Loading ...

Loading ...

Loading ...

Servicing Your Honda 67

Valve Clearance

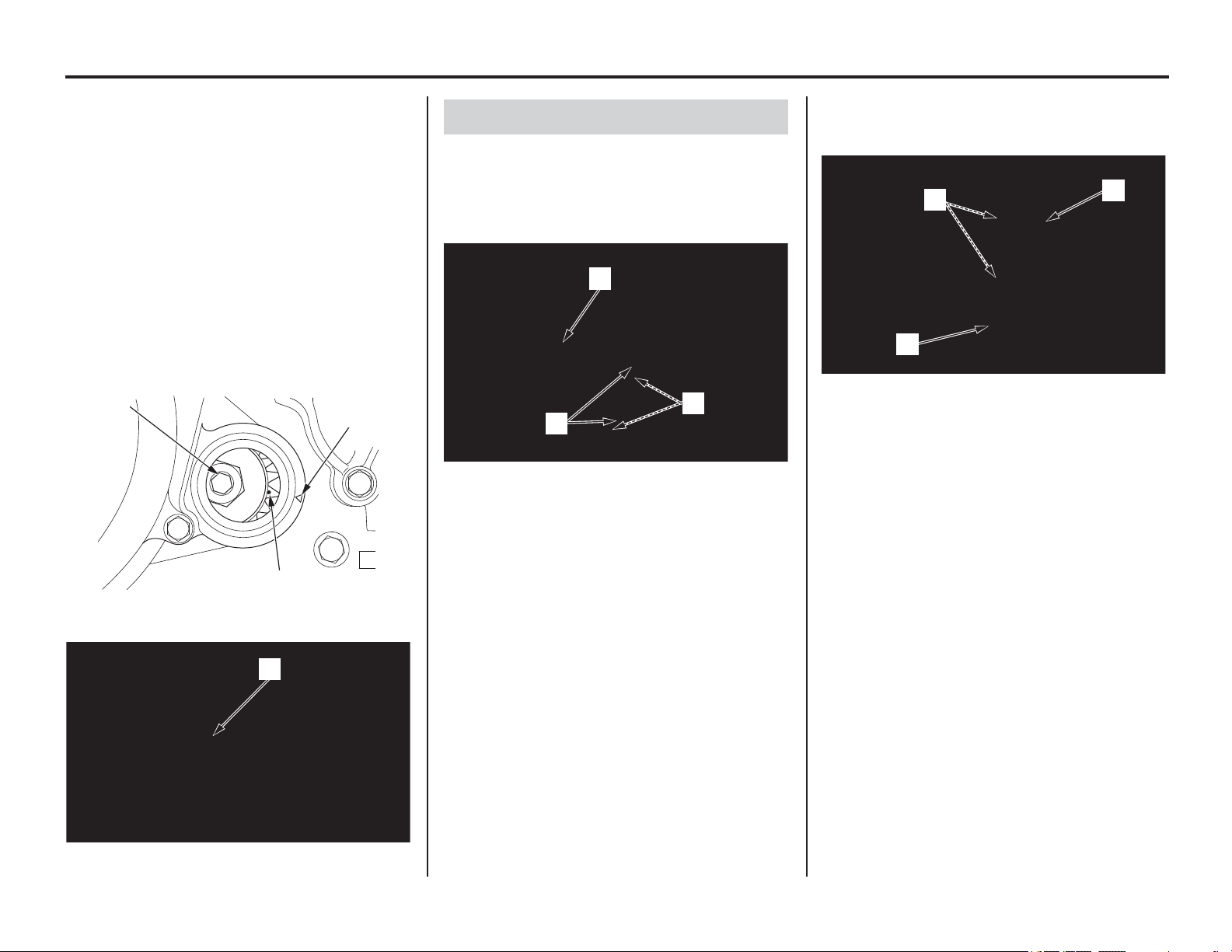

4. Rotate the crankshaft by turning the primary

drive gear bolt (2) clockwise until aligning the

punch mark (3) on the primary drive gear with

the “ǻ” mark (4) on the right crankcase cover.

In this position, the piston may either be on the

compression or exhaust stroke.

If the crankshaft passed the punch mark, rotate

the primary drive gear bolt clockwise again

and align the punch mark with the “ǻ” mark.

The inspection must be made when the piston

is at the top of the compression stroke when

both the intake and exhaust valves are closed.

This condition can be determined by moving

the exhaust rocker arm (5). If it is free, it is an

indication that the valves are closed and that

the piston is on the compression stroke. If it is

tight and the valves are open, rotate the

primary drive gear bolt 360° and realign the

punch mark to the “ǻ” mark.

1. Set the piston at TDC on the compression

stroke (page 66).

2. Measure the intake valve clearance by

inserting a feeler gauge (1) between the valve

lifters (2) and intake cam lobe (3).

3. Measure the exhaust valve clearance by

inserting a feeler gauge (1) between the

exhaust rocker arm (4) and shims (5).

Valve Clearances:

If intake valve clearance and exhaust valve

clearance need adjustment, see Camshaft Removal

(page 68) and select the correct shim for each

valve.

(2) primary drive gear bolt

(4) “

ǻ” mark

(3) punch mark

(5) exhaust rocker arm

(2)

(3)

(4)

(5)

Valve Clearance Inspection

(1) feeler gauge

(2) valve lifters

(3) intake cam lobe

(1)

(3)

(2)

(1) feeler gauge

(4) exhaust rocker arm

(5) exhaust valve shims

IN: 0.005 ± 0.001 in (0.12 ± 0.03 mm)

EX: 0.011 ± 0.001 in (0.28 ± 0.03 mm)

(5)

(1)

(4)

Loading ...

Loading ...

Loading ...