Loading ...

Loading ...

Loading ...

22 23INSTALLING THE GAS ELEVATED COOKERINSTALLING THE ELECTRIC ELEVATED COOKER

• In order to avoid overheating of the cooker,

the cooker must not be installed behind a

decorative door.

• The appliance MUST be installed using the

flexible hose supplied.

• The vents, openings and air spaces MUST NOT

be blocked.

• You MUST NOT pull the cooker by the door

handles or the splashback.

• The cooker MUST be checked every five years.

• The cooker MUST NOT be used as a space heater.

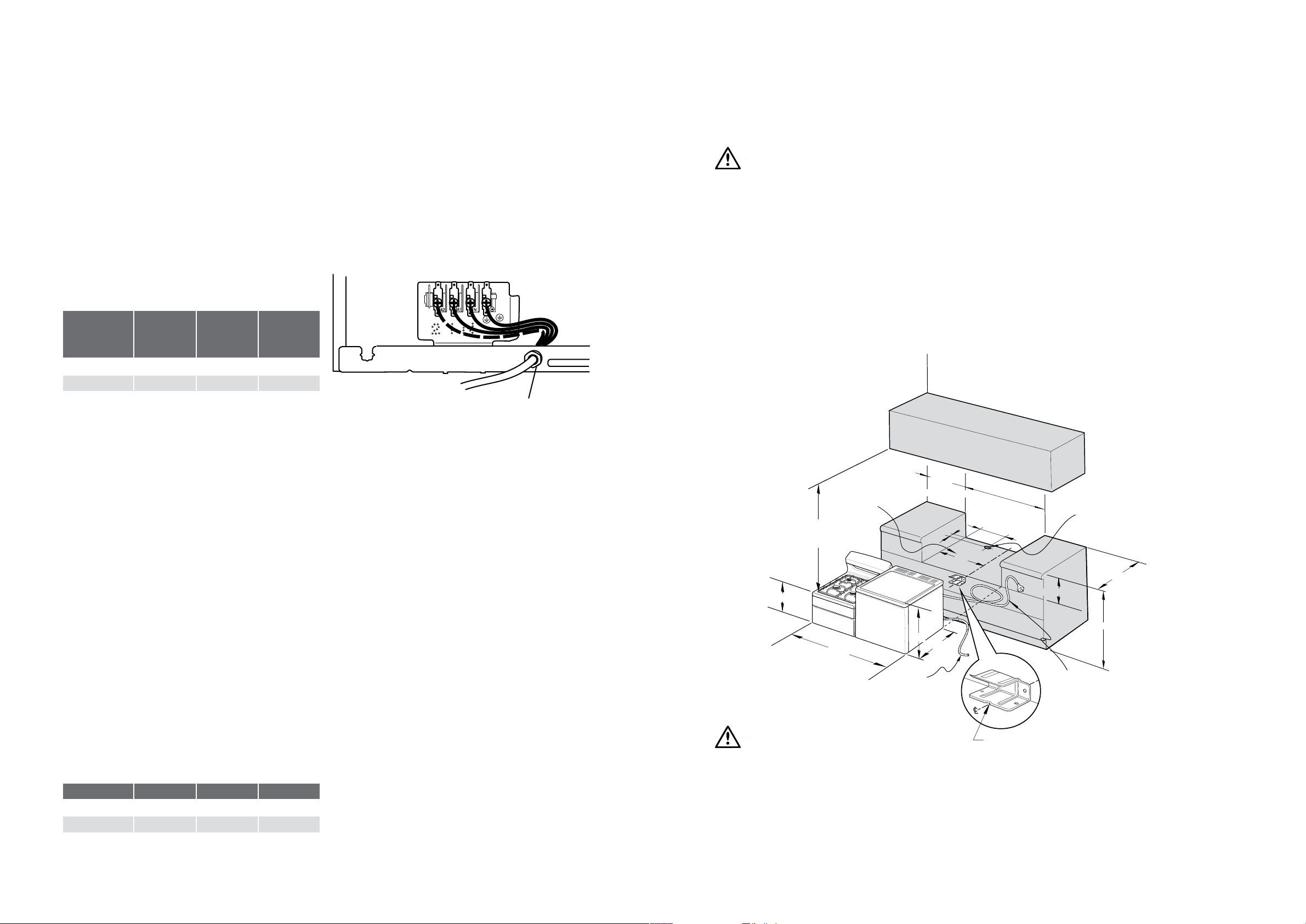

Locating the cooker

Study the diagrams below to be sure of the dimensions

required to locate the cooker safely.

INSTALLING THE GAS ELEVATED COOKER

Safety Warnings about installation

WARNING

WARNING

• The cooker MUST be installed and serviced by a

qualified technician.

• A Certificate of Compliance MUST be supplied to

be kept by the customer.

• The packing materials MUST be removed before

you install the cooker.

• You MUST follow the installation instructions in

this booklet.

• The surrounding kitchen cabinets MUST be able

to withstand 85°C. Electrolux Products WILL

NOT accept responsibility for damage caused

by installation into kitchen cabinets which cannot

withstand 85°C.

Hard wiring

1. To gain access to the terminal block, remove the

small rear panel by unscrewing the two screws.

2. Fit wires through the hole in the base using the

appropriate gland to protect insulation of wires

from the hole edge.

3. Set the length of wiring from the gland to terminal

block, ensuring length is sufficient but not excessive.

4. Make connections to terminals.

5. Replace rear panel.

A2

A1

N

INSTALLING THE ELECTRIC ELEVATED COOKER

Electric wiring requirements

The cooker MUST be installed in compliance with:

• Wiring connections in AS/NZS3000 wiring rules.

• Local regulations, municipal building codes and other

statutory regulations.

• Data plate – Gives information about the rating and

is located behind the bottom of the oven door.

For New Zealand only: The cooking range must be

connected to the supply by a supply cord fitted with

the appropriately rated plug that is compatible with the

socket-outlet fitted to the final sub-circuit in the fixed

wiring that is intended to supply this cooking range.

See table below:

MODEL

CURRENT

RATING

(AMPS)

WIRE

SECTION

(MM2)

MINIMUM

TEMP

RATING

(°C)

WDE135WA 50 6 75

WDE147WA 50 6 75

• A functional switch MUST be provided near the

appliance in an accessible position (AS/NZS3000 –

Clause 4.7.1).

• Wiring MUST be protected against mechanical failure

(AS/NZS3000 – Clause 3.9).

• The cooker requires a means of all pole disconnection

incorporated into the fixed wiring. This MUST have a

disconnection gap of 3mm.

• The cooker MUST be properly earthed.

• This product has passed the insulation resistance

test after manufacture. If the resistance reading is low

at installation, it is probably caused by moisture from

the atmosphere being absorbed by the elements

after the range has been produced. (Pass at 0.01MΩ

AS/NZS 3000 Wiring Rules Clause 8.3.6.2)

• When connections are made to a multiphase

230/240V supply, the bridge piece MUST be removed

from between the active connections.

• If the supply cord is damaged, it must be replaced

by the manufacturer, its service agent or similarly

qualified persons in order to avoid a hazard.

IMPORTANT: Before you cook in your new oven

it is important that the protective oils used in the

manufacture of the product be removed. Refer to

‘Before Operating your Appliance for the First Time’

in the Using The Oven section.

300 Maximum

600

Locating V

900

1095 Minimum

280 R.H. Oven

720 L.H. Oven

1.7m

Gas supply hose

2.0m

Electrical service

cord (if fitted)

50mm diameter access

hole to gas supply and

power point (if required)

1085

320

500 minimum

to combustible

material

40

762

520

620

120

minimum

to

combustible

material

Dimension to centre

line of anti-tilt plate

WARNING

WARNING

In order to avoid accidental tipping of the appliance (for

example, by a child climbing onto the open oven door),

the anti-tilt plate MUST be installed.

Position the anti-tilt plate to the rear wall and 762mm

from the left side of the wall. Dimension to the “v” at

the front of the anti-tilt plate and then securely fix

with fasteners.

MODEL TOTAL kW A1 kW A2 kW

WDE135WA 10.1 4.1 6.0

WDE147WA 10.5 4.1 6.4

Rated power input

Gland

Loading ...

Loading ...

Loading ...