Loading ...

Loading ...

Loading ...

32

SERVICE AND MAINTENANCE

Battery Failures

Some common causes for battery failure are:

• Incorrect initial activation

• Overcharging

• Freezing

• Undercharging

• Corroded connections

These failures are NOT covered by your tractor’s warranty.

Jump Starting

WARNING

Never jump start a damaged or frozen battery. Be certain the vehicles

do not touch, and ignitions are off. Do not allow cable clamps to

touch.

1. Connect positive (+) cable to positive post (+) of your tractor’s discharged

battery.

2. Connect the other end of the cable to the positive (+) post of the jumper

battery.

3. Connect the second cable negative (–) to the negative post (–) of the jumper

battery.

4. Connect the other end of the negative cable to the engine block of the

tractor, away from the battery. Attach to an unpainted part to assure a good

connection.

WARNING

If the jumper battery is installed on a vehicle (i.e. car, truck), do NOT start

the vehicle’s engine when jump starting your tractor.

5. Start the tractor (as instructed in the Operation section of this manual).

6. Set the tractor’s parking brake before removing the jumper cables, in reverse

order of connection.

Charging

WARNING

Batteries give off an explosive gas while charging. Charge the battery in

a well ventilated area and keep away from an open flame or pilot light

as on a water heater, space heater, furnace, clothes dryer or other gas

appliances.

CAUTION

When charging your tractor’s battery, use only a charger designed for 12V

lead-acid batteries. Read your battery charger’s Owner’s Manual prior to

charging your tractor’s battery. Always follow its instructions and heed its

warnings.

If your tractor has not been put into use for an extended period of time, charge the

battery as follows:

1. Set your battery charger to deliver a max of 10 amperes.

If your battery charger is automatic, charge the battery until the charger indicates

that charging is complete. If the charger is not automatic, charge for no fewer than

eight hours.

Fuse

One 15 AMP fuse is installed in your tractor’s wiring harness to protect the tractor’s

electrical system from damage caused by excessive amperage.

If the electrical system does not function, or your tractor’s engine will not crank;

first check to be certain that the fuse has not blown. It can be found under the

fender on the left side of the unit, on the wiring harness just above the battery.

WARNING

Always use a fuse with the same amperage capacity for replacement.

Lubrication

WARNING

Before lubricating, repairing, or inspecting, always disengage PTO (Blade

Engage Lever), move shift lever into neutral position, set parking brake, stop

engine and remove key to prevent unintended starting.

Pivot Points & Linkage

Lubricate all the pivot points on the drive system, parking brake and lift linkage at

least once a season with light oil.

Rear Wheels

The rear wheels should be removed from the axles once a season. Lubricate the

axles and the rims well with an all-purpose grease before re-installing them.

Front Axles

Each end of the tractor’s front pivot bar may be equipped with a grease fitting.

Lubricate with a grease gun after every 25 hours of tractor operation.

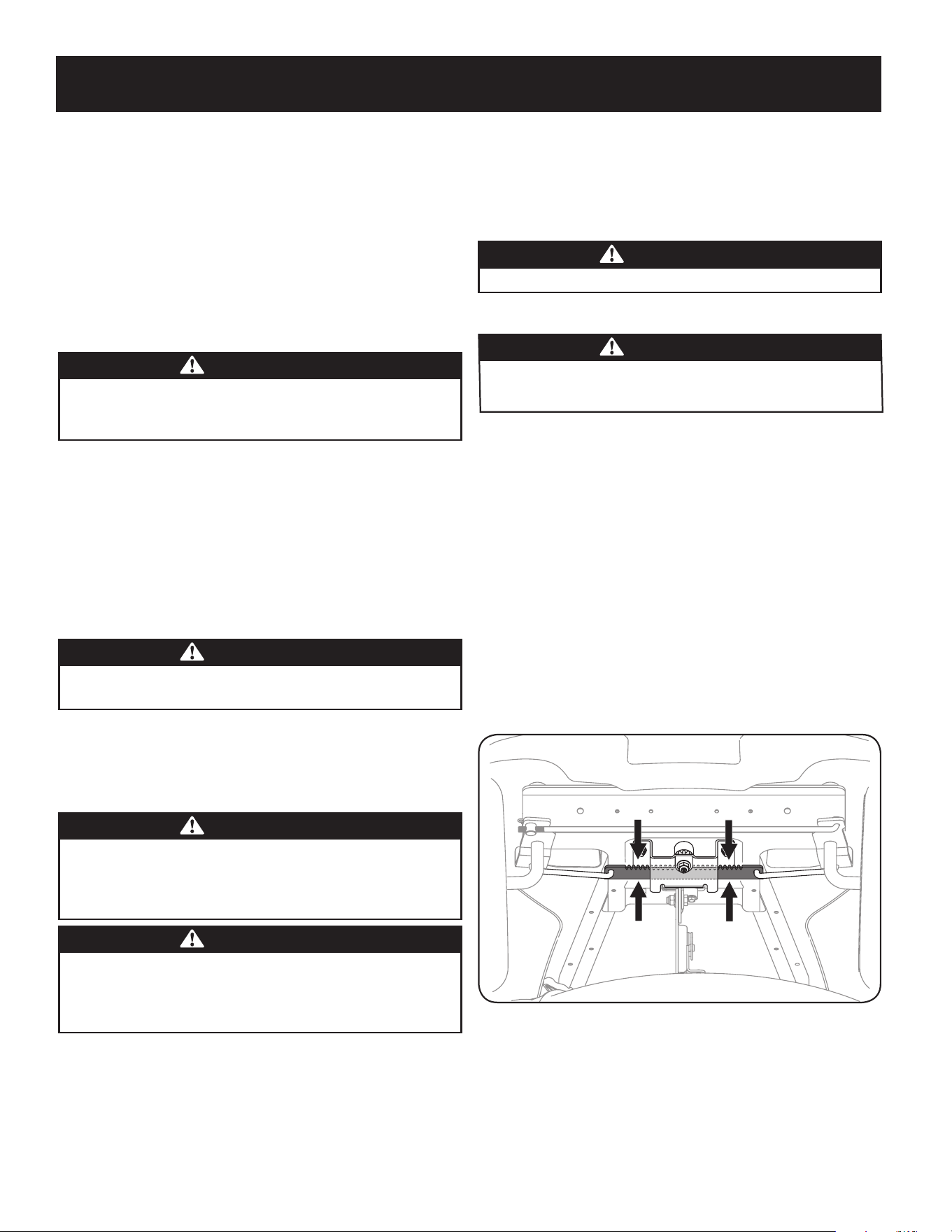

Steering Rack & Pinion

Once per season, or every 25 hours of operation, it will be necessary to lubricate the

steering rack and pinion gear located under the front of the unit. Using standard

automotive grease, apply grease to the front side and rear side of the steering rack,

as indicated in “Figure 25”.

Figure 25

Loading ...

Loading ...

Loading ...