Loading ...

Loading ...

Loading ...

18 INSTALLATION

Routing and Connecting Ductwork

NOTE

Follow the guidelines below to maximize drying

performance and reduce lint buildup and

condensation in the ductwork. Ductwork and

ttings are NOT included and must be purchased

separately.

• Use 4-inch (10.2 cm) diameter rigid, semi-rigid or

exible metal ductwork.

• The exhaust duct run should be as short as

possible.

• Use as few elbow joints as possible.

• The male end of each section of exhaust duct must

point away from the dryer.

• Use duct tape on all duct joints.

• Insulate ductwork that runs through unheated areas

in order to reduce condensation and lint buildup on

duct surfaces.

• Incorrect or inadequate exhaust systems are not

covered by the dryer warranty. Dryer failures or

service required because of such exhaust systems

will not be covered by the dryer warranty.

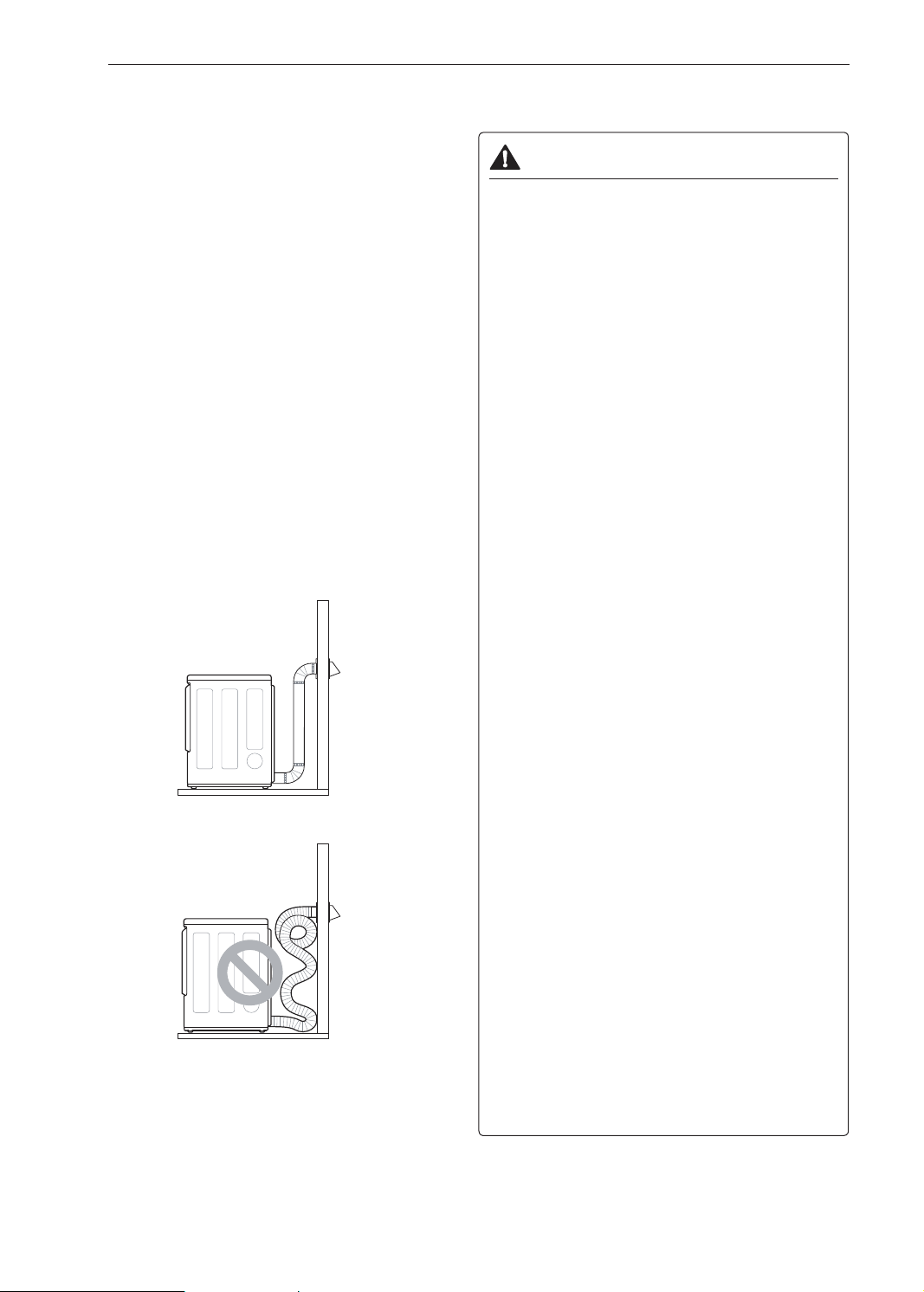

Correct Venting

Incorrect Venting

Connecting Gas Dryers

WARNING

To reduce the risk of re or explosion, electric

shock, property damage, injury to persons,

or death when using this appliance, follow

requirements including the following:

Electrical Requirements for Gas

Models Only

• Do not, under any circumstances, cut or remove

the third (ground) prong from the power cord.

• For personal safety, this dryer must be properly

grounded.

• This dryer must be plugged into a 120-VAC,

60-Hz. grounded outlet protected by a

15-ampere fuse or circuit breaker.

• Where a standard 2-prong wall outlet is

encountered, it is your personal responsibility

and obligation to have it replaced with a properly

grounded 3-prong wall outlet.

ELECTRIC SHOCK HAZARD

Failure to follow safety warnings could result

in serious injury

• This dryer is equipped with a three-prong

grounding plug for protection against shock

hazard and should be plugged directly into a

properly grounded three-prong receptacle. Do

not cut or remove the grounding prong from this

plug.

Gas Supply Requirements

• As shipped from the factory, this dryer is

congured for use with natural gas (NG). It can

be converted for use with propane (LP) gas.

Gas pressure must not exceed 8-inch (20.4 cm)

water column for NG, or 13-inch (33.1 cm) water

column for LP.

• A qualied service or gas company technician

must connect the dryer to the gas service.

• Isolate the dryer from the gas supply system by

closing its individual manual shutoff valve during

any pressure testing of the gas supply.

• DO NOT attempt any disassembly of the dryer;

disassembly requires the attention and tools of

an authorized and qualied service technician or

company.

• Securely tighten all gas connections.

• Connect the dryer to the type of gas shown on

the nameplate.

Loading ...

Loading ...

Loading ...