Loading ...

Loading ...

Loading ...

14

GB

4. Installingtherefrigerantpiping

4.6. Additionalrefrigerantcharge

Additionalrefrigerantcharge

Refrigerant for the extended piping is not included in the outdoor unit when the unit is

shipped from the factory. Therefore, charge each refrigerant piping system with addi-

tional refrigerant at the installation site. In addition, in order to carry out service, enter

the size and length of each liquid pipe and additional refrigerant charge amounts in

the spaces provided on the “Refrigerant amount” plate on the outdoor unit.

Calculationofadditionalrefrigerantcharge

• Calculate the additional charge using the liquid pipe size and length of the ex-

tended piping.

• Calculate the additional refrigerant charge using the procedure shown to the

right, and charge with the additional refrigerant.

• For amounts less than 0.1kg,roundup the calculated additional refrigerant

charge.

(For example, if the calculated charge is 32.92 kg, round up the charge to 33.0

kg.)

<AdditionalCharge>

Calculationofrefrigerantcharge

Pipe size

Liquid pipe

+

Pipe size

Liquid pipe

+

Total capacity of

connected indoor units

Amount for the

indoor units

ø6.35 ø9.52 ~ 8.0 kW 1.5 kg

(m) ×19.0(g/m) (m) ×50.0(g/m) 8.1 ~ 16.0 kW 2.5 kg

16.1 ~ 20.4 kW 3.0 kg

Includedrefrigerantamountwhenshippedfromthefactory

Included refrigerant amount

3.5 kg

Calculationexample(PleaseseethelowerhalfofFig.4-1.)

Outdoormodel:SP140 A:ø9.52[3/8"]/ø

15.88

[

5/8"

]:30m

1: P100 (11.2 kW)

a:ø9.52[3/8"]/ø15.88[5/8"]

:

15 m

2: P40 (4.5 kW)

b:ø6.35[1/4"]/ø12.7[1/2"]

:

10 m

The total length of each pipe size is as follows:

ø9.52

[3/8

"

]/

ø

15.88

[

5/8"

]:A=30m

ø9.52

[3/8

"

]/

ø15.88

[5/8"]

: a = 15 m

ø6.35

[1/4

"

]/

ø12.7

[1/2

"

]

: b = 10 m

The total capacity of connected indoor unit is as follows:

11.2 + 4.5 = 15.7

Therefore, the additional charge is as follows:

= 10 ×

19.0

+ (30 + 15) ×

50.0

+ 2.5

1000 1000

= 5.0 kg

For these

piping

lengths

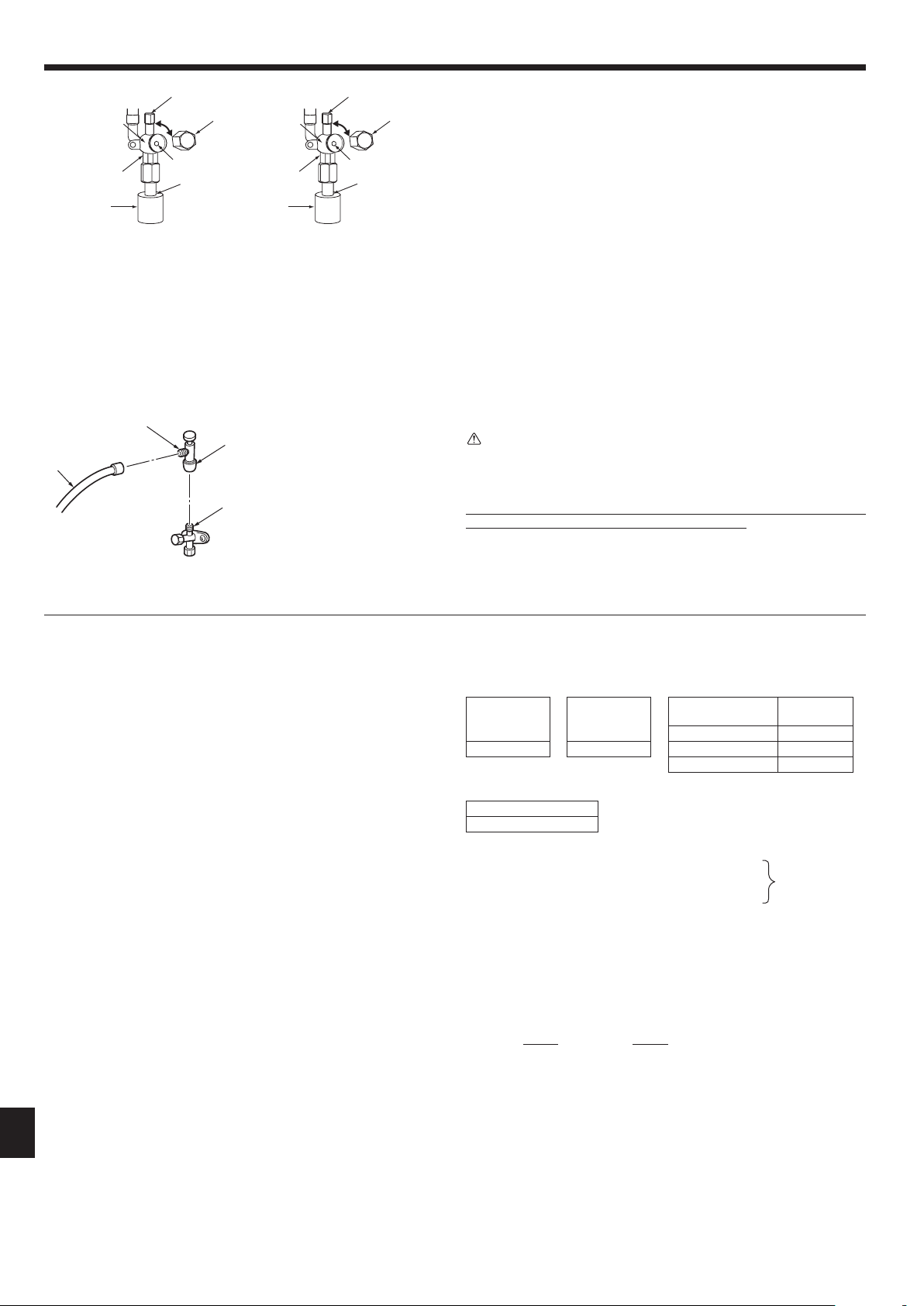

4.5.Stopvalveopeningmethod

Thestopvalveopeningmethodvariesaccordingtotheoutdoorunitmodel.Usethe

appropriate method to open the stop valves.

(1) Gas side (Fig. 4-12)

1 Remove the cap and turn the valve rod counterclockwise as far as it will go with

the use of a 5 mm hexagonal wrench. Stop turning when it hits the stopper.

(ø15.88:Approximately13revolutions)

2 Make sure that the stop valve is open completely and rotate the cap back to its

original position.

(2) Liquid side (Fig. 4-13)

1 Remove the cap and turn the valve rod counterclockwise as far as it will go with

the use of a 4 mm hexagonal wrench. Stop turning when it hits the stopper.

(ø9.52:Approximately10revolutions)

2 Make sure that the stop valve is open completely, push in the handle and rotate

the cap back to its original position.

Refrigerant pipes are protectively wrapped

• Thepipescanbeprotectivelywrappeduptoadiameterofø90beforeoraftercon-

necting the pipes. Cut out the knockout in the pipe cover following the groove and

wrap the pipes.

Pipe inlet gap

• Useputtyorsealanttosealthepipeinletaroundthepipessothatnogapsremain.

(If the gaps are not closed, noise may be emitted or water and dust will enter the

unit and breakdown may result.)

Warning:

Wheninstallingtheunit,securelyconnecttherefrigerantpipesbeforestarting

thecompressor.

Precautionswhenusingthechargevalve(Fig.4-14)

Do not tighten the service port too much when installing it, otherwise, the valve core

could be deformed and become loose, causing a gas leak.

After positioning section B in the desired direction, turn section A only and tighten it.

Do not further tighten sections A and B together after tightening section A.

B

C

A

D

* The gure to the left is an example

only. The stop valve shape, service port

position, etc., may vary according to the

model.

* Turn section A only.

(Do not further tighten sections A and

B together.)

C Charge hose

D Service port

Fig.4-14

Fig.4-12 Fig.4-13

H Double spanner section

(Do not apply a spanner other than to this section. Doing

so would cause coolant leaks.)

I Seal section

(Seal the end of the heat insulation material at the pipe

connection section with whatever seal material you

haveonhandsothatwaterdoesnotinltratetheheat

insulation material.)

A Valve

B Unitside

C Cap

D Local pipe side

E Pipe cover

F Service port

G Wrench hole

(1) (2)

H H

E E

F F

A A

G G

I I

D D

C C

B B

RG79Y960H01.indb 14 2018/02/09 14:31:08

Loading ...

Loading ...

Loading ...