Loading ...

Loading ...

Loading ...

(7) Rotate the tilt hand-wheel counterclockwise ap-

proximately three turns, then rotate it clockwise

until it stops. Check the saw again with the

square as shown in figure 6. If the adjustment

is correct (blade square with table surface),

tighten the set screw in the stop collar securely.

NOTE: Several trial adjustments may be re-

quired in order to produce an accurate

adjustment of the stop collar. If the first trial

fails to produce an accurate setting, it issug-

gested that the operator determine which

direction the stop collar needs to be rotated

for a correction and turn the collar in small

increments (checking each time) until the

adjustment is correct. Be sure to tighten one

of the collar set screws after each adjustment

to prevent the collar from slipping on the

tilt screw when it comes into contact with the

saw cradle.

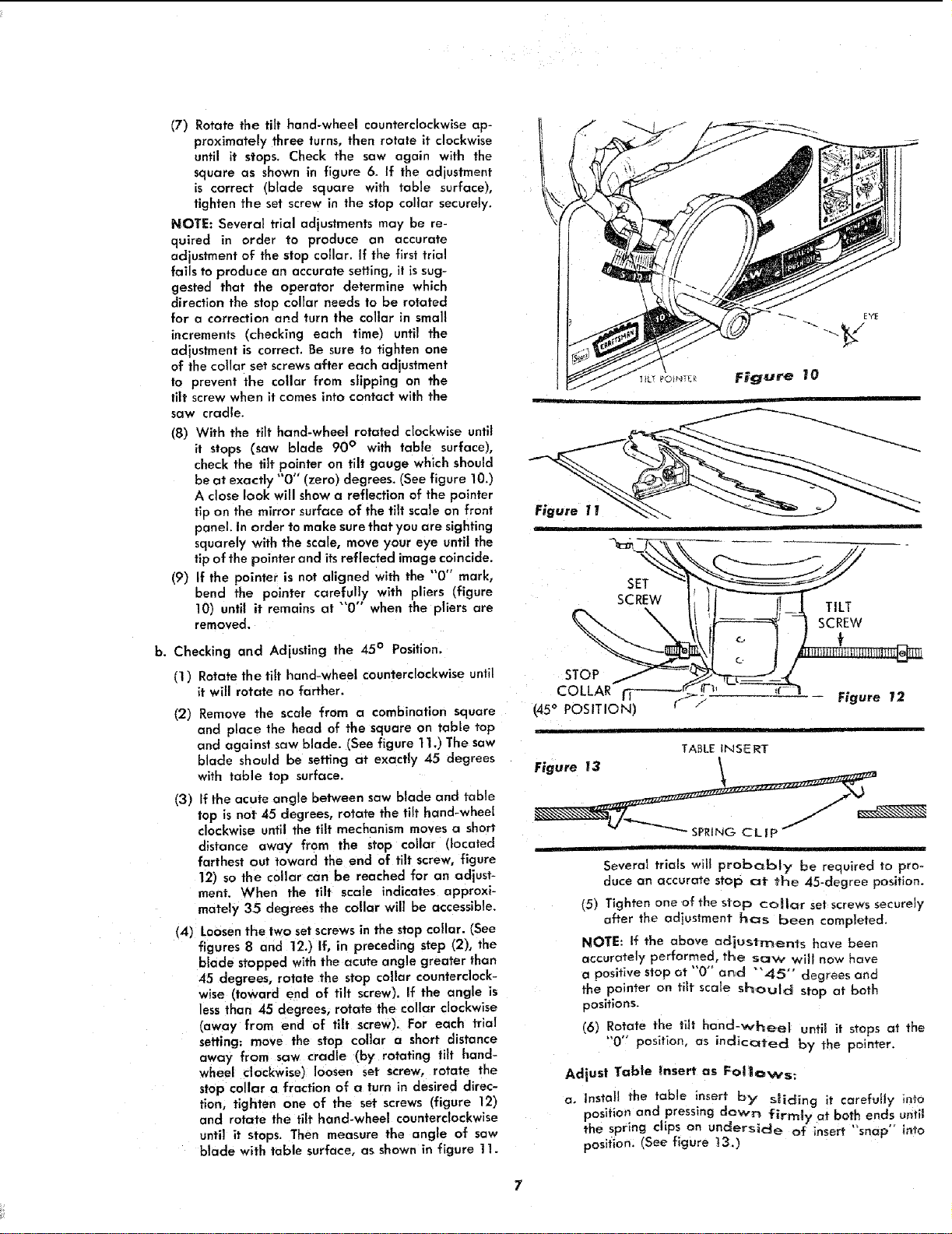

(8) With the tilt hand-wheel rotated clockwise until

it stops (saw blade 90 ° with table surface),

check the tilt pointer on tilt gauge which should

be at exactly "0" (zero) degrees. (See figure 10.)

A close look will showa reflection of the pointer

tip on the mirror surface of the tilt scale on front

panel. In order to make surethat you are sighting

squarely with the scale, move your eye until the

tip of the pointer and its reflected image coincide.

(9) If the pointer is not aligned with the "0" mark,

bend the pointer carefully with pliers (figure

10) until it remains at "'0" when the pliers are

removed.

b. Checking and Adjusting the 45° Position.

fl ) Rotate the tilt hand-wheel counterclockwise until

it will rotate no farther.

(2) Remove the scale from a combination square

and place the head of the square on table top

and against saw blade. (See figure 1I.) The saw

blade should be setting at exactly 45 degrees

with table top surface.

(3) Efthe acute angle between saw blade and table

top is not 45 degrees, rotate the tilt hand-wheel

clockwise until the tilt mechanism moves a short

distance away from the stop collar (located

farthest out toward the end of tilt screw, figure

12) so the collar can be reached for an adjust-

ment. When the tilt scale indicates approxi-

mately 35 degrees the collar will be accessible.

(4) Loosen the two setscrews in the stop collar. (See

figures 8 and 12.) If, in preceding step (2), the

blade stopped with the acute angle greater than

45 degrees, rotate the stop collar counterclock-

wise (toward end of tilt screw). If the angle is

less than 45 degrees, rotate the collar clockwise

(away from end of tilt screw). For each trial

setting: move the stop collar a short distance

away from saw cradle (by rotating tilt hand-

wheel clockwise) loosen set screw, rotate the

stop collar a fraction of a turn in desired direc-

tion, tighten one of the set screws (figure 12)

and rotate the tilt hand-wheel counterclockwise

until it stops. Then measure the angle of saw

blade with table surface, as shown in figure 11.

\

I!_1 TILT

scREw

c. f

Figure 12

TABLE INSERT

Figure I3 _

Several trials will probc_bly be required to pro-

duce an accurate stop at the 45-degree position.

(5) Tighten one of the stop collar set screws securely

a{ter the adius_.ment has been completed.

NOTE: If the above adjustments have been

accurately performed, the saw will now have

a positive stop at "0" and "'45" degrees and

the pointer on tilt scale should stop at both

positions.

(6) Rotate the tilt hand-vcheel until it stops at the

"0'" position, as indicated by the pointer.

Adjust Table Insert as Follows:

a, Install the table inser,_ by" sliding it carefully into

position and pressing down firmly at both ends until

the spring clips on under'Side of insert "snap" into

position. (See figure 13.)

Loading ...

Loading ...

Loading ...