Loading ...

Loading ...

Loading ...

12

GB

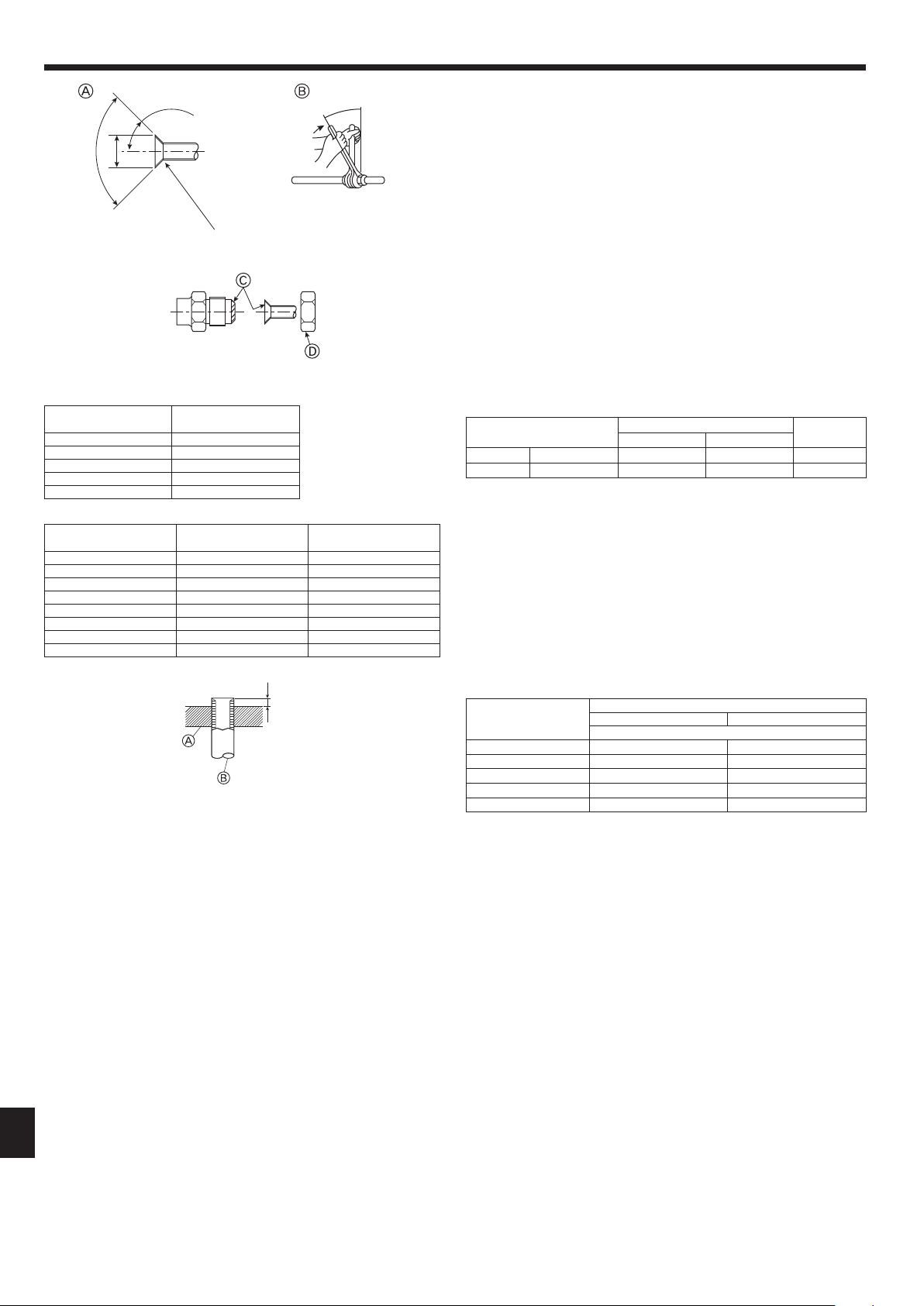

A Flare cutting dimensions

B Flare nut tightening torque

A Die

B Copper pipe

Fig.4-8

A

Fig.4-9

A (Fig. 4-8)

B (Fig. 4-8)

90°± 0.5°

øA

45°± 2°

R0.4 - R0.8

Copper pipe O.D.

(mm)

Flare dimensions

øAdimensions(mm)

ø6.35 8.7 - 9.1

ø9.52 12.8 - 13.2

ø12.7 16.2 - 16.6

ø15.88 19.3 - 19.7

ø19.05 23.6 - 24.0

Copper pipe O.D.

(mm)

Flare nut O.D.

(mm)

Tightening torque

(N·m)

ø6.35 17 14 - 18

ø6.35 22 34 - 42

ø9.52 22 34 - 42

ø12.7 26 49 - 61

ø12.7 29 68 - 82

ø15.88 29 68 - 82

ø15.88 36 100 - 120

ø19.05 36 100 - 120

4.2. Connectingpipes(Fig.4-8)

Fig. 4-1, 4-2 is a sample of piping system.

• Conductsufcientanti-condensationandinsulationworktopreventwaterdripping

fromtherefrigerantpiping.(liquidpipe/gaspipe)

• Increase insulation depending on the environment where the refrigerant piping

is installed, or condensation may occur on the surface of the insulation material.

(Insulation material Heat-resistant temperature: 120 °C, Thickness: 15 mm or more)

* When the refrigerant piping is used in locations subject to high temperature and

humidity such as in the attic, further addition of insulation may be required.

• Toinsulatetherefrigerantpiping,applyheat-resistantpolyethylenefoambetween

the indoor unit and insulation material as well as to the net between the insulation

materialllingallgaps.

(Condensation forming on the piping may result in condensation in the room or

burns when contacting the piping.)

• Besuretoseparatethermalinsulationforgasandliquidrefrigerantpipes.

• Theindoorpartsofthedrainpipeshouldbewrappedwithpolyethylenefoaminsula-

tionmaterials(specicgravityof0.03,thicknessof9mmormore).

• Applythinlayerofrefrigerantoiltopipeandjointseatingsurfacebeforetightening

arenut.A

• Use2wrenchestotightenpipingconnections.B

• Use leak detector or soapy water to check for gas leaks after connections are

completed.

• Applyrefrigeratingmachineoilovertheentireareseatsurface.C

• Usethearenutsforthefollowingpipesize.D

City Multi Indoor unit

Outdoor unit

15-50 63-140

Gas side Pipe size (mm) ø12.7 ø15.88 ø15.88

Liquid side Pipe size (mm) ø6.35*1 ø9.52 ø9.52

*1 Ifthefarthestpipinglengthaftertherstjointexceeds30m,useapipesizeofø9.52.

• When bending the pipes, be careful not to break them. Bend radius of 100 mm to

150mmissufcient.

• Make sure the pipes do not contact the compressor. Abnormal noise or vibration

may result.

1 Pipes must be connected starting from the indoor unit.

Flare nuts must be tightened with a torque wrench.

2 Flare the liquid pipes and gas pipes and apply a thin layer of refrigeration oil (Ap-

plied on site).

• Whenusualpipesealingisused,refertoTable3foraringofR410Arefrigerant

pipes.

ThesizeadjustmentgaugecanbeusedtoconrmAmeasurements.

* Toconnectthe CONNECTIONKIT(PAC-LV11M-J),refertotheinstallation

manualfortheCONNECTIONKIT.

Table 3 (Fig. 4-9)

Copper pipe O.D.

(mm)

A (mm)

Flare tool for R410A Flare tool for R22·R407C

Clutch type

ø6.35(1/4") 0 - 0.5 1.0 - 1.5

ø9.52(3/8") 0 - 0.5 1.0 - 1.5

ø12.7(1/2") 0 - 0.5 1.0 - 1.5

ø15.88(5/8") 0 - 0.5 1.0 - 1.5

ø19.05(3/4") 0 - 0.5 1.0 - 1.5

4. Installingtherefrigerantpiping

RG79Y960H01.indb 12 2018/02/09 14:31:06

Loading ...

Loading ...

Loading ...