Loading ...

Loading ...

Loading ...

adiustments

(4) Set the right-hand indicator (a scribed line in

the plastic window) to "'1" inch on the guide-bur

scale, This is accomplished as follows:

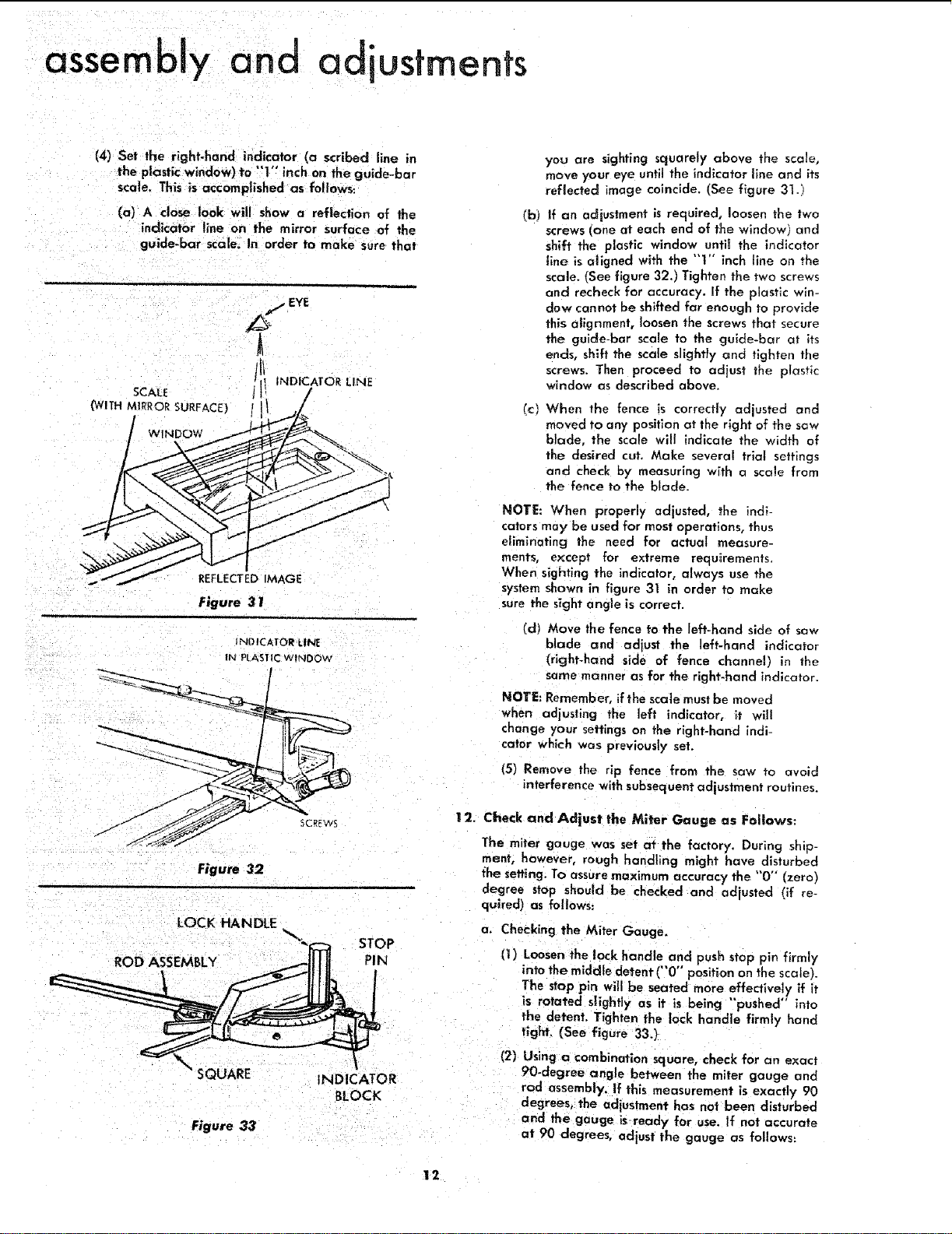

(a) A close look will show a reflection of the

indicator line on the mirror surface of the

guide-bar scale. In order to make sure that

SCALE

(WITH MIRROR SURFACE)

WINDOW

REFLECTEDIMAGE

Figure 31

IND ICATOR LINE

IN PLASTIC WINDOw

!

$CREWS

Figure 32

LOCK HANDLE

ROD ASSEMBLY

STOP

PIN

SQUARE

INDICATOR

BLOCK

Figure 33

yeu are sighting squarely above the scale,

move your eye until the indicator line and its

reflected image coincide. (See figure 31.1

(b) If an adiustrnent is required, loosen the two

screws cone at each end of the window] and

shift the plastic window untit the indicator

line is aligned with the "'!" inch line on the

scale, fSee figure 32.) Tighten the two screws

and recheck for accuracy. If the plastic win-

dow cannot be shifted far enough to provide

this alignment, loosen the screws that secure

the guide-bar scale to the gulde-bar at its

ends, shift the scale slightly and tighten the

screws. Then proceed to adjust the plastic

window as described above.

(c)

When the fence is correctly adjusted and

moved to any position at the right of the saw

blade, the scale will indicate the width of

the desired cut. Make several trial settings

and check by measuring with a scale from

the fence to the blade.

NOTE: When properly adjusted, the indi-

cators may be used for most operations, thus

eliminating the need for actual measure-

ments, except for extreme requirements.

When sighting the indicator, always use the

system shown in figure 31 in order to make

sure the sight angle is correct.

(d) Move the fence to the left-hand side of saw

blade and adjust the left-hand indicator

(right-hand side of fence channel) in the

same manner as for the right-hand indicator.

NOTE: Remember, if the scale must be moved

when adjusting the left indicator, it will

change your settings on the right-hand indi-

cator which was previously set.

(5) Remove the rip fence from the saw to avoid

interference with subsequent adjustment routines.

12. Check and Adjust the Miter Gauge as Follows:

The miter gauge was set at the factory. During ship-

ment, however, rough handling might have disturbed

the setting, To assure maximum accuracy the "0" (zero)

degree stop should be checked and adjusted (if re-

quired) as follows:

a, Checking the Miter Gauge.

(1) Loosen the lock handle and push stop pin firmly

into the middle detent ("0"" position on the scale).

The stop pin will be seated more effectively if it

is rotated slightly as it is being "pushed" into

the detent. Tighten the lock handle firmly hand

tight, (See figure 33,)

(2) Using a combination square, check for an exact

90-degree angle between the miter gauge and

rod assembly. If this measurement is exactly 90

degrees, the adjustment has not been disturbed

and the gauge is-ready for use. If not accurate

at 90 degrees, adjust the gauge as follows:

12

Loading ...

Loading ...

Loading ...