Documents: Go to download!

User Manual

- User Manual - (English)

- HDSL24UL Product Guide - French - (French)

- HDSL24UL Product Guide - Spanish - (Spanish)

- LiftMaster HDSL24UL Product Guide - English - (English)

- LiftMaster Gate Operator Solar Chart - (English)

- HD Gate Operator Brochure - English - (English)

- HD Gate Operator Brochure - French - (French)

- Solar_Credit_Letter_English - (English)

- HD Gate Operator Brochure - Spanish - (Spanish)

- LiftMaster HDSL24UL, HDSW24UL Wiring Diagram - English, French - (English)

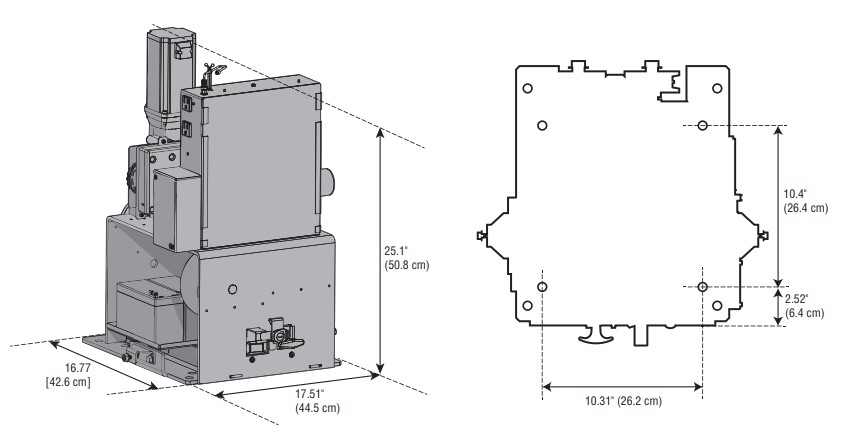

- HDSL24UL Product Drawing - (English)

- LiftMaster HDSL24UL Installation Manual - French - (French)

- LiftMaster HDSL24UL Installation Manual - Spanish - (Spanish)

- LiftMaster HDSL24UL Data Sheet - English - (English)

- OPERATION

- MAINTENANCE

- TROUBLESHOOTING

- Operator Specifications

Table of contents

INSTALLATION MANUAL VEHICULAR SLIDE GATE OPERATOR

OPERATION

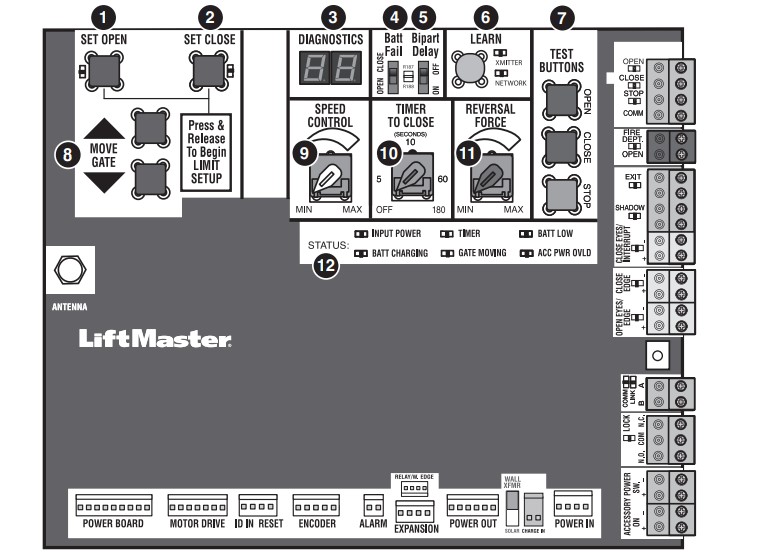

Control Board Overview

1 SET OPEN Button: The SET OPEN button sets the OPEN limit. See Adjustment section.

2 SET CLOSE Button: The SET CLOSE button sets the CLOSE limit. See Adjustment section.

3 DIAGNOSTICS Display: The diagnostics display will show the operator type, firmware version, and codes. The operator type will display as "HL" followed by a "24" which indicates the operator type as HDSL24UL. The firmware version will show after the operator type, example "1.2".

4 BATT FAIL:

- When AC power is OFF and battery voltage is critically low the gate will latch at a limit until AC power is restored or batteries voltage increases.

- Option select switch set to OPEN forces gate to automatically open and then latch at the OPEN limit until AC power is restored or battery voltage increases.

- Option select switch set to CLOSE forces gate to latch at CLOSE limit if at CLOSE limit or on next CLOSE command until AC power restored or battery voltage increases.

- Constant pressure on a hard command input overrides to open or close the gate.

- Critically low battery is less than 23 Vdc.

5 BIPART DELAY Switch: The LOCK/BIPART DELAY switch is used only for dual gates. See Bipart delay/synchronized closed page 21.

6 LEARN Button: The LEARN button is for programming remote controls and the network.

7 TEST BUTTONS: The TEST BUTTONS will operate the gate (OPEN, STOP and CLOSE).

8 MOVE GATE Buttons: The MOVE GATE buttons will either open or close the gate when the operator is in Limit setting mode. See Adjustment section.

9 SPEED CONTROL dial: Sets maximum gate speed, see Speed Control page 24.

10 TIMER-TO-CLOSE dial: The TIMER-TO-CLOSE (TTC) dial can be set to automatically close the gate after a specified time period. The TTC is factory set to OFF. If the TTC is set to the OFF position, then the gate will remain open until the operator receives another command from a control. Rotate the TIMERTO-CLOSE dial to the desired setting. The range is 0 to 180 seconds, 0 seconds is OFF. NOTE: Any radio command, single button control, or CLOSE command on the control board prior to the TTC expiring will close the gate. The TTC is reset by any signals from the open controls, loops, close edges, and close photoelectric sensors (IR’s).

11 REVERSAL FORCE dial: The REVERSAL FORCE dial fine tunes the force, see Fine Tune the Force page 24.

12 STATUS LEDs: The STATUS LEDs indicate the status of the operator. See Status LED Chart in the Troubleshooting section.

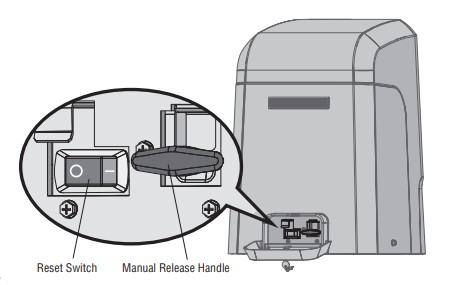

Manual Disconnect

- Set the reset switch to the RESET position.

- Pull the manual release handle.

To resume normal function, release the handle and set the switch to NORMAL OPERATION. On a dual gate application the handle must be released on both operators.

Reset Switch

The reset switch has the following functions:

- Set the switch to the RESET position to disable gate operation. Use this switch before servicing the gate or manually disconnecting the gate. The stop LED will be illuminated.

- To hold the gate open, run the gate to the open position and then set the switch to the RESET position.

- Toggle the reset switch to RESET then back to NORMAL OPERATION when the operator alarm has been set off, see page 32.

- To put the operator into high band programming mode, give the operator an OPEN command. Within 30 seconds, when the gate is at the open limit, toggle the reset switch between RESET and NORMAL OPERATION three times.

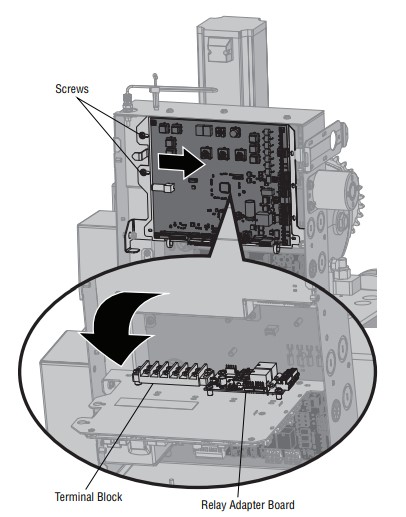

Relay Adapter Board and Terminal Block Access

To access the relay adapter board and terminal block, loosen the two screws of the control board bracket, slide the whole bracket to the right, then swing open.

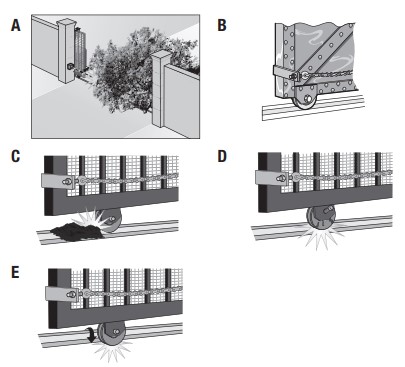

Operator Alarm

|

When the inherent force of the operator detects the following twice consecutively, the alarm will sound up to 5 minutes and the operator will need to be reset. A. The gate is hitting an obstruction. B. The gate does not meet specifications. C. Debris is on the gate's track such as mud, rocks, dirt, etc. D. The gate has one or more broken axles or wheels. E. The gate wheel is off the gate rail. The operator alarm will beep 3 times with a command if the battery is low. Remove any obstructions or repair gate system. Toggle the reset switch to RESET then back to NORMAL OPERATION to shut off the alarm and reset the operator. After the operator is reset, normal functions will resume. |

|

Remote control

There are 3 different options for programming the remote control depending on how you would like the remote control to function, see page 26.

Single Button Open Only

- When gate is in the closed position, activation of the remote control button will open the gate. The Timer-to-Close can be set to close the gate.

Single Button Control (SBC) Functionality

- Program one remote control button as an open, close, and stop

- When gate is in the closed position, activation of the remote control button will open the gate. During the open cycle another activation of the remote control will stop the gate and the next activation of the remote control will close the gate.

- When the gate is in the open position, activation of the remote control button will close the gate. If the remote control is activated while the gate is closing, the gate will stop and the next activation will open the gate.

Three Button Remote Control

- Program each remote control button as an open, close, and stop.

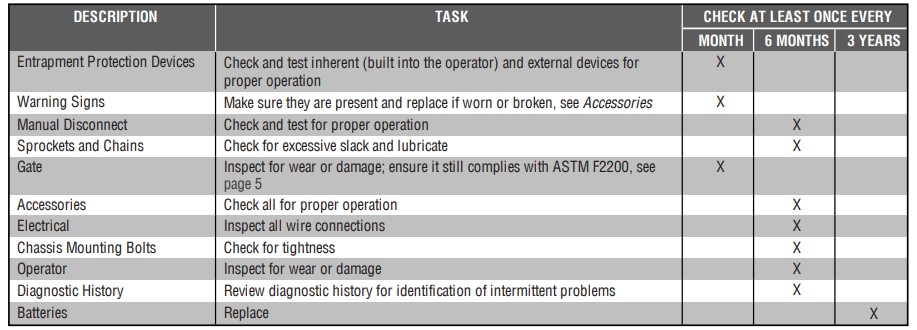

MAINTENANCE

Maintenance Chart

Disconnect all power (AC, solar, battery) to the operator before servicing.

NOTES:

- Limits may have to be reset after any major drive chain adjustments.

- If lubricating chain, use only lithium spray. Never use grease or silicone spray.

- It is suggested that while at the site voltage readings be taken at the operator. Using a digital voltmeter, verify that the incoming voltage to the operator is within ten percent of the operator’s rating.

Batteries

Batteries will degrade over time depending on temperature and usage. The operator alarm will beep 3 times with a command if the battery is low. Batteries do not perform well in extremely cold temperatures. For best performance, the batteries should be replaced every 3 years. Use only LiftMaster part 29-NP712 for replacement batteries. The batteries contain lead and need to be disposed of properly.

The operator comes with two 7AH batteries. Two 33AH batteries (A12330SGLPK), with battery harness model K41-0102-000 (not provided), may be used in place of the 7AH batteries.

33AH batteries are NOT compatible if transformer kit model 3PHCONV is installed.

Drive Train

Over time, the drive chain on the operator will stretch and need to be tightened. To tighten the drive chain adjust either of the two chain eye bolts.

NOTE: The chain should have no more than 1 inch of sag for every 10 feet of chain length.

TROUBLESHOOTING

Troubleshooting Chart

| SYMPTOM | POSSIBLE CAUSES | SOLUTIONS |

|---|---|---|

| Operator does not run and diagnostic display not on. |

a. No power to control board b. Open fuse c. If on battery power only, low or dead batteries d. Inoperable control board e. Inoperable power board |

a. Check AC and battery power b. Check fuses on the power board c. Charge batteries by AC or solar power or replace batteries d. Replace inoperable control board e. Replace power board |

| Control board powers up, but motor does not run. |

a. Reset switch is in the RESET position b. Jumper is not in place for stop circuit c. If on battery power only, low or dead batteries d. Open or close input active e. Entrapment protection device active f. Vehicle loop detector or probe active g. Inoperable control board h. Inoperable motor or motor control module |

a. Set reset switch to NORMAL OPERATION b. Put a jumper on the stop circuit c. Charges batteries by AC or solar power or replace batteries d. Check all open and close inputs for a “stuck on” input e. Check all entrapment protection device inputs for a “stuck on” sensor f. Check all vehicle detector inputs for a “stuck on” detector g. Replace inoperable control board h. Replace motor or motor control module |

| Gate moves, but cannot set correct limits. |

a. Gate does not move to a limit position b. Gate is too difficult to move c. Limits are set too close |

a. Use manual disconnect, manually move gate, and ensure gate moves easily limit to limit. Repair gate as needed. b. Gate must move easily and freely through its entire range, limit to limit. Repair gate as needed. c. Ensure the gate moves at least four feet between the OPEN limit and the CLOSE limit. |

| Gate does not fully open or fully close when setting limits |

a. Gate does not move to a limit position b. Gate is too difficult to move |

a. Use manual disconnect, manually move gate, and ensure gate moves easily limit to limit. Repair gate as needed. b. Gate must move easily and freely through its entire range, limit to limit. Repair gate as needed. |

| Operator does not respond to a wired control/command (example: open, close, SBC, etc.) |

a. Check open and close command input LEDs b. Reset switch is in the RESET position c. If on battery power only, low or dead batteries d. Entrapment protection device active e. Vehicle loop detector or vehicle probe active |

a. Check all open and close inputs for a “stuck on” input b. Set reset switch to NORMAL OPERATION, see page 31 c. Charges batteries by AC or solar power or replace batteries d. Check all entrapment protection device inputs for a “stuck on” sensor e. Check all vehicle detector inputs for a “stuck on” detector |

| Operator does not respond to a wireless control or transmitter |

a. Check XMITTER LED when wireless control is active b. Reset switch is in the off position c. Poor radio reception |

a. Activate wireless control and check XMITTER LED is on. Re-learn wireless control/transmitter to control board. Replace wireless control as needed. b. Set reset switch to NORMAL OPERATION, see page 31 c. Check if similar wired control operates correctly. Check if wireless controls works properly when within a few feet of operator. Check operator’s antenna and antenna wire. Check other wireless controls or devices. |

| Gate stops during travel and reverses immediately. |

a. Control (open, close) becoming active b. Vehicle loop detector active c. Low battery voltage d. Inherent entrapment protection was activated while moving |

a. Check all open and close inputs for an active input b. Check all vehicle detector inputs for an active detector c. Battery voltage must be 23 Vdc or higher. Charge batteries by AC or solar power or replace batteries d. If there are no obstructions in gate path, manually disconnect the gate, and ensure it moves easily limit to limit. Repair gate as needed. |

| Gate opens, but will not close with transmitter or Timer-to-Close. |

a. Open control active b. Vehicle loop detector active c. Loss of AC power with AC FAIL set to OPEN d. Low battery with LOW BATT set to OPEN e. Fire dept input active f. Timer-to-Close not set g. Close entrapment protection device active |

a. Check all open inputs for an active input b. Check all vehicle detector inputs for an active detector c. Check AC power and AC Fail option setting d. Check if AC power is available. If no AC power, then running on batteries and battery voltage must be 23 Vdc or higher. Charge batteries by AC or solar power or replace batteries. e. Check Fire Dept input f. Check Timer-to-Close (TTC) setting g. Check all entrapment protection device inputs for an active sensor |

| Gate closes, but will not open. |

a. Vehicle loop detector active b. Low battery with LOW BATT option set to CLOSE |

a. Check all vehicle detector inputs for an active detector b. Check if AC power is available. If no AC power, then running on batteries and battery voltage must be 23 Vdc or higher. Charge batteries by AC or solar power or replace batteries. |

| Exit loop activation does not cause gate to open. |

a. Exit vehicle detector setup incorrectly b. Inoperable exit loop detector c. Low battery with LOW BATT option set to CLOSE |

a. Review exit loop detector settings. Adjust settings as needed. b. Replace inoperable exit loop detector. c. Check if AC power is available. If no AC power, then running on batteries and battery voltage must be 23 Vdc or higher. Charge batteries by AC or solar power or replace batteries. |

| Interrupt loop does not cause gate to stop and reverse |

a. Vehicle detector setup incorrectly b. Inoperable vehicle loop detector c. Anti-tail set to ON |

a. Review Interrupt loop detector settings. Adjust settings as needed. b. Replace inoperable Interrupt loop detector. c. Set anti-tail to OFF. |

| Shadow loop does not keep gate at open limit. |

a. Vehicle detector setup incorrectly b. Inoperable vehicle loop detector |

a. Review shadow loop detector settings. Adjust settings as needed. b. Replace inoperable shadow loop detector. |

| Obstruction in gate's path does not cause gate to stop and reverse. | a. Force adjustment needed | a. Refer to the Adjustment section to conduct the obstruction test and perform the proper force adjustment that is needed. |

| Photoelectric sensor does not stop or reverse gate. |

a. Incorrect photoelectric sensor wiring b. Inoperable photoelectric sensor |

a. Check photoelectric sensor wiring. Retest that obstructing photoelectric sensor causes moving gate to stop, and may reverse direction. b. Replace inoperable photoelectric sensor. Retest that obstructing photoelectric sensor causes moving gate to stop, and may reverse direction. |

| Edge sensor does not stop or reverse gate. |

a. Incorrect edge sensor wiring b. Inoperable edge sensor |

a. Check edge sensor wiring. Retest that activating edge sensor causes moving gate to stop and reverse direction. b. Replace inoperable edge sensor. Retest that activating edge sensor causes moving gate to stop and reverse direction. |

| Alarm sounds for 5 minutes or alarm sounds with a command. | a. Double entrapment occurred (two obstructions within a single activation) | a. Check for cause of entrapment (obstruction) detection and correct. Press the reset button to shut off alarm and reset the operator. |

| Alarm beeps three times with a command. | a. Low battery | a. Check if AC power is available. If no AC power, then running on batteries and battery voltage must be 23 Vdc or higher. Charge batteries by AC or solar power or replace batteries |

| Alarm beeps when running. |

a. Expansion board setting b. Constant pressure to open or close is given |

a. Pre-warning is set to "ON" b. Constant pressure to open or close is given |

|

Expansion board function not controlling gate. |

a. Inoperable main board to expansion board wiring b. Incorrect input wiring to expansion board c. Inoperable expansion board or inoperable main board |

a. Check main board to expansion board wiring. If required, replace wire cable. b. Check wiring to all inputs on expansion board. c. Replace inoperable expansion board or main board |

| Maglock not working correctly. | a. Maglock wired incorrectly | a. Check that maglock is wired to N.C. and COM terminals. Check that maglock has power (do not power maglock from control board accessory power terminals). If shorting lock’s NO and COM wires does not activate maglock, then replace maglock or maglock wiring (refer to wiring diagram). |

| Solenoid lock not working correctly. | a. Solenoid wired incorrectly | a. Check that solenoid is wired to N.O. and COM terminals. Check that solenoid has power (do not power solenoid from control board accessory power terminals). If shorting lock’s NC and COM wires does not activate solenoid, then replace solenoid lock or solenoid wiring (refer to wiring diagram). |

| Switched (SW) accessory power remaining on. | a. In limit setup mode | a. Learn the limits |

| Accessories connected to switched (SW) accessory power not working correctly, turning off, or resetting. | a. Normal behavior | a. Move accessory to accessory power "ON" |

| Accessories connected to Accessory power not working correctly, turning off, or resetting |

a. Accessory power protector active b. Inoperable control board |

a. Disconnect all accessory powered devices and measure accessory power voltage (should be 23 – 30 Vdc). If voltage is correct, connect accessories one at a time, measuring accessory voltage after every new connection. b. Replace inoperable control board |

| Quick close not working correctly. |

a. Quick close setting incorrect b. Interrupt loop detector c. Inoperable expansion board |

a. Check that quick close setting is ON b. Check operation of interrupt loop detector c. Replace inoperable expansion board |

| Anti-tailgating not working correctly. |

a. Anti-tail setting incorrect b. Interrupt loop detector c. Inoperable expansion board |

a. Check that anti-tail setting is ON b. Check operation of Interrupt loop detector c. Replace inoperable expansion board |

| AUX relay not working correctly. |

a. AUX relay setting incorrect b. AUX relay wiring incorrect c. Inoperable expansion board or relay adapter board |

a. Check AUX relay switches settings b. Check that wiring is connected to either N.O. and COM or to N.C. and COM. c. Set AUX relay to another setting and test. Replace inoperable expansion board or relay adapter board. |

| Solar operator not getting enough cycles per day. |

a. Insufficient panel wattage b. Excessive accessory power draw c. Old batteries d. Solar panels are not getting enough sunlight |

a. Add more solar panels b. Reduce the accessory power draw by using LiftMaster low power accessories c. Replace batteries d. Relocate the solar panels away from obstructions (trees, buildings, etc.) |

| Solar operator, insufficient standby time. |

a. Insufficient panel wattage b. Excessive accessory power draw c. Battery capacity too low |

a. Add more solar panels b. Reduce the accessory power draw by using LiftMaster low power accessories c. Use batteries with higher amp hour (AH) rating |

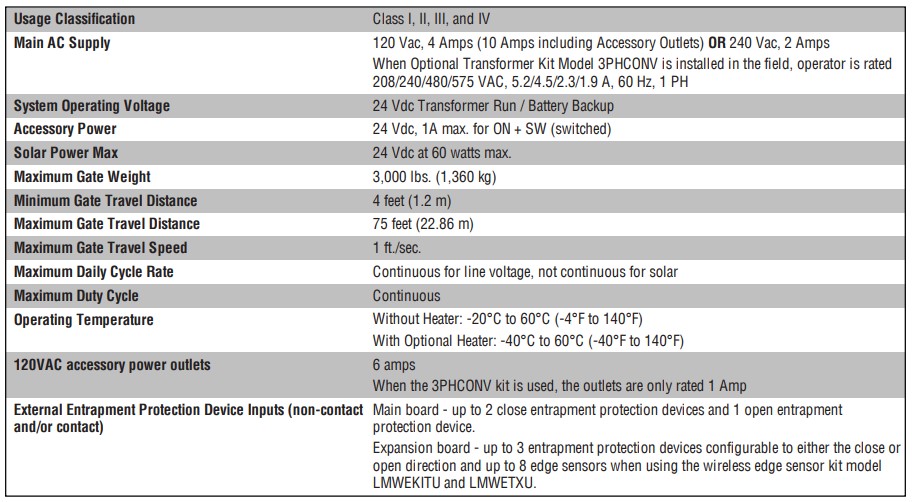

Operator Specifications

See other models: LA400UL PPLK1-10 PPLK1PH-10 LJ8950W J 5.0