Loading ...

Loading ...

Loading ...

safety instructions to operator

15. Make sure the top of the arbor or cuffing tool rotates

toward you when standing in normal operating position.

Also make sure the cutting tool, arbor collars and arbor

nut are installed properly. Keep the cutting tool as law

as possible for the operation being performed, Keep

all guards in place whenever possible.

]6, Do not useany blade or other cuffing tool marked for

an operating speed in excessof the designspeed of the

saw. Never use a cutting tool larger in diameter than

the diameter for which the saw was designed. For

greatest safety and efficiency when ripping, use the

maximum diameter blade for which the saw isdesigned,

since under these conditions the spreader is nearest

the blade,

]7. Adjust table inserts flush with, Or slightly below, the

table top.

18. For operations which do not permit the useof a spread-

er, seriousconsideration should be given to the use of

jigs or fixtures to hold the work so the hands of the op-

erator ore removed a safe distance from the point of

operation. (See the booklet "How To Do More _,Nith

Your Bench Saw.")

19. The use of abrasive or cut-off wheels, or wire wheels

can be dangerous and is not recommended. (Abrasive

or cut-off wheelsare used to saw many different ma-

terials including metals, stone, and glass.)

20. Objects can be thrown upward toward the operator by

the back of the blade if proper operating procedures

are not followed. This usually occurswhen a small loose

piece of wood or other object works around to the rear

of the revolving blade. It can usually be avoided by re-

moving all loose pieces from the table immediately

after they are cut off, using a long stick of wood, and

by keeping the guard and spreader in place at all times.

Use extra caution when the guard assembly is removed

for dadoing or molding, and replace the guard as soon

as that operation is completed.

21. Never perform any operation "freehand." This term

............ the stock into the saw blade or other

cutting tool without using the miter gauge, rip fence,

taper jig, or some other device which prevents rotating

or twisting of the workpiece during the operation.

22. Never turn your saw "ON" before clearing the table

of all objects (tools, scraps of wood, etc.) except the

workpiece and related feed or support devices for the

operation planned.

23. Safety is a combination of operator common senseand

alertness at all timeswhen the saw isbeing used.

24. Do not cycle the motor switchon and off rapidly, as this

may cause the saw blade to loosen. In the event this

should ever occur, allow the saw blade to come to a

complete step and retighten the arbar nut normally, not

excessively.

\!VARNENG: Do not allow familiarity

(gained from frequent use of your saw) to

became commonplace. Always remember

that a careless fraction of a second is suf-

ficient to inflict severe injury.

CONTENTS

Page Page

Unpacking and Pre-Assembly Instructions ... 5 Proper Operating Procedures . 20

Motor Specifications and Mounting ....... 14 Accessories ............... 25

Operating Controls .................... 19 Repair Parts ......................... 26

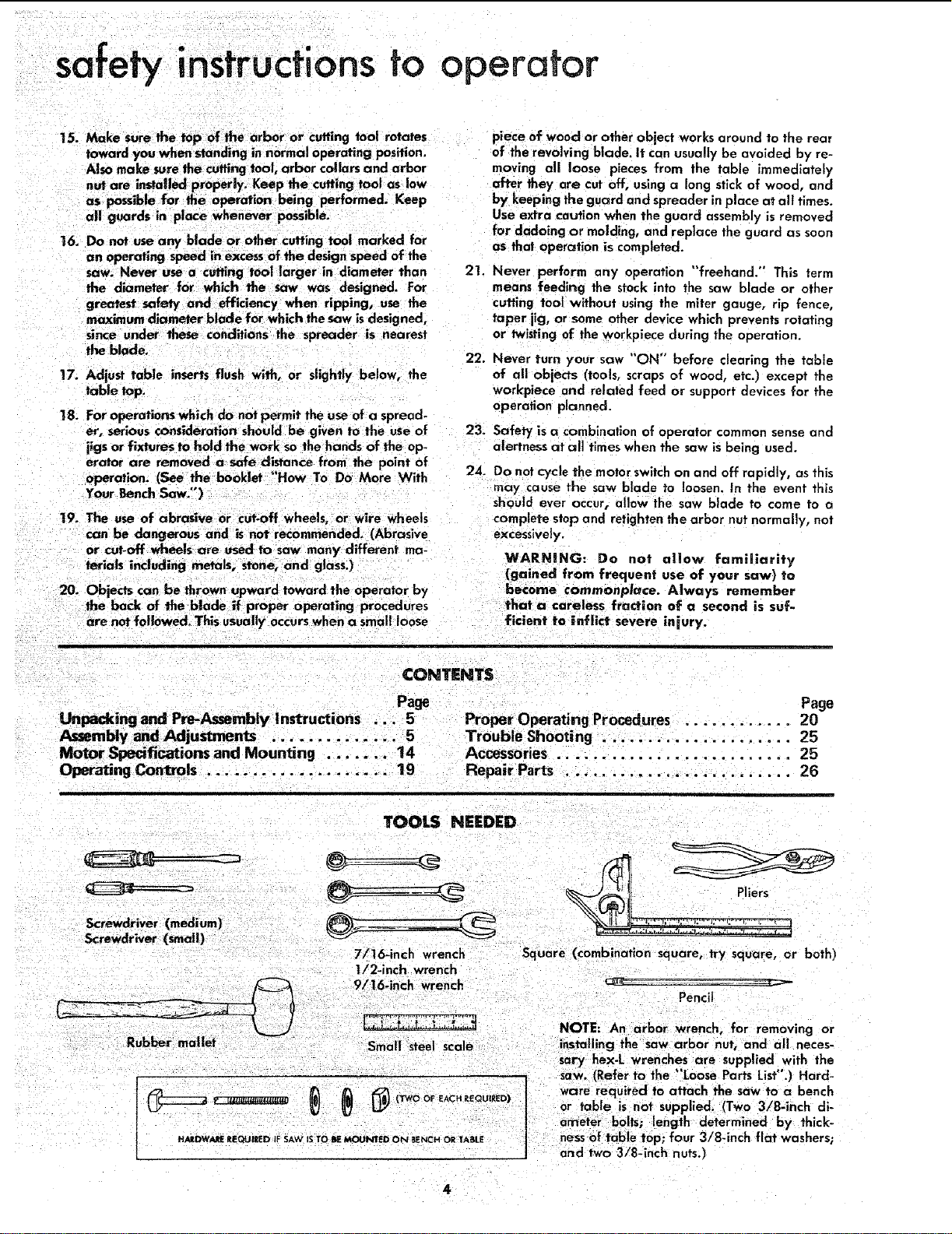

TOOLS NEEDED

Screwdriver (medium)

Screwdriver (small)

Rubber mallet

7/16-inch wrench

1/2-inch wrench

9/16.inch wrench

-_,,._ 4, ,_.r,-1. j-. ,,,

Small steel scale

v _ls_utu_ _ (TWO OF EACH I_EQUIEED)

HARDWARE RIEQUIEEO IF SAW IS TO lie MOUNTED ON BENCH OR TASBE

Square (combination square, try square, or both)

Pencil

ware required to attach the saw to a bench

or table is not supplied. (Two 3/8-inch di-

ameter bolls; length determined by thick-

nessof table top; four 3/8-inch flat washers;

arid two 3/8-inch nuts.l

Loading ...

Loading ...

Loading ...