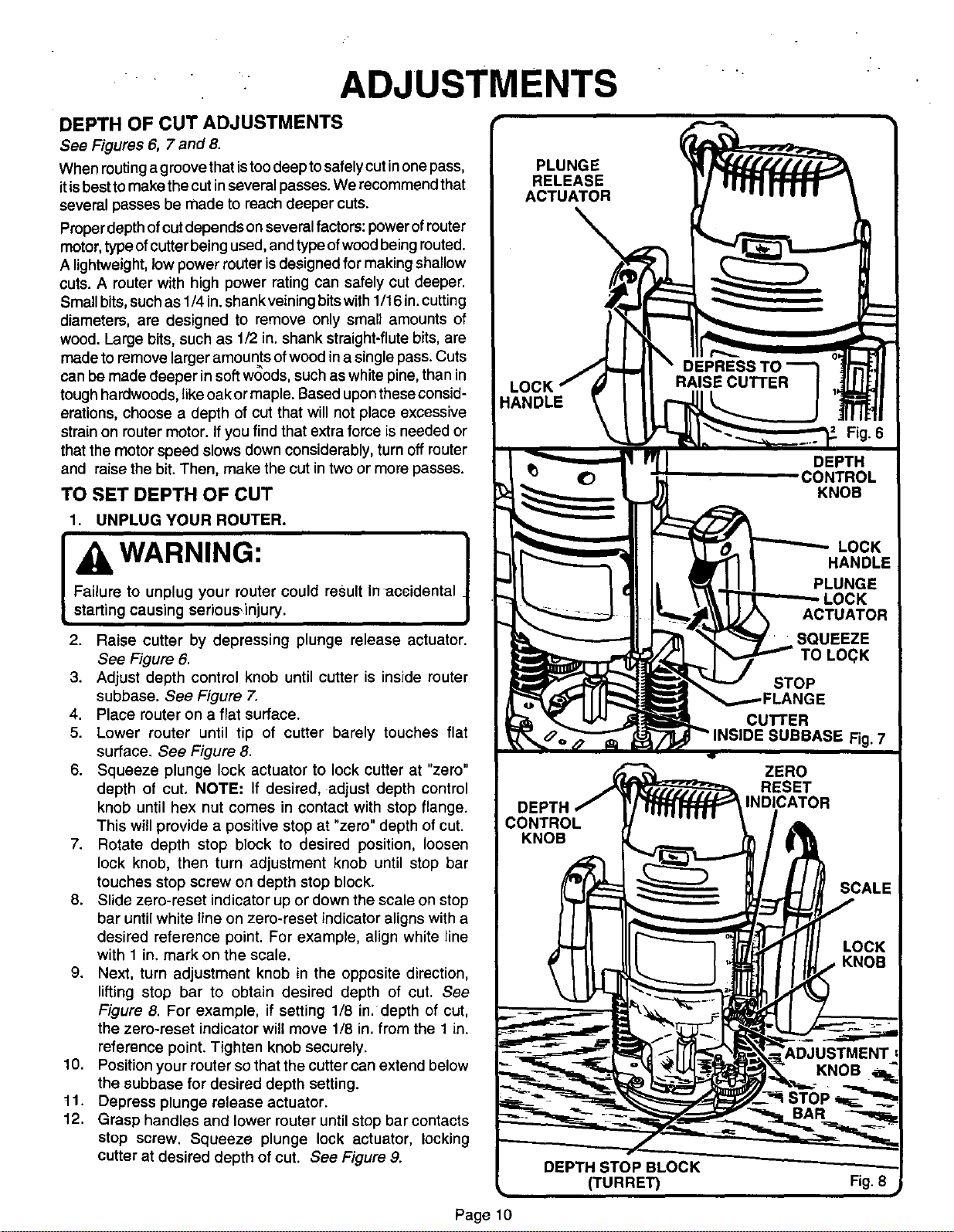

See Figures 6, 7 and 8.

When routinga groove thatistoodeep tosafelycutinone pass,

itisbesttomake thecutinseveral passes. We recommend that

several passes be made to reach deeper cuts.

Properdepthofcutdepends on severalfactors: powerofrouter

motor,typeofcutterbeing used,andtype ofwoodbeing routed.

A lightweight,low power router isdesigned for makingshallow

cuts. A router with high power rating can safely cut deeper.

Small bits,suchas 1/4 in.shank veiningbitswith1/16 in.cutting

diameters, are designed to remove only small amounts of

wood. Large bits, such as 1/2 in. shank straight-flutebits, are

made to remove larger amounts ofwood ina single pass. Cuts

can be made deeper in softwoods, such as white pine, than in

tough hardwoods,like oak or maple. Based upontheseconsid-

erations, choose a depth of cut that will not place excessive

strain on router motor. Ifyou find that extra force is needed or

thatthe motorspeed slows down considerably, turnoff router

and raise the bit.Then, make the cut in two or more passes.

TO SET DEPTH OF CUT

1. UNPLUG YOUR ROUTER.

WARNING: 1

Failure to unplug your router could result in accidental

starting causing serious_injury.

2. Raise cutter by depressing plunge release actuator.

See Figure 6.

3, Adjust depth control knob until cutter is inside router

subbase. See Figure 7.

4. Place router on a flat surface.

5. Lower router until tip of cutter barely touches flat

surface. See Figure 8.

6. Squeeze plunge lock actuator to lock cutter at "zero"

depth of cut, NOTE: If desired, adjust depth control

knob until hex nut comes in contact with stop flange.

This will provide a positive stop at "zero" depth of cut.

7. Rotate depth stop block to desired position, loosen

lock knob, then turn adjustment knob until stop bar

touches stop screw on depth stop block.

8. Slide zero-reset indicator up or down the scale on stop

bar until white line on zero-reset indicator aligns with a

desired reference point. For example, align white line

with 1 in. mark on the scale.

9. Next, turn adjustment knob in the opposite direction,

lifting stop bar to obtain desired depth of cut. See

Figure 8. For example, if setting 1/8 in. depth of cut,

the zero-reset indicator will move 1/8 in. from the 1 in.

reference point. Tighten knob securely.

10. Position your router so that the cutter can extend below

the subbase for desired depth setting.

11. Depress plunge release actuator.

12. Grasp handles and lower router until stop bar contacts

stop screw, Squeeze plunge lock actuator, locking

cutter at desired depth of cut. See Figure 9.

"IANDLE

DEPRESS T(

RAISE CUTTER

Fig. 6

D_.-I.'THSTOP BLOCK

• (TURRET) Fig. 8

Page 10

Loading ...

Loading ...

Loading ...