Loading ...

Loading ...

Loading ...

ore i o

motor specihcat ons and mounhng

(5) With saw blade all the way up, MAKE SURE IT

IS 90 ° OR SQUARE WITH THE TABLE.Raise the

blade guard and by using a square, adjust the

spl_r vertically 90° (Square) to the table.

Tighten the two5/16-18 x 1-inch screwsto secure

thesplitter blade bracket to the cradle. Place a

large square or straight-edge alongside the

saw blade. If the splitter is not in line with the

saw blade, loosenthe sockethead set screw(See

figure 36) and move the splitterassembly to the

right or left sothat it touches the square and is

in linewith the saw blade (See figure 37). Tighten

the set screw.

(6)

Recheckto make sure the following screws are

tight:

The socket-head set screw Cfigure 36) that se-

cures the splitter rod, and the two hex-head

screws (figure 371 that attach the splitter blade

bracket to saw cradle. Sight along splitter bar

and saw blade again after tightening these

screwsto make surealignment was not disturbed.

NOTE: After the splitter blade is properly

aligned, always remove the guard by loosen-

ing the thumb screw _figure 35) and sliding

the assembly off the splitter rod. This will

avoid upsetting any of the alignment adjust-

ments, as the pin in the splitter rod will serve

asa "stop" when the guard is installed.

CAUTION: When cleaning the plastic guard

isnecessary, wipe surfaces with a clean, dry

cloth. Do not use solvent of any kind.

MOTORSPECIFICATIONS& MOUNTING

1. This Craftsman Saw isdesigned for use with a 3450 rpm

motor. The saw arbor has a 2-1/2-1nch diameter pulley

_-_ attached and a 2-1/2-inch diameter motor pulley issup-

plied for driving the saw at the proper speed of 3450 rpm

through a 1 to 1 motor to saw ratio.

CAUTION: Do not install a larger diameter

pullev on the motor as it would drive the saw

blade at speeds which would be dangerous.

_,ivl The following Craftsman motors are recom-

./"/ 0 . .

?_ mended, available at any Sears Retad Store

J or Catalog Order House:

_¥E Catalog No. RPM Horsepower Vo|ts

/ - J_:_ _'_ _l

/ 99KT121 c3450 10120

99KT1220C 3450 1 110-120 or 230

/ t: _ fi_r wil°l!imt_fP_it aab_r_:t_ c_mmu::ddehdamn°_gteP"cl°t:s

/ _'_ / _ figuration that will not permit installation of the belt

/ _'_ i guard.

I Fiaureg 37 __l_

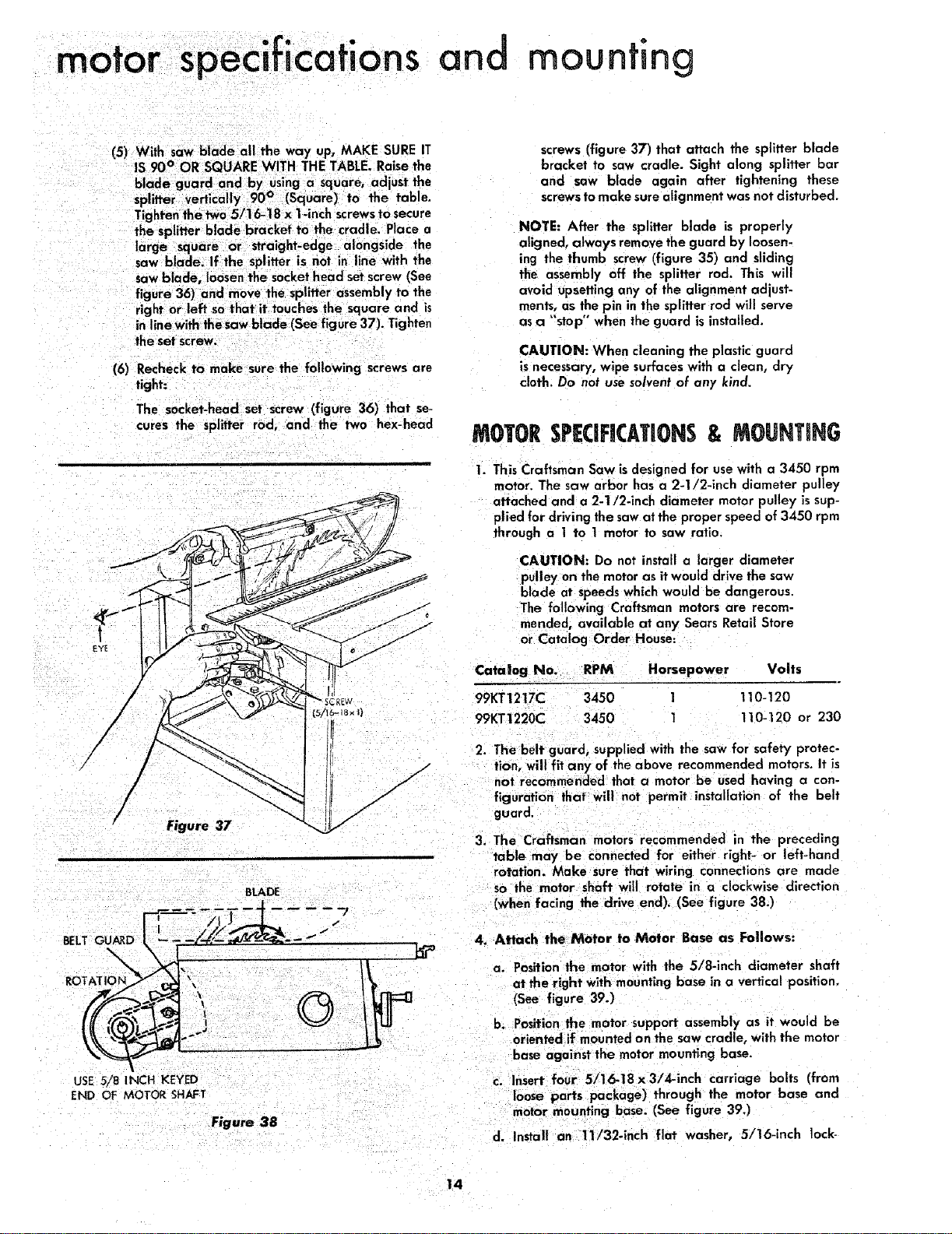

3. The Craftsman motors recommended in the preceding

table may be connected for either right- or left-hand

rotation. Make sure that wiring connections are made

so the motor shaft will rotate in a clockwise direction

BLADE

_7 (when facing the drive end). (See figure 38.)

BELT GUARD

use 5/B

END OF

\\

Figure 38

4. Attach the Motor to Motor Base as Follows:

a. Position the motor with the 5/8-inch diameter shaft

at the right with mounting base in a vertical position.

(See figure 39.)

b. Positionthe motor support assembly as it would be

oriented if mountedon the saw cradle, with the motor

base against the motor mounting base.

c. Insert four 5/16-18 x 3/4-inch carriage bolts (from

loose parts package) through the motor base and

motor mounting base. (See figure 39.)

d. Instal! an 11/32-inch flat washer, 5/164nch lock-

14

Loading ...

Loading ...

Loading ...