Loading ...

Loading ...

Loading ...

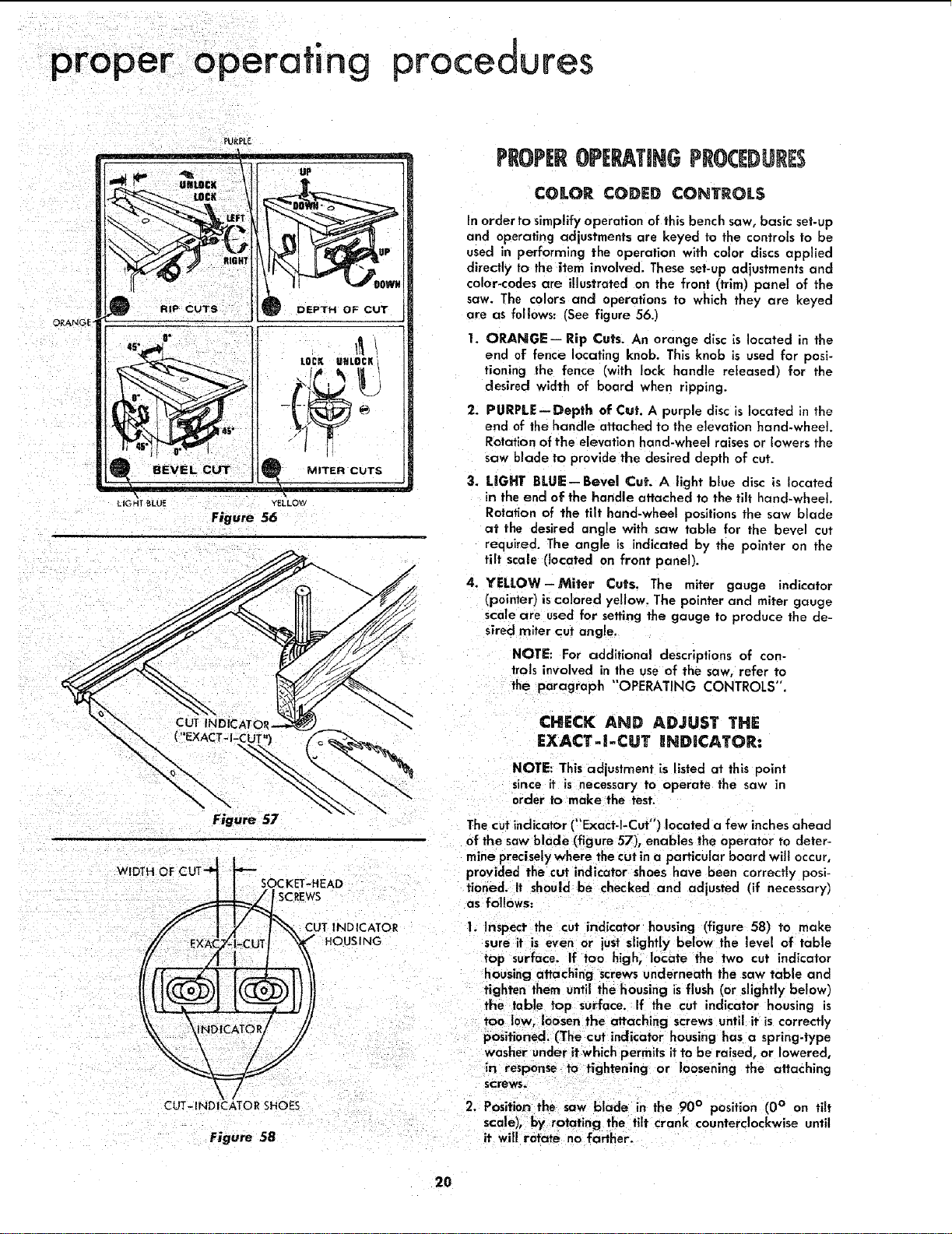

proper operating procedures

ORANG[

PUR_£

RIP CUTS DEPTH OF CUT

LOCK UflLOCK

MITER CUTS

tIGHT BLUE v'ELLOW

Figure 56

Figure 57

i,

WIDTH OF CUT-_

SOC KET-HEAD

rSCREWS

CUT INDICATOR

CUT-INDICATOR SHOES

Figure 58

P OPEROPEEATJNGPROCEDURES

COLOR CODED CONTROLS

In order to simplify operation of this bench saw, basic set-up

and operating adjustments are keyed to the controls to be

used in performing the operation with color discs applied

directly to the item involved. These set-up adjustments and

color-codes are illustrated on the front (trim) panel of the

saw. The colors and operations to which they are keyed

are as follows: (See figure 56.)

1. ORANGE-- Rip Cuts. An orange disc is located in the

end of fence locating knob. This knob is used for posi-

tioning the fence (with lock handle released) for the

desired width of board when ripping.

2. PURPLE--Depth of Cut. A purple disc is located in the

end of the handle attached to the elevation hand-wheel.

Rotation of the elevation hand-wheel raises or lowers the

saw blade to provide the desired depth of cut.

3. LIGHT BLUE--Bevel Cut. A light blue disc is located

in the end of the handle attached to the tilt hand-wheel.

Rotation of the tilt hand-wheel positions the saw blade

at the desired angle with saw table for the bevel cut

required, The angle is indicated by the pointer on the

tilt scale (located on front panel).

4. YELLOW-Miter Cuts. The miter gauge indicator

(pointer) is colored yellow. The pointer and miter gauge

scale are used for setting the gauge to produce the de-

sired -niter cut angle.

NOTE: For additional descriptions of con-

trois involved in the use of the saw, refer to

the paragraph "OPERATING CONTROLS".

CHECK AND ADJUST THE

EXACT-I-CUT gNDICATOR:

NOTE: This adjustment is listed at this point

since it is necessary TO operate the saw in

order to make the test.

The cut indicator ("Exact-I-Cut') located a few inchesahead

of the saw blade (figure 57), enables the operator to deter-

mine preciselywhere the cut in a particular board will occur,

provided the cut indicator shoes have been correctly posi-

tioned, it should be checked and adjusted (if necessary)

as follows:

1. Inspect the cut indicator housing (figure 58) to make

sure it is even or just slightly below the level of table

top surface. If too high, locate the two cut indicator

housing attaching screwsunderneath the saw table and

fig hten them until the housing is flush (or slightly below)

the table top surface. If the cut indicator housing is

too 10w, loosen the attaching screws until it is correctly

positioned. (The cut indicator housing has a spring.type

washer under it which permits it to be raised, or lowered,

in response to ffghtening or loosening the attaching

screws.

2. Position the saw blade in the 90 ° position (0 ° on tilt

scale), by rotating the tilt crank counterclockwise until

it will rotate no farther.

2O

Loading ...

Loading ...

Loading ...