Loading ...

Loading ...

Loading ...

and rnounfin

BELT GUARD

CLAMP RING

MOTOR POWER CORD

S

h.

driver./Cake sure the screw engages the openings in

the ring and rotate the screw until the clamp ring

diameter just leaves enough clearance on motor

frame for the guard to be slipped easily under the

ring.

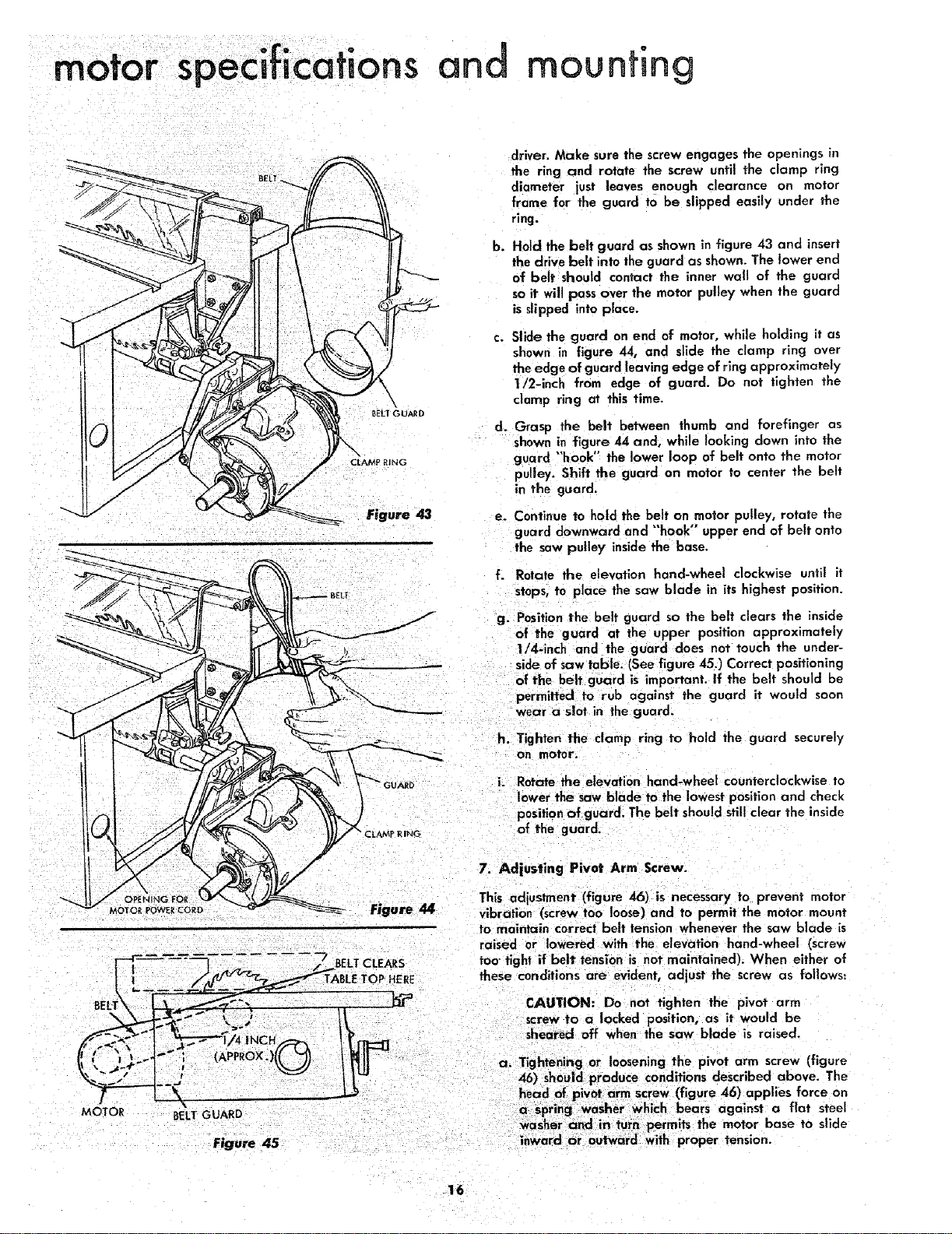

Hold the belt guard as shown in figure 43 and insert

the drive belt into the guard as shown. The lower end

of belt should contact the inner wall of the guard

so it will pass over the motor pulley when the guard

isslipped into place.

Slide the guard on end of motor, while holding it as

shown in figure 44, and slide the clamp ring over

the edge of guard leaving edge of ring approximately

1/2-inch from edge of guard. Do not tighten the

clamp ring at this time.

d. Grasp the belt between thumb and forefinger as

shown in figure 44 and, while looking down into the

guard "hook" the lower loop of belt onto the motor

pulley. Shift the guard on motor to center the belt

in the guard.

e. Continue to hold the belt on motor pulley, rotate the

guard downward and "'hook" upper end of belt onto

the saw pulley inside the base.

f. Rotate the elevation hand-wheel clockwise until it

stops,to place the saw blade in its highest position.

g. Positionthe belt guard so the belt clears the inside

of the guard at the upper position approximately

1/4-inch and the guard does not touch the under-

side of saw table. (See figure 45.) Correct positioning

of the belt guard is important. If the belt should be

permitted to rub against the guard it would soon

wear a s|ot in the guard.

h. Tighten the clamp ring to hold the guard securely

on motor.

i. Rotate the elevation hand-wheel counterclockwise to

lower the saw blade tothe lowest position and check

positionof guard, The beh should stillclear the inside

of the guard.

7. Adjusting Pivot Arm Screw.

This adjustment (figure 46) is necessary to prevent motor

vibration (screw too loose) and to permit the motor mount

to maintain correct belt tension whenever the saw blade is

raised or lowered with the elevation hand-wheel (screw

too" fight if belt tension is not maintained). When either of

these conditions are evident, adjust the screw as follows:

CAUTION: Do not tighten the pivot arm

screw to a locked position, as it would be

sheared off when the saw blade is raised.

a. Tightening or loosening the pivot arm screw (figure

MdTOR

Figure 45

16

Loading ...

Loading ...

Loading ...