Loading ...

Loading ...

Loading ...

20306741

13

BLDV7 Series Gas Fireplace

FP2336

flex vent top

VENTING INSTALLATION INFORMATION

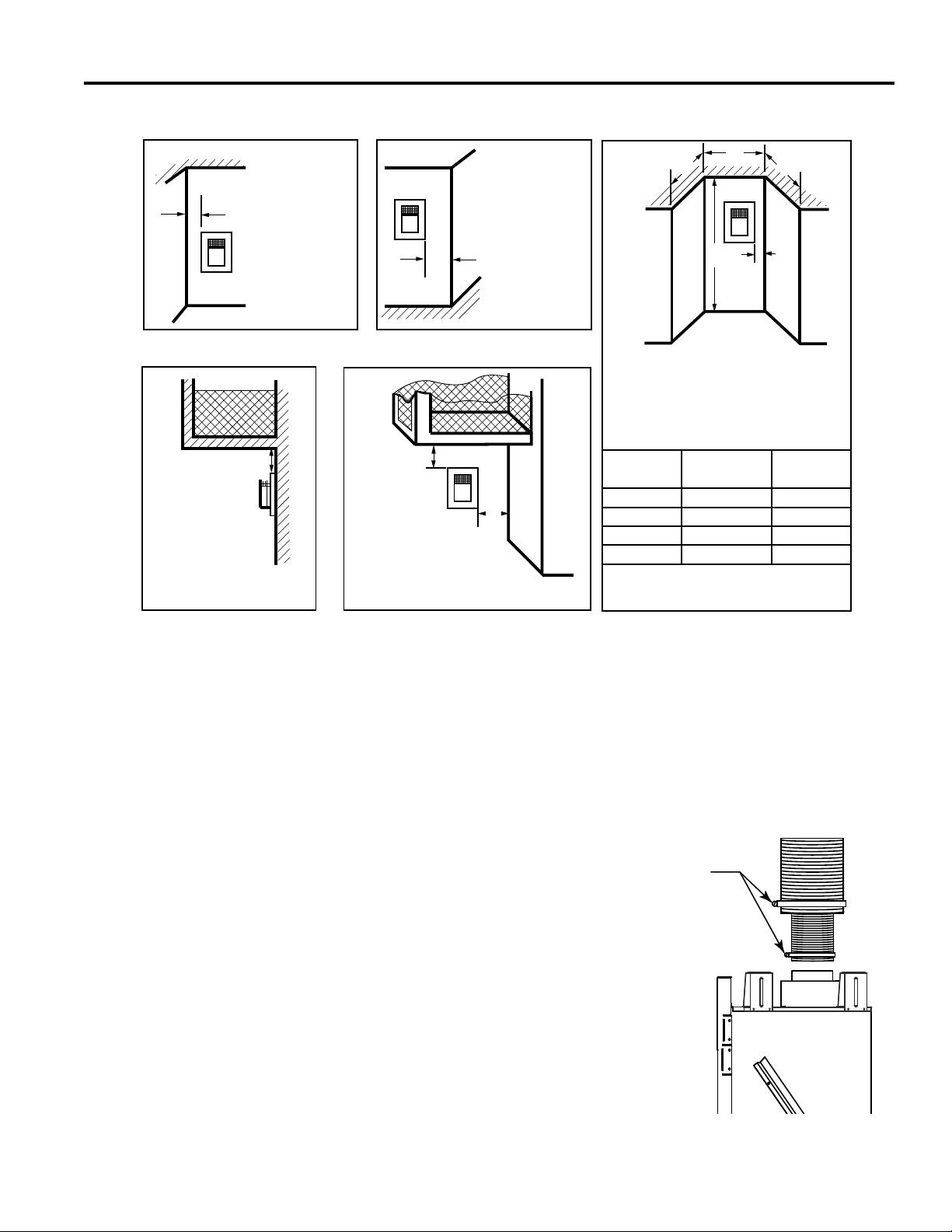

Outside Corner

Inside Corner

Termination Clearances

Termination clearances for buildings with combustible and noncombustible exteriors.

G =

Combustible

6" (152 mm)

Noncombustible

2" (51 mm)

F =

Combustible

6" (152 mm)

Noncombustible

2" (51 mm)

G

Balcony -

with no side wall

M =

Combustible &

Noncombustible

12" (305 mm)

M

Balcony -

with perpendicular side wall

M = 12" (305 mm)

P = 6” (152 mm)

M

F

Alcove Applications*

C

D

C

E

V

V

Combustible &

Noncombustible

E = Min. 2” (51 mm) for

non-vinyl sidewalls

Min. 12” (305 mm) for

vinyl sidewalls

O = 8’ (2.4 m) Min.

O

P

V

V

V

584-15

No.

of Caps DMin. CMax.

1 3’ (914 mm) 2 x DActual

2 6’ (1.8 m) 1 x DActual

3 9’ (2.7 m) 2/3 x DActual

4 12’ (3.7 m) 1/2 x DActual

DMin. = # of Termination caps x 3

CMax. = (2 / # termination caps) x DActual

*NOTE:Terminationinanalcovespace(spacesopenonlyononesideandwithanoverhang)ispermittedwiththedimensionsspeciedforvinylor

non-vinylsidingandsofts.1.Theremustbea3’(914mm)minimumbetweenterminationcaps.2.Allmechanicalairintakeswithin10’(1m)ofa

termination cap must be a minimum of 3’ (914 mm) below the termination cap. 3. All gravity air intakes within 3’ (914 mm) of a termination cap must

be a minimum of 1’ (305 mm) below the termination cap.

ASSEMBLING VENT PIPES

USA Installations

The venting system must conform to local codes and/or

the current National Fuel Code ANSI Z223.1/NFPA 54.

Only venting components manufactured or approved by

Vermont Castings Group may be used in Direct Vent sys-

tems.

Canadian Installations

The venting system must be installed in accordance with

the current CSA-B149.1 installation code.

FLEX VENT PIPES

Secureexventpipe inplacewithahoseclamp(pro-

vided).

*Besuretheexpipeoverlapsatleast1”(25mm)onto

thecollarsofthereplaceandtermination.Ifthetermi-

nation has an internal bead, be sure to overlap and se-

cure 1” (25 mm) past the bead.

* Be sure the vent is actually crushed before proceeding.

Apply a tug to be sure the vent will not slip off the collars.

Repeatprocesswith7”exventpipe.Thesameproce-

dure must be performed on the vent side.

Hose Clamp

FP2336

Figure 8 -

Secure Flex Pipe with

Hose Clamps

Figure 7 -

Termination Clearances

Loading ...

Loading ...

Loading ...