Loading ...

Loading ...

Loading ...

EN

15

Installation

www.bora.com

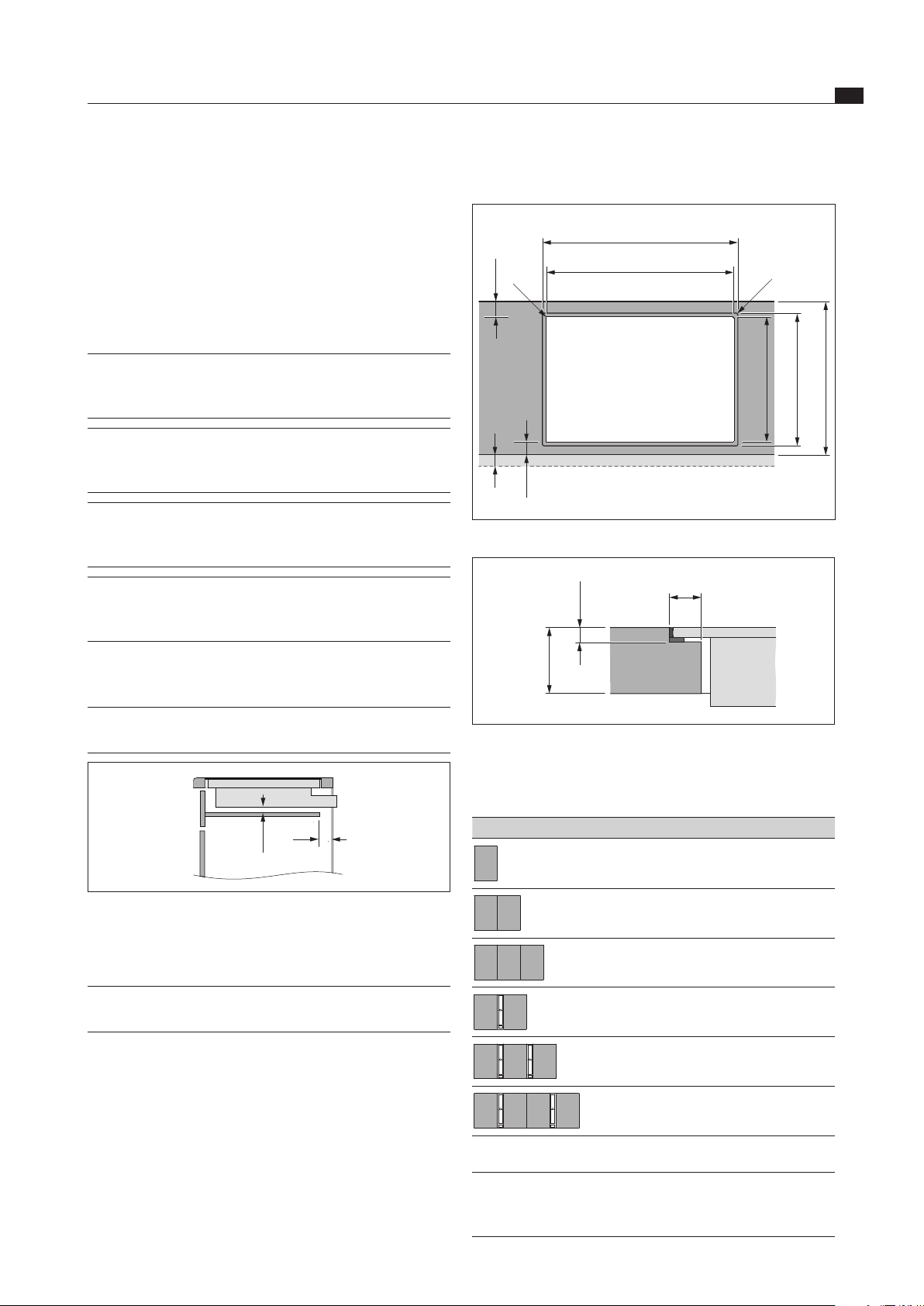

Flush installation

x

≥ 50

A ±2

B ±2

519 ±2

≤ R5

≤ R5

≥ 50

495 ±2

≥ 600

Fig. 6.3 Flush installation

5 +0,5

12

10 – 40

Fig. 6.4 Groove dimensions cut-out

Cut-out dimensions when installing cooktops only or cook-

tops and the BORA cooktop extractor alongside each other:

Cooktops/cooktop extractor A in mm B in mm

1/0 344 320

2/0 685 661

3/0 1026 1002

2/1 776 752

3/2 1208 1184

4/2 1549 1525

Tab. 6.2 Cut-out dimensions

INFO If the induction glass ceramic wok is used, the

groove dimensions must be increased to 7 mm

for flush installation.

A return flow aperture > 500 cm

2

is required in the

kitchen units for recirculation appliances (e.g. by

shortening the plinth boards or using suitable slatted

plinths).

6.3.3 Cooktop air intake

The components in the cooktop which generate heat are

automatically cooled. The warm air is extracted by fans

(cold air flow).

INFO In order to retain the full functionality of

the cooktop in the long term, there must be

sufficient ventilation underneath the cooktop.

INFO The performance of the cooktop is impaired or

the cooktop overheats if the warm air below

the cooktop cannot escape.

INFO If the cooktop overheats, performance

is reduced or the cooktop switches off

completely (see Overheating protection).

INFO For sufficient air intake, an opening cross-

section in the kitchen units of at least 50 cm

2

is recommended.

Ensure there is sufficient ventilation underneath the

cooktop.

INFO The cable protection (false floor) must not

prevent sufficient ventilation.

> 20

50

Fig. 6.2 Side view of the cable protection and ventilation

6.4 Cut-out dimensions

INFO All dimensions from the front edge of the

front cover.

Please note the worktop overhang x when creating

the worktop cut-out. Applies to flush installation and

surface mounting.

Loading ...

Loading ...

Loading ...