Loading ...

Loading ...

Loading ...

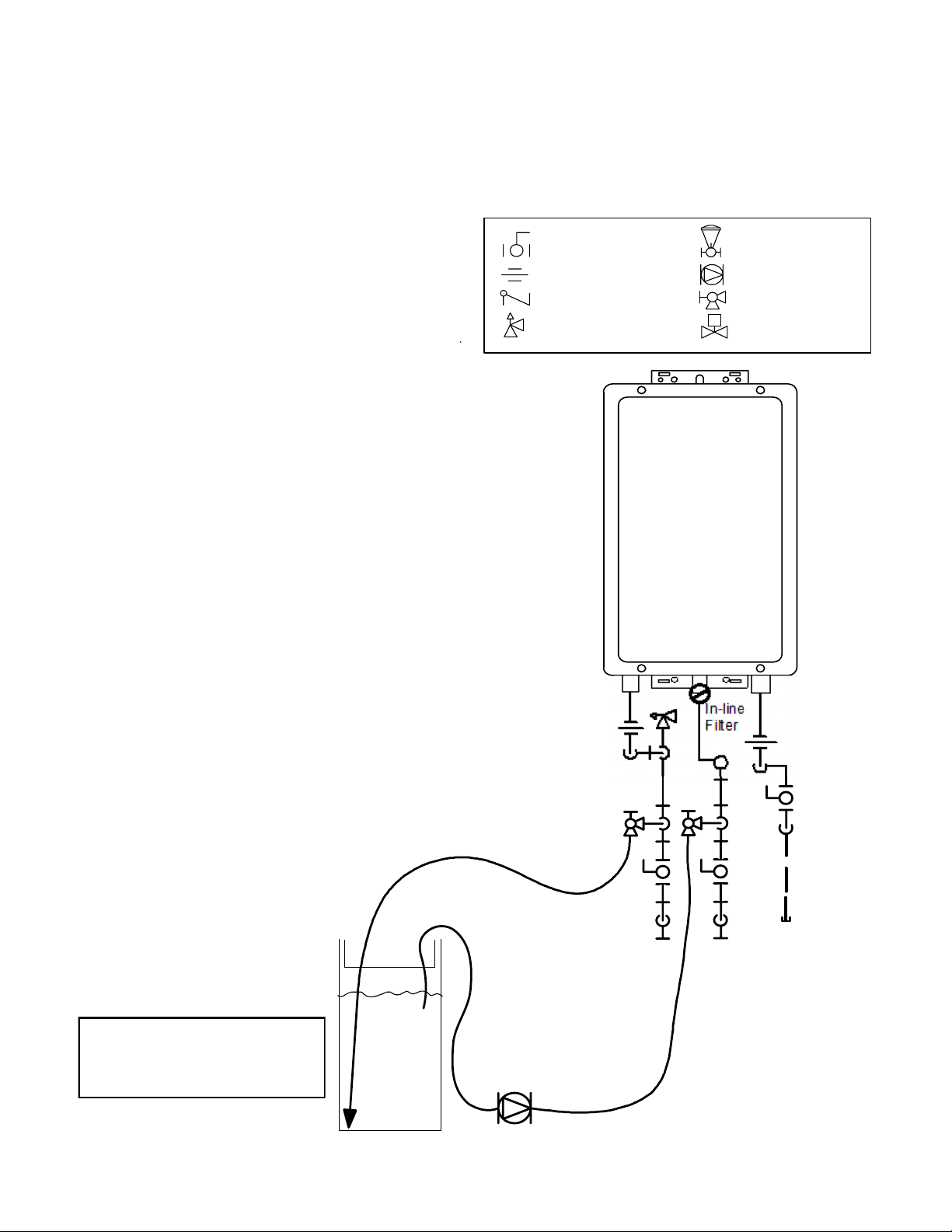

38 Value Series Manual

Water Heater

Pressure Relief Valve

3/4" Ball Valve

3/4" Union

Check Valve

S

Pressure Regulator

Circulating Pump

Solenoid Valve

Boiler Drain Valve

KEY

G

a

s

S

u

p

p

l

y

V1

V3

V2

V4

H1

H2

H3

Circulating Pump

C

o

l

d

W

a

t

e

r

L

i

n

e

H

o

t

W

a

t

e

r

L

i

n

e

n

-

l

i

n

e

F

i

l

t

e

r

I

Rinnai

An LC0~LC9 or “00” diagnosc code indicates the unit is beginning to lime up and must be ushed. Failure to

ush the appliance will cause damage to the heat exchanger. Damage caused by lime build-up is not covered by

the unit’s warranty. Rinnai strongly recommends installaon of isolaon valves to allow for ushing of the heat

exchanger.

1. Disconnect electrical power to the water heater.

2. Close the shuto valves on both the hot water and

cold water lines (V3 and V4).

3. Connect pump outlet hose (H1) to the cold water

line at service valve (V2).

4. Connect drain hose (H3) to service valve (V1).

5. Pour 4 gallons (15.1 liters) of undiluted virgin, food

grade, white vinegar into pail.

6. Place the drain hose (H3) and the hose (H2) to the

pump inlet into the cleaning soluon.

7. Open both service valves (V1 and V2) on the hot

water and cold water lines.

8. Operate the pump and allow the vinegar to circulate

through the water heater for at least 1 hour at a rate

of 4 gallons per minute (15.1 liters per minute).

9. Turn o the pump.

10. Rinse the vinegar from the water heater as follows:

a. Remove the free end of the drain hose (H3) from

the pail. Place in sink or outside to drain.

b. Close service valve, (V2), and open shuto valve,

(V4). Do not open shuto valve, (V3).

c. Allow water to ow through the water heater for

5 minutes.

d. Close shuto valve (V4). When unit has nished

draining remove the in-line lter at the cold water

inlet and clean out any residue. Place lter back

into unit and open valve (V4).

e. Close service valve, (V1), and open shuto valve,

(V3).

Flushing the Heat Exchanger

11. Disconnect all hoses.

12. Restore electrical power to the

water heater.

Following ush procedure call

technical assistance (1-800-621-

9419) for PCB reset informaon.

Loading ...

Loading ...

Loading ...