Loading ...

Loading ...

Loading ...

23

SERVICE AND MAINTENANCE

Storing the Rider

• Allow the machine to cool in an open area before storing.

• Do not park the rider near any flammable materials (wood, cloth or

chemicals) or any open flames or other potential source of ignition (furnace,

water heater or any other type of heater).

• Remove all combustible materials from the rider before storing. Empty cargo

boxes, grass catchers or containers.

• Always shut off fuel flow when storing or transporting if rider is equipped

with a fuel shutoff.

• Check the fuel system (lines, tank, cap and fittings) frequently for cracks or

leaks. Repair and clean as necessary.

Engine Maintenance

WARNING

Shut off the engine before performing any maintenance. To prevent

accidental start-up, disconnect the spark plug boot.

IMPORTANT: If engine must be tipped to transport equipment or to inspect or

remove grass, keep spark plug side of engine up. Transporting or tipping engine

spark plug down may cause smoking, hard starting, spark plug fouling, or oil

saturation of air cleaner.

Periodic inspection and adjustment of the engine is essential if high level

performance is to be maintained. Regular maintenance will also ensure a long

service life. The required service intervals and the kind of maintenance to be

performed are described in the table on the previous page. Follow the hourly or

calendar intervals, whichever occur first. More frequent service is required when

operating in adverse conditions.

WARNING

If the engine has been running, the muffler will be very hot. Be careful not

to touch the muffler.

Servicing the Engine Oil

• Check the oil level regularly.

• Be sure correct oil level is maintained. Check the oil every five to ten hours of

operation, before starting the engine. See Checking Oil Level in the Assembly section.

Only use high quality detergent oil rated with API service classification SF, SG,

SH, or SJ. Select the oil’s SAE viscosity grade according to the expected operating

temperature. Refer to Gas & Oil in the Assembly section of this manual.

Oil Drain

IMPORTANT: Be sure to check engine on a level surface with the engine stopped.

Drain the oil while the engine is still warm to assure rapid and complete draining.

For draining oil from the engine’s crankcase of select model tractors, a plastic oil drain

sleeve is packed with this Operator’s Manual. To drain the oil, proceed as follows:

13. Unscrew the oil fill cap and remove the dipstick from the oil fill tube.

14. Snap the small end of oil drain sleeve onto the oil sump. See “Figure 4”.

15. Remove drain plug and drain oil into a suitable container with a capacity of

no less than 64 oz.

16. Tip the tractor slightly in the direction of the suitable container to aid in fully

draining all of the oil from the engine.

WARNING

Before tipping engine or equipment to drain oil, drain fuel from tank by

running engine until fuel tank is empty.

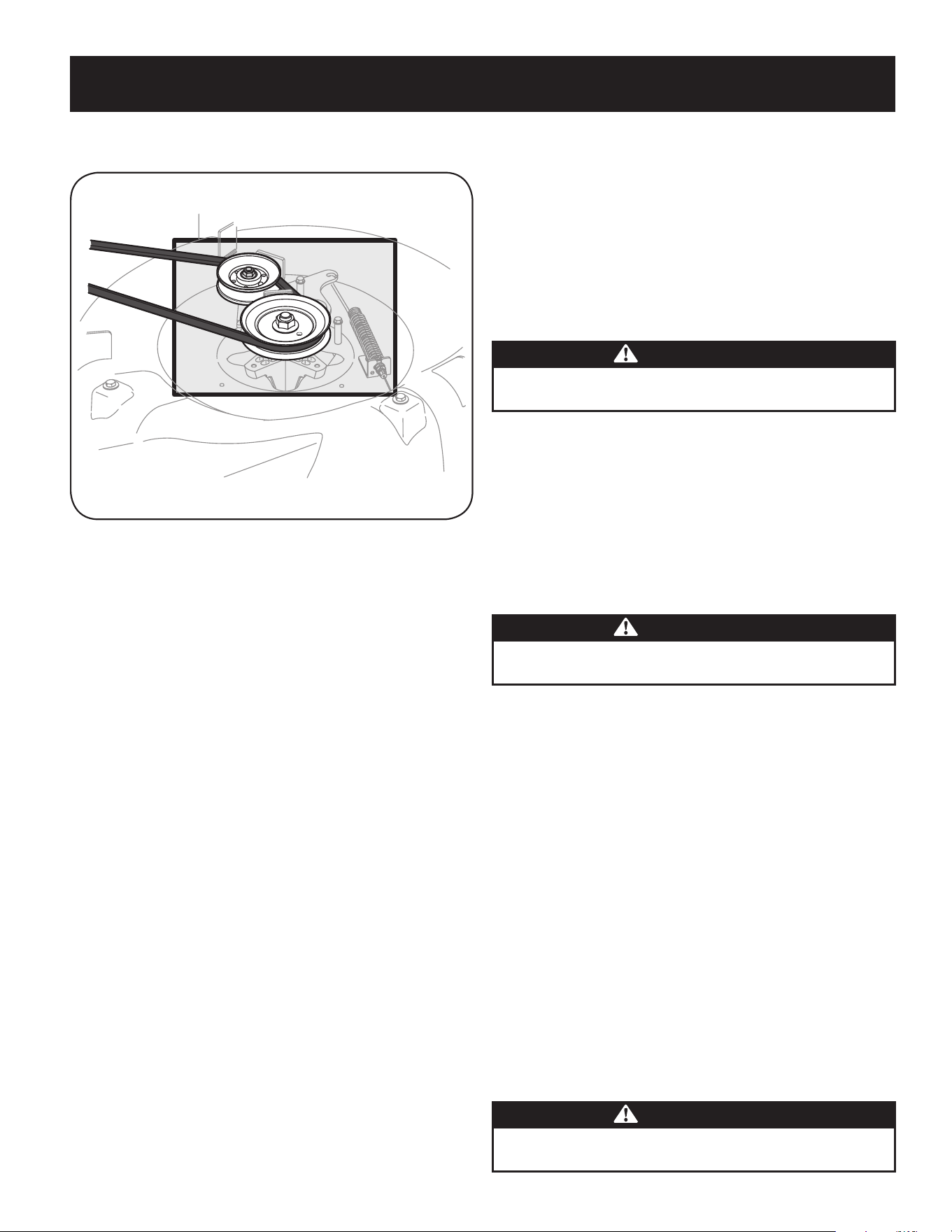

• Clean the top of the mower deck, under the spindle covers and belt area. See

“Figure 3”.

Figure 3

• Clean around and near the transmission, axle and the fan area. See “Figure

3”.

• Debris can accumulate anywhere on the rider, especially on horizontal

surfaces. Additional cleaning may be necessary when mowing in dry

conditions or when mulching.

• Fuel leaks/spills, oil leaks/spills and excess lubrication can also become

collections sites for debris. Immediate repair and cleaning up oil or fuel spills

can help reduce fire hazards.

• In addition to cleaning the rider before operating and storing, do not

attempt to mow unusually tall grass (10” or higher), dry grass (e.g., pasture)

or piles of dry leaves. Dry grass or leaves may contact the engine exhaust

and/or build up on the mower deck presenting a potential fire hazard.

Battery

Clean the battery by removing it from the riding mower and washing with a

baking soda and water solution. If necessary, scrape the battery terminals with a

wire brush to remove deposits. Coat terminals and exposed wiring with grease or

petroleum jelly to prevent corrosion.

The battery is sealed and is maintenance-free. Acid levels cannot be checked.

• Always keep the battery cables and terminals clean and free of corrosive

build-up.

• After cleaning the battery and terminals, apply a light coat of petroleum jelly

or grease to both terminals.

• Always keep the rubber boot positioned over the positive terminal to prevent

shorting.

Important: If removing the battery for any reason, disconnect the NEGATIVE

(Black) wire from it’s terminal first, followed by the POSITIVE (Red) wire.

When re-installing the battery, always connect the POSITIVE (Red) wire its

terminal first, followed by the NEGATIVE (Black) wire. Be certain that the

wires are connected to the correct terminals; reversing them could change

the polarity and result in damage to your engine’s alternating system.

Loading ...

Loading ...

Loading ...