Loading ...

Loading ...

Loading ...

(2)

permit each trunnion to "'stip ' when tapped with

a mallet or plastlc-tipped hammer. (If loosened

completely, it would be almost impossib_e to

achieve an accurate Qdiustment. )

Shift the two trunnions by topping them lightly

until the two measurements described in the pre-

ceding instructions are equal. Tighten the trun-

nion screws and recheck measurements to make

sure tightening screws did nat a_ter the setting.

Several trials may be required to produce an

accurate setting.

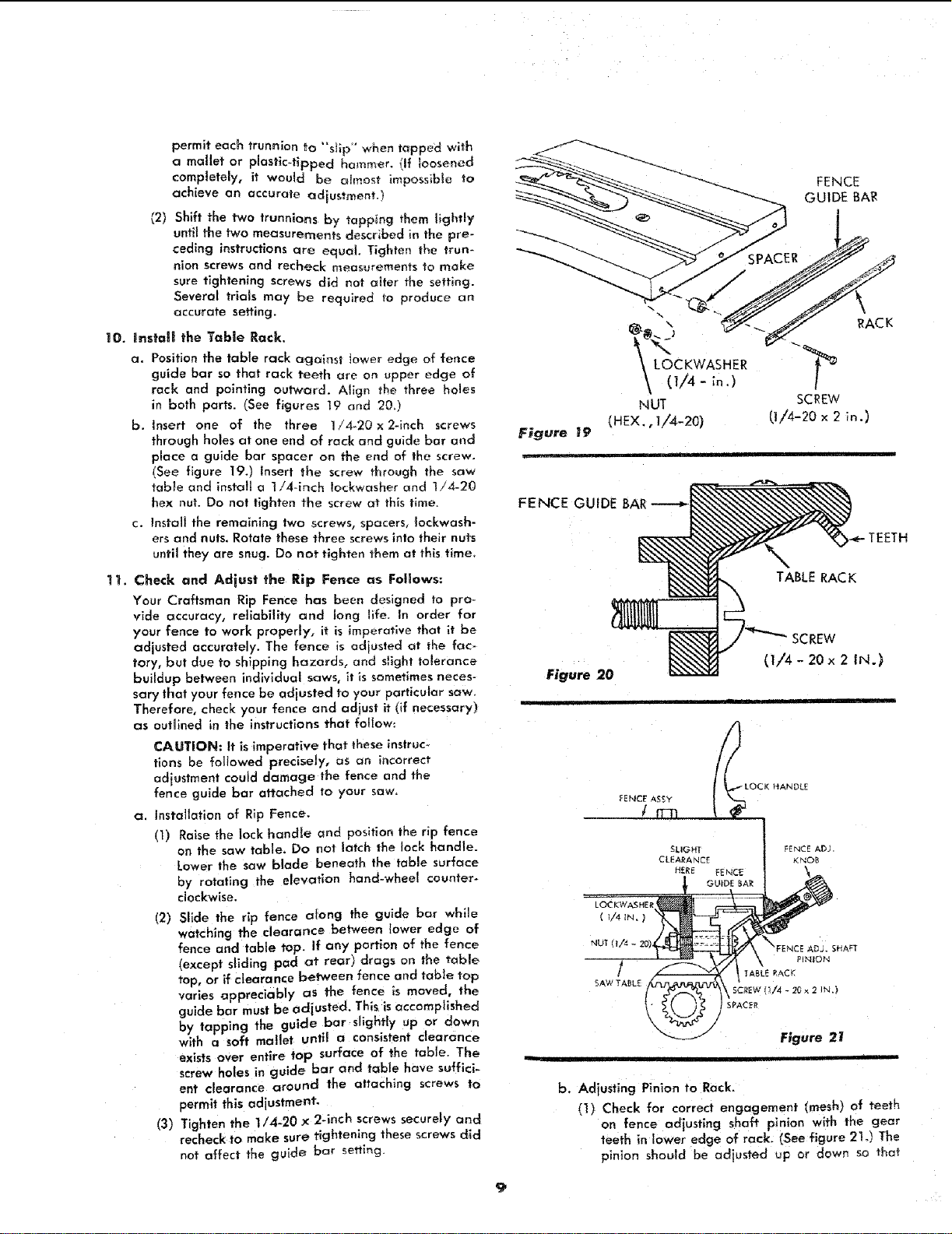

10. Ins_'ali the Table Rack,

a. Position the table rack against lower edge of fence

guide bar so that rack teeth are on upper edge of

rack and pointing outward. Align the three ho_es

in both parts. (See figures 19 and 20.)

b. Insert one of the three 1/4-20 x 2-inch screws

through holes at one end of rack and guide bar and

place a guide bar spacer on the end of the screw.

(See figure 19.) Insert the screw through the saw

table and install a 1!4-inch !ockwasher and 174-20

hex nut. Do not tighten the screw at this time.

c. Instalt the remaining two screws, spacers, Iockwash-

ers and nuts. Rotate these three screws into their nuts

until they are snug. Do not tighten them at this time,

11. Check and Adiust the Rip Fence as Follows:

Your Craftsman Rip Fence has been designed to pro-

vide accuracy, reliability and long llfe. In order for

your fence to work properly, it is imperative that it be

adjusted accurately. The fence is adjusted at the fac-

tory, but due to shipping hazards, and s_ight tolerance

buildup between individual saws, it is sometimes neces-

sary that your fence be adjusted to your particular saw.

Therefore, check your fence and adjust it (if necessary)

as outlined in the instructions that follow:

CAUTION: It is imperative that these instruc_

;'ions be followed precisely, as an incorrect

adiustment could damage the fence and the

fence guide bar attached to your saw.

a. Installation of Rip Fence.

(1) Raise the lock handle and position the rip fence

on the saw table, Do not latch the lock handle.

Lower the saw blade beneath the table surface

by rotating the elevation hand-wheel counter°

clockwise.

12) Slide the rip fence atong the guide bar while

watching the clearance between lower edge of

fence and table top. if any portion of the fence

(except sliding pad at rear) drags on the table

top, or if clearance between fence and table top

vades appreciably as the fence is moved, the

guide bar must be adius ted. This is accomplished

by tapping the guide bar slightly up or down

with a soft mallet until a consistent clearance

exists over entire top surface of the table. The

screw holes in guide bar and table have suffici-

ent clearance around the attaching screws to

permit this adjustment-

(3) Tighten the 1/4-20 × 2qnch screws securely and

recheck to make sure tightening these screws did

not affect the guide bar setting.

FENCE

GUIDE BA!R

@ \

_ LC)CKWASHER

\ fl!4

NUT

(HEX., I/4-20)

RACK

SCREW

(I/4-20 × 2 _o.)

FENCE GUIDE

TEETH

TABLE RAC K

;REW

(1/4- 20 x 2 iN.)

Figure 20

i i

LOCKWASHER

( I/4 IN. _

b. Adjusting Pinion to Rack.

(1) Check for correct engagement (mesh) of teeth

on fence adjusting shaft pinion with the gear

teeth in lower edge of rack. (See figure 21.) The

pinion should be adiusted up or down so that

Loading ...

Loading ...

Loading ...