Loading ...

Loading ...

Loading ...

26 INSTALLING THE GAS ELEVATED COOKER

Testing Burner Performance

• Observe the flame appearance on each burner when

set to max. If it is smaller or larger than expected,

then the injector size needs checking (refer to table).

• When maximum flame appearance is correct, check

the turn down setting on each burner. If incorrect,

proceed as follows:

WARNING

WARNING

Disconnect electric power.

1. Remove the control panel and adjust the bypass

screw when valve is set to maximum. The screw is

mounted on the body of each hotplate control valve.

2. Check the ignition on all burners both separately and

in combination.

3. Check the operation of the electrical components,

if applicable.

4. When operating correctly, show customer how to use

the cooker.

5. If not operating correctly, advise the customer to ring

Electrolux Customer Service Centre. Place a warning

sign on cooker or if dangerous, disconnect cooker.

Checking the gas supply

1. Check the manometer zero point is correct.

2. Connect the manometer to the cooker pressure

test point. This is located on the regulator or LPG

inlet fitting.

3. Turn on the gas supply and the electricity (if

applicable) and try to ignite the gas.

NOTE: It will take additional time to light the gas for the

first time, as air needs to be purged from the pipes.

4. Check the operating pressure for the particular gas

type (see ‘Gas Type’ table).

• For LPG cookers: Adjust the regulator if

necessary (this may be remote from the cooker).

• For Natural Gas cookers: Regulators are supplied

pre-adjusted and configured by the component

maker for use with Natural Gas. The appliance

installer is not required to make an adjustment

to obtain the correct outlet pressure setting.

An arrow on the base of the regulator indicates

the direction of the gas flow when the inlet and

outlet of the regulator are orientated correctly.

5. When the regulator has been fitted check for leaks

from the connections with soapy water.

Checking regulator function

With the appliance operating, check the outlet pressure:

1. When all the burners of the appliance are operating

at maximum.

2. When the smallest burner of the appliance is

operating at minimum.

Under both these conditions the outlet pressure

should not vary from nominal operating pressure

of 1.0kPa by more then ± 20% (ie ±0.20kPa for

Natural Gas).

If the regulator does not appear to be performing

satisfactorily then check the following points:

1. If the outlet pressure is consistently too low then

• the inlet pressure may be too low and

adjustment of an upstream regulator may be

needed, or

• an upstream regulator or valve with insufficient

flow capacity may be present in the gas supply

line. It may be necessary to repeat the checks

whilst measuring both the inlet and outlet

pressure to determine if the inlet pressure is in

the range 1.13-5kPa.

2. Check that the regulator has been fitted to the gas

supply line in the correct orientation.

3. Replace the regulator if it fails to perform after

the checks.

INSTALLING THE GAS ELEVATED COOKER GAS CONVERSION PROCEDURE

10. Re-fit oven supply pipe to burner and replace

the backpanel.

11. Place gas sticker supplied onto rear panel over

existing sticker.

12. Remove the regulator and replace with test point

adaptor supplied for ULP or propane. For NG

remove test point adaptor and replace with regulator

supplied. Note that ULP and propane both use the

same test point adaptor.

13. Turn on gas & check for leaks.

14. Check and adjust the test point pressure according

to the procedure in the installation instructions.

15. Light all burners and operate at maximum.

16. For each hotplate and grill burner adjust the burner

to minimum and screw in the bypass screw until

a small stable flame results. Adjust the burner to

maximum and back to minimum to ensure correct

adjustment.

17. Re-fit the control panel & re-connect to electrical

power.

1. Turn off gas supply to appliance.

2. Disconnect appliance from electrical power

(if applicable).

3. Pull off control knobs and remove control panel

(two screws).

4. Remove grill burner injector and replace with

appropriate injector.

5. Fit aeration control (shutter) supplied to grill burner

as required. See page 10 of instruction book for

grill shutter assembly diagram. Note that ULP and

propane use the same aeration control.

6. Remove existing hotplate injectors and fit appropriate

injectors supplied.

7. Remove by pass screw in oven thermostat and fit

appropriate by pass screw supplied. Note that ULP

and propane use the same by-pass screw.

8. Remove backpanel and disengage oven supply pipe

from oven burner.

9. Remove oven injector and replace with injector

supplied.

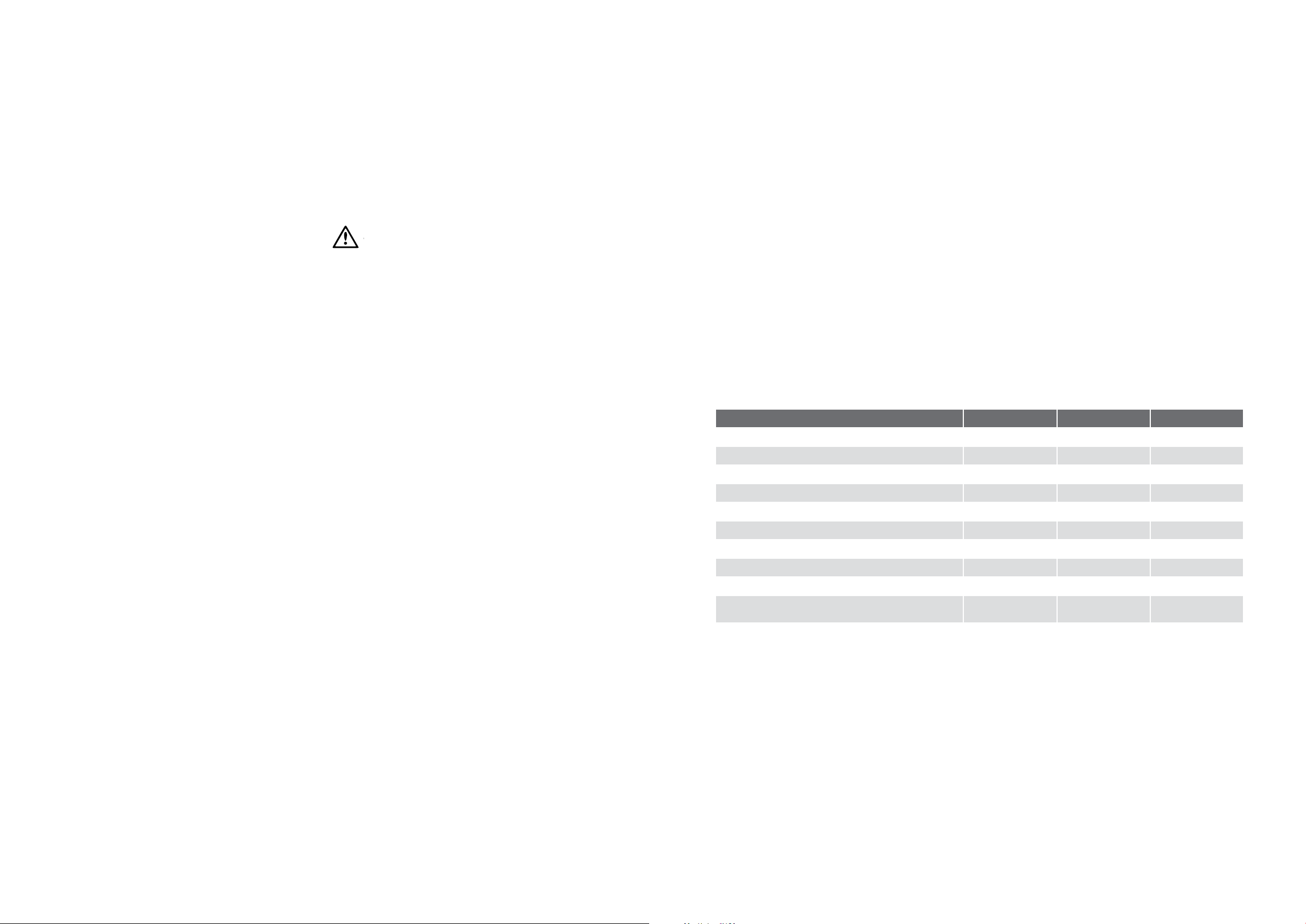

INJECTORS NATURAL GAS UNIVERSAL LPG PROPANE

Wok burner 1.75 mm 1.00 mm 0.95 mm

Large hotplate burner 1.60 mm 0.90 mm 0.95 mm

Medium hotplate burner 1.35 mm 0.70 mm 0.82 mm

Small hotplate burner 1.00 mm 0.55 mm 0.62 mm

Grill burner 1.50 mm 0.82 mm 0.82 mm

Oven burner 1.60 mm 0.82 mm 0.95 mm

Thermostat Bypass Screw 0.73 mm 0.45 mm 0.45 mm

Regulator NG Regulator

LP Test Point

Adaptor

LP Test Point

Adaptor

27GAS CONVERSION PROCEDURE

Loading ...

Loading ...

Loading ...