Loading ...

Loading ...

Loading ...

Adjustments for Wear

Bevel Lock

The purpose of the bevel lock is to lock the

motor at any bevel angle. An adjustment is

required if the motor can be easily moved by

hand when the bevel lock is locked or if bevel

lock offers minimal resistance when moving it

to the locked position. To make this adjust-

ment:

L Remove motor" support cover.

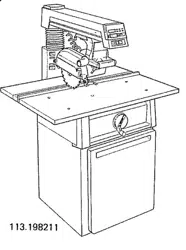

2oPosition the motor at approximately 30°

bevel angle and lock bevel lock_ (Figure 143)

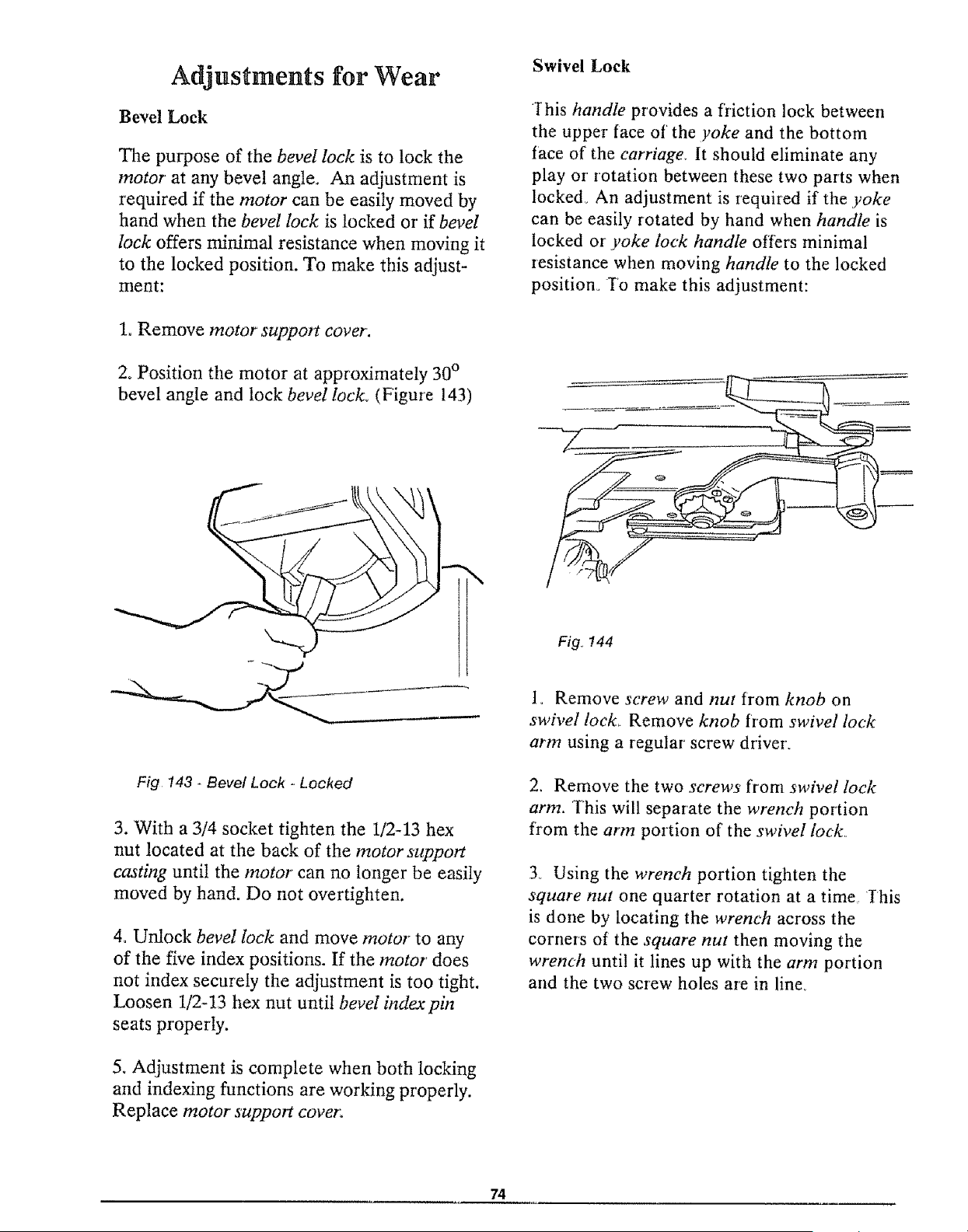

Swivel Lock

Ihis handle provides a fr'iction lock between

the upper face of the yoke and the bottom

t'ace of the carriage. It should eliminate any

play or' rotation between these two parts when

locked. An adjustment is required if the yoke

can be easily rotated by hand when handle is

locked or' ,yoke lock handle offers minimal

resistance when moving handle to the locked

position° To make this adjustment:

Fig. 144

Fig !43 * Bevel Lock - Locked

3. With a 3/4 socket tighten the 1/2-13 hex

nut located at the back of the motorsupport

casting until the motor can no longer be easily

moved by hand. Do not overtighten.

4, Unlock bevel lock and move motor to any

of the five index positions. If the motor does

not index securely the adjustment is too tight.

Loosen 1/2-13 hex nut until bevel indexpin

seats properly.

5oAdjustment is complete when both locking

and indexing functions are working properly.

Replace motor support cover:

1_ Remove screw and nut trom knob on

swivel lock_ Remove knob from swivel lock

arm using a regular screw driver.

2. Remove the two screws from swivel lock

arm. This will separate the wrench portion

from the arm portion of' the swivel lock

3_ Using the wrench portion tighten the

square nut one quarter rotation at a time,, Ihis

is done by locating the wrench across the

corners ot the square nut then moving the

wrench unti! it lines up with the arm portion

and the two screw holes are in line,,

74

Loading ...

Loading ...

Loading ...