Loading ...

Loading ...

Loading ...

24 25INSTALLING THE GAS ELEVATED COOKERINSTALLING THE GAS ELEVATED COOKER

INSTALLING THE GAS ELEVATED COOKER

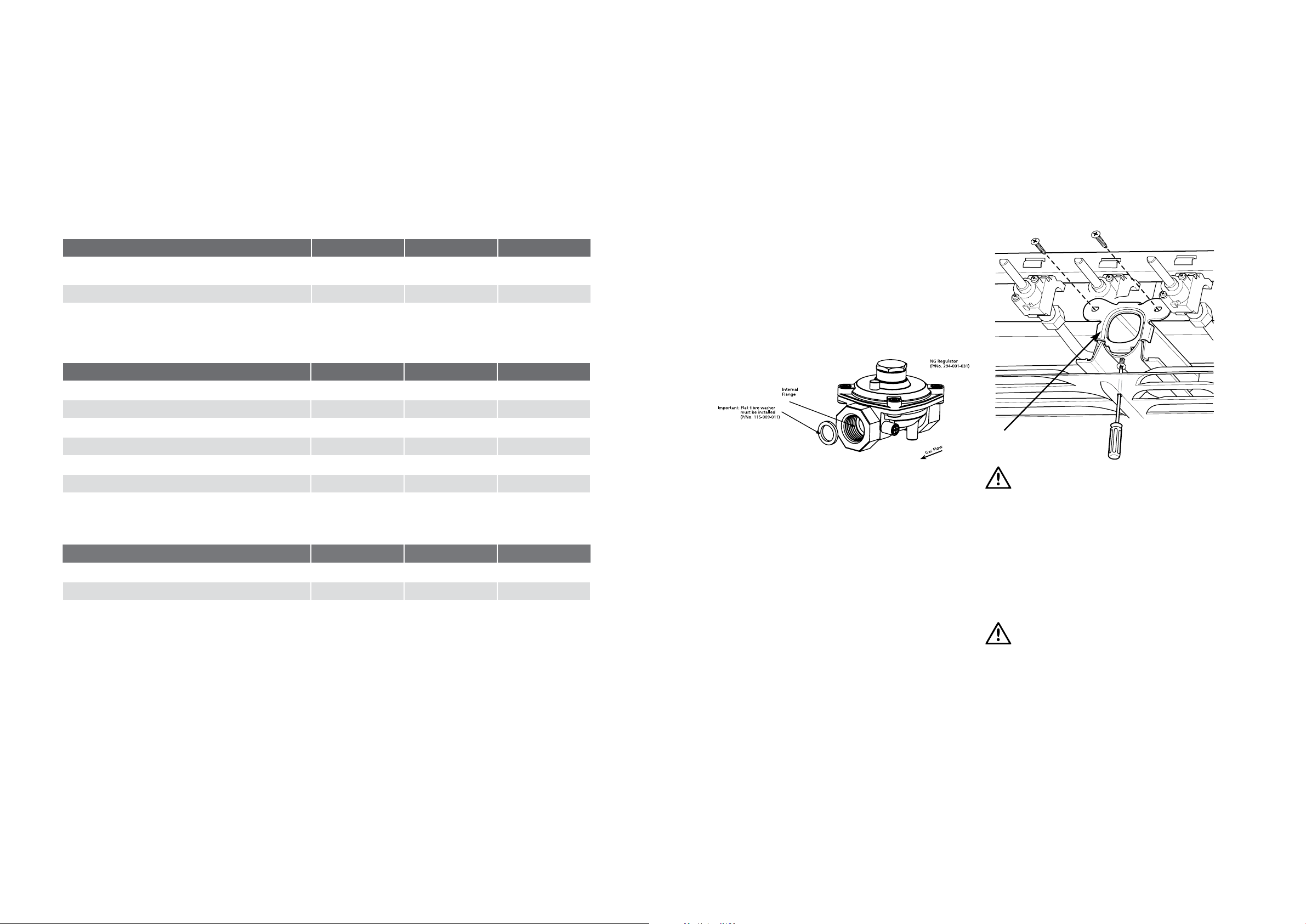

Operation on SNG

• If the cooker is to be used with SNG, then the grill

burner MUST be modified by the replacement of the

shutter, which fits into the throat of the grill burner.

• A conversion kit can be obtained by contacting the

Customer Care Centre.

Restraining Device

Anchor Points

Connection

Gas

Point

150mm

650mm

Grill shutter

WARNING

WARNING

Disconnect electric power before removing control panel.

1. Remove the control panel.

2. Remove the existing NG shutter securing screw (refer

to diagram above) and slide upwards to disengage

from grill burner.

3. Slide the SNG shutter into position and secure with

screws.

Testing the gas cooker

WARNING

WARNING

You MUST test the cooker after installation, before you

hand it over to the customer.

You MUST have a manometer and a connecting tube.

Gas connection

Read these points before connecting to the gas supply:

• An NG regulator or a LPG test point fitting

is supplied.

• Ensure installation allows withdrawal of appliance.

Operation on NG

1. The appliance regulator be MUST be orientated so

that the pressure nipple is accessible.

2. The arrow showing the direction of flow MUST be

pointed correctly.

3. The regulator has ½” BSP internal thread at the inlet

and outlet.

4. The flat fibre washer provided with the regulator

MUST be used when making the gas connection.

Operation on universal LPG/propane

1. The appliance inlet fitting provided MUST be

orientated so that the pressure nipple is accessible.

2. The inlet fitting has ½” BSP internal thread at the inlet

and outlet.

The cooker also comes supplied with a LPG gas conversion

kit, should you need to convert the gas from NG to LPG.

Alternatively, you can obtain these by contacting the

Customer Care Centre. Before installation check that

the cooker is suitable for the gas supply. For LPG it is

recommended to have the conversion completed prior to

installation on the bench.

The following table shows the supply and operating

pressures for various supplies.

INSTALLING THE GAS ELEVATED COOKER

Gas requirements

This appliance must be installed by an authorised person,

according to all codes and regulations of:

• AS/NZS 5601.1 (particular attention to clause 6.10.1 and

figure 6.3 on page 97, and clause 6.10.1.5 and 6.10.1.6

• Local gas fitting regulations, municipal building codes

and other statutory regulations.

GAS TYPE NATURAL GAS UNIVERSAL LPG PROPANE

Supply pressure at inlet to appliance regulator

(if fitted)

1.13 (kPa)

Minimum

2.75* (kPa) 2.75* (kPa)

Operate pressure at appliance test point 1.00 (kPa) 2.75 (kPa) 2.75 (kPa)

* If the regulator is placed upstream of the cooker inlet, as is normal for cookers operating on LPG, then the supply

pressure and operating pressure are the same.

The following table shows the injector sizes for each burner.

INJECTOR NATURAL GAS UNIVERSAL LPG PROPANE

Low heat burner 1.00 mm 0.55 mm 0.62 mm

Medium heat burner 1.35 mm 0.70 mm 0.82 mm

High heat burner 1.60 mm 0.90 mm 0.95 mm

Grill – main injector 1.50 mm 0.82 mm 0.82 mm

Oven – main injector 1.60 mm 0.82 mm 0.95 mm

Oven – bypass screw 0.73 mm 0.45 mm 0.45 mm

Checking pipe size

To work out a suitable pipe size for connection use the information in this table.

NATURAL GAS UNIVERSAL LPG PROPANE

Configuration STD Hob STD Hob STD Hob

Hourly gas consumption for cooker 57.2MJ 45.7MJ 56.5MJ

Also use information about the length of the run, number of elbows, tees and bends, the available service pressure and

the supply requirements. AS/NZS 5601.1 will help you with this matter.

Wiring connection for gas cooker (if applicable)

To allow for disconnection of the appliance after

installation, the plug must be accessible after installation.

If the supply cord is damaged, it must be replaced by

the manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

Loading ...

Loading ...

Loading ...