Loading ...

Loading ...

Loading ...

43INSTALLING THE FREESTANDING COOKER42 WIRING REQUIREMENTS

WIRING REQUIREMENTS

The cooker MUST be installed in compliance with:

• wiring connections in AS/NZS 3000 Wiring Rules.

• local regulations, municipal building codes and

other statutory regulations.

For New Zealand Only:

The cooking range must be connected to the supply by

a supply cord fitted with the appropriately rated plug

that is compatible with the socket-outlet fitted to the

final sub-circuit in the fixed wiring that is intended to

supply this cooking range.

Supply cord size required:

WFE914SB/WVE914SB/WVE916SB - 1.5mm

2

WFEP915SB/WVEP916SB - 4.0mm

2

WFE946SB - 6.0mm

2

The Data plate gives information about rating and is

located behind the bottom of the oven door.

• A functional switch MUST be provided near the

appliance in an accessible position (AS/NZS 3000

- Clause 4.7.1).

• Wiring MUST be protected against mechanical

failure (AS/NZS 3000 - Clause 3.9).

• Disconnection in the fixed wiring must occur in

accordance with the AS/NZS3000 wiring rules.

• The cooker MUST be properly earthed.

• This range must be connected with cable of 75°C

rating minimum.

• This product has passed the insulation resistance

test after manufacture. If the resistance reading

is low at installation, it is probably caused by

moisture from the atmosphere being absorbed by

the elements after the range has been produced.

(pass at 0.01 M

AS/NZS 3000 Wiring Rules Clause

8.3.6.2).

Note: When connections are made to a multi-phase

230/240V supply, the bridge piece MUST be removed

from between the active connections.

Rated power input

MODEL TOTAL KW A1 KW A2 KW

WFE946 13.1 3.6 9.5

TIPS & INFORMATION

IMPORTANT

Before you cook in your new oven it is important that

the protective oils used in the manufacture of the

product be removed.

• Make sure that the room is well ventilated (to allow

smoke to escape).

• Run the grill on high for 30 minutes without grill dish.

• Then run the oven on 180°C for 1 hour.

Connecting to services and commissioning

This appliance must be installed by an authorised

person, according to all codes and regulations of:

• Electrical supply authorities.

• Building regulations.

• Local government and council authorities.

• AS/NZS5601.1(particular attention to 6.10.1 and

figure 6.3, and clause 6.10.1.11).

• AS/NZS 3000 (particular attention to clause 4.3.11

and clause 3.9).

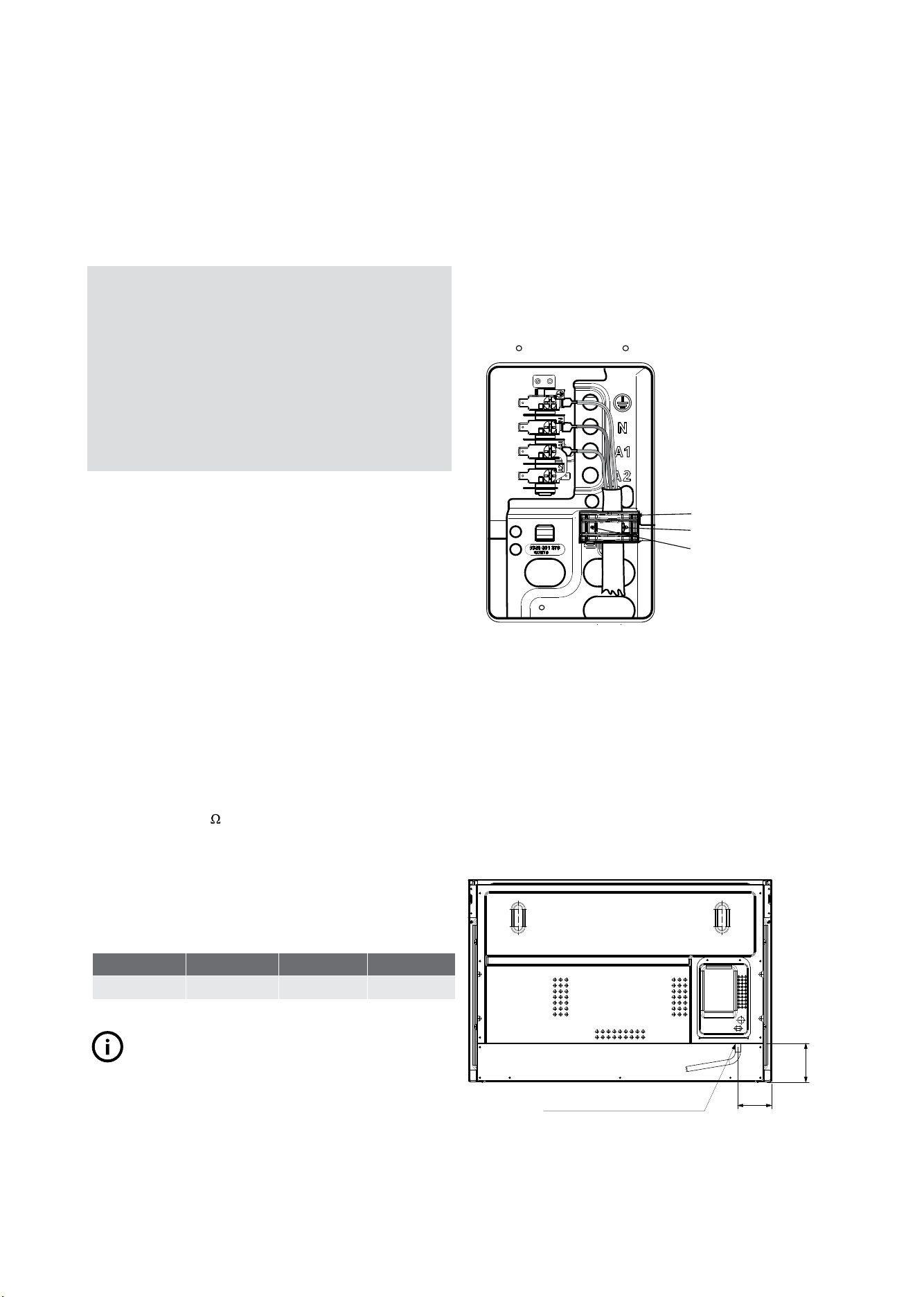

Securing points

Plastic clips

Plastic clip

Hard wiring detail

1. Remove terminal cover plate from rear panel of

appliance.

2. Fit wires through hole in cover plate and make

connections to terminals.

3. Engage wires into plastic clip. Secure plastic clip

with two long silver screws (supplied in separate

bag).

4. Replace cover plate onto rear panel.

Electrical connection location - built-in models

Entry point of electrical cable

99

113

INSTALLING THE FREESTANDING COOKER

Gas connection

Read these points before connecting to the gas supply:

• The appliance is preset for natural gas use, if LPG is

to be used see Conversion to LPG section.

• Gas installation must be made in accordance with AS/

NZS5601.1, the local gas fitting regulations, municipal

codes and other statutory regulations.

• The gas connection point is a ½” BSP external thread

located at the rear of the appliance as shown.

• The regulator is to be fitted to the manifold inlet at

the rear of the appliance and the connectionis sealed

using a tape or jointing compound suitable for gas

connections. The consumer piping is then connected to

the inlet of the regulator, either

1. directly, or

2. using a hose assembly and in accordance

with Clause 6.10.1.9 of AS 560101 (High level

connection) together with the supplied elbow.

The elbow is fitted to the inlet of the regulator

and oriented to allow the hose to hang

downward. The connection thread between the

regulator and elbow is sealed using a tape or

jointing compound suitable for gas connections.

Models WFE914SB, WFEP915SB AND WFE946SB

168

95

Electrical connection cable

806

411

Gas connection point to regulator

Models: WFE914SB, WFEP915SB

Electrical cable

entry point

Models: WFE914SB,

WFEP915SB,

WFE946SB

Gas pressures

The following table shows the supply and operating

pressures for various gases.

GAS TYPE

NATURAL

GAS

UNIVERSAL

LPG

Supply pressure at inlet

to appliance regulator

(if fitted)

1.13 (kPa)

Minimum

2.75*

(kPa)

Operating pressure at

appliance test point

1.00 (kPa) 2.6 (kPa)

*If the regulator is placed upstream of the cooker inlet, as is normal

for cookers operating on LPG, then the supply pressure and

operating pressure are the same.

The following table shows the injector sizes for

each burner.

INJECTOR ORIFICE

NATURAL

GAS

UNIVERSAL

LPG

Low heat burner 1.00mm 0.55mm

Medium heat burner 1.35mm 0.70mm

High heat burner 1.60mm 0.90mm

Intense heat wok

burner

1.75mm 1.00mm

Checking piping size

To work out a suitable pipe size for connection use the

information in this table.

GAS TYPE NATURAL

GAS

UNIVERSAL

LPG

WFE914 & WFEP915 49.6 MJ/h 40.9 MJ/h

For information and requirements about construction and

capacity of consumer piping refer to AS5601 series of

standards.

Loading ...

Loading ...

Loading ...