Loading ...

Loading ...

Loading ...

48

ENGLISH

- Above setup must be done for all HR unit valves.

- The valve that is not connected with any indoor unit should be

addressed with any other number than used address numbers of the

valves connected with indoor units.

(The valves does not work if the address numbers are same.)

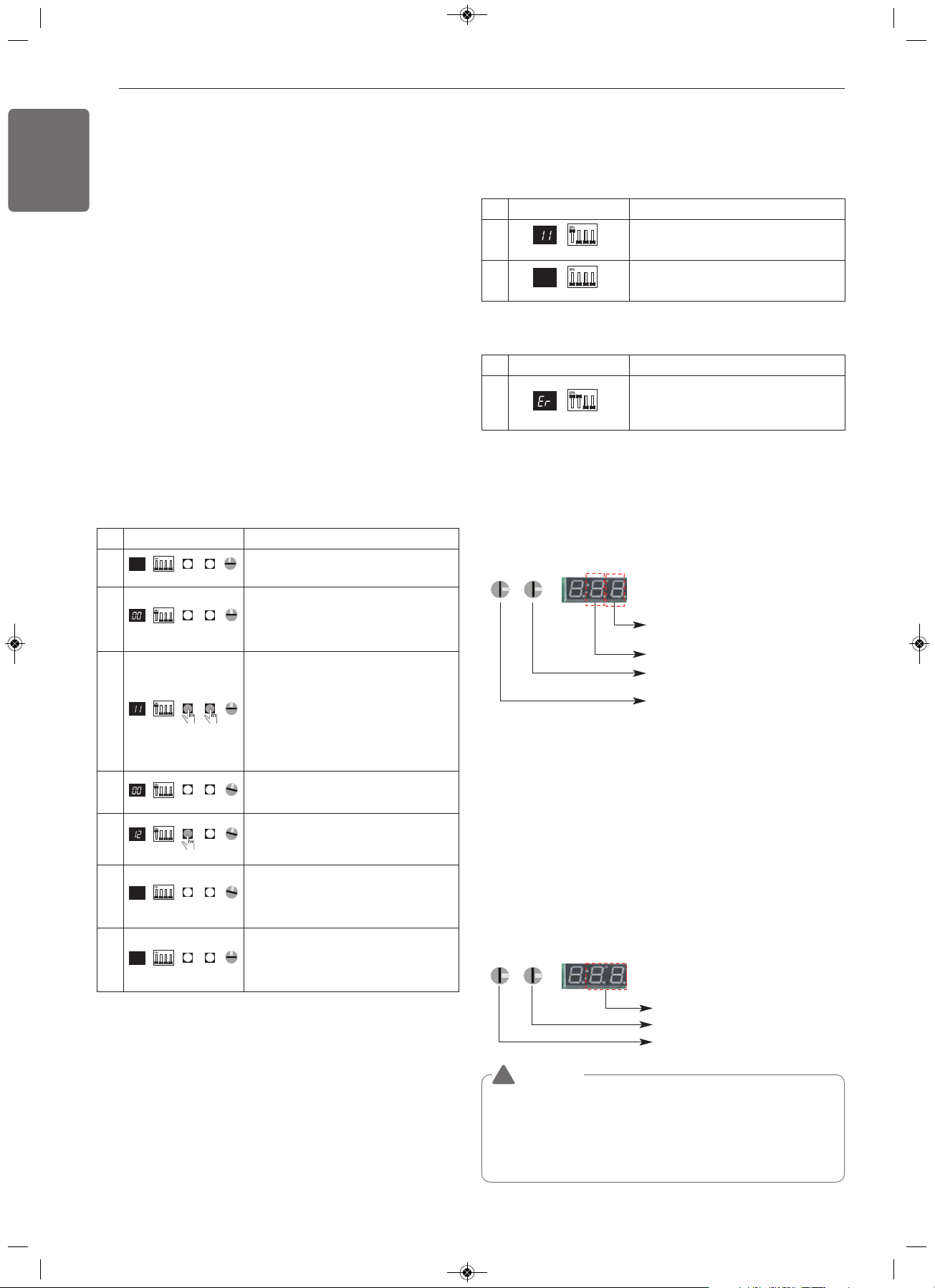

No. Display and setup Setup and Contents

1

- Operation: None

- Display: None

2

- Operation : Turn DIP S/W No.1 on to

address valve #1

- Display : Existing value saved in

EEPROM is displayed in 7-SEG.

3

- Operation : Set the digit of 10(1) to the

number in Group High data of the wired

remote control connected to the

corresponding indoor unit to the valve

#1 by pressing left tack S/W.

- Display : Digit increasing with the times

of pressing tack S/W is displayed in left

7-SEG.

4

- Operation : SW05M : 1

- Display : Display former value.

5

- Operation : Setting No. using SW03M

and SW04M, SW05M : 1

- Display : Display setting value.

6

- Operation : Turn DIP S/W No.1 off to

save the address of valve #1

- Display : "11" displayed in 7-SEG

disappears.

7

- Operation : Return valve of addressing

HR unit.

- Display : None

7-SEG SW01M SW03M SW04M

0

SW05M

7-SEG SW01M SW03M SW04M

SW05M

0

7-SEG SW01M SW03M SW04M

SW05M

0

1

7-SEG SW01M SW03M SW04M

SW05M

7-SEG SW01M SW03M SW04M

SW05M

1

7-SEG SW01M SW03M SW04M

SW05M

1

7-SEG SW01M SW03M SW04M

SW05M

0

No. Display and setup Setup and Contents

1

- Operation: Turn DIP S/W No.1 on.

- Display: "11" is displayed in 7-SEG

2

- Operation: Turn DIP S/W No.1 off

- 7-SEG disappeared

7-SEG SW01M

7-SEG SW01M

No. Display and setup Setup and Contents

1

- Operation: more than 2 DIP switches

turned on.

- Display: "Er" is displayed in 7-SEG

7-SEG SW01M

ROTARY 01 ROTARY 02

0

0

The connected port number of HR

unit

The connected HR unit number

The auto addressing number of indoor

unit (digit of 1)

The auto addressing number of indoor

unit (digit of 10)

No. of Indoor unit.

No. of HR unit branch.

No. of HR unit.

ROTARY 01 ROTARY 02

7 segment

0

0

Setting method of Master indoor unit in zoning

1 Turn DIP switch 5,6,10 on at system off.

2 Set the left Rotary switch for HR unit.(Rotary switch No. "0" ‘ HR unit

No. "1")

3 Set the right Rotary switch for IDU unit.(Rotary switch No. "0" ‘ HR

unit branch No. "1")

4 Display the Master IDU No. of the HR unit on 7segment.(Default

display is "00" on 7segment)

5 Press the black button.(The IDU No. increase every 1 second in the

zoning )

6 Set the Master IDU.(Press the red button during 1.5 seconds stop

twinkling)

Method of checking the pipe detection result

at outdoor unit

1 Wait for 5 minutes, after Pipe detection is completed.

2 Turn on the No.10,14,16 DIP S/W of SUB PCB at master unit

3 Check the data on 7- segment, switching rotary 01,02.

Identification of Manual Valve ID (Address)

Method of checking the pipe detection result

at HR unit

In case that an indoor unit of central control address "11" is connected

to a valve #1 of an HR unit

Example of manual valve addressing (Zoning

setting)

(In case that an indoor unit of central control address "11" is connected

to a valve #1 of an HR unit)

Zoning control is connecting 2 or more indoor units at one pipe of HR

unit. In case of Zoning control, in order to set controls with multiple

indoor units connection uses the rotary switch. Namely, only the rotary

switch changes from same valve set condition and set indoor units

connection.

1 On DIP switch of the corresponding valves and sets the rotary

switch at 0.

2 Setting the number with tact switch.

3 In case of addition of indoor units to same port, increases 1 with the

rotary switch and sets number with tact switch.

4 In case of checking the number which the corresponding valve is

stored, turn on DIP switch and set the number of rotary switch.

5 Indoor units set available 7 per a port(rotary switch 0~6), in case of

setting above of 7 with rotary switch, it will display error.

6 Setting the rotary switch on original condition(HR unit number set

conditions) after all finishing a piping setting.

7 The rotary switch set value of above number of indoor units which

is connected with FF and prevents a malfunction.

(Example: The case where 3 indoor units is connected in piping 1,

sets from rotary switch 0,1,2 and 3,4,5 with FF set)

- Prerequisite for manual valve addressing: central control address of

each indoor unit must be preset differently at its wired remote

control.

• Waiting for 80 seconds after power on.

• The zoning information and Master IDU information remove from

EEPROM after Auto-addressing.

• If there is installed the central control, it is impossible setting of

Master IDU in zoning.

CAUTION

!

1,MFL68980308,영영 2018. 11. 13. 영영 3:24 Page 48

Loading ...

Loading ...

Loading ...