Loading ...

Loading ...

Loading ...

General Competition Maintenance

32 Servicing Your Honda

GREASE

GREASE

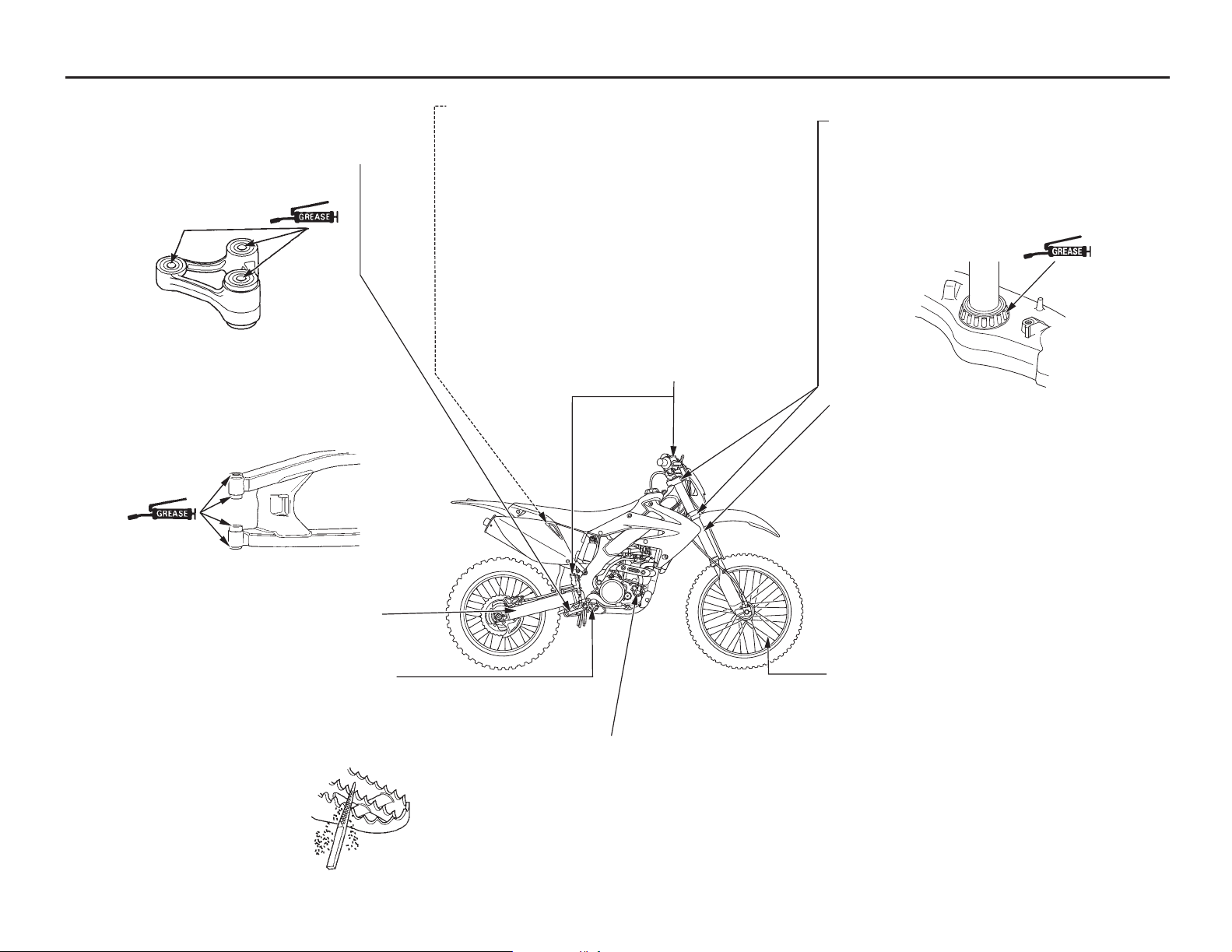

Suspension Linkage Lubrication

Disassemble, clean, inspect and lubricate all suspension linkage

pivot bearings with grease after each 7.5 hours of running time

in order to maintain proper suspension performance and

minimize component wear.

Swingarm Pivot Lubrication

Clean, inspect and lubricate the swingarm and suspension

linkage pivots with grease. Be sure all of the dust seals are in

good condition.

Swingarm

Do not attempt to weld or otherwise repair a damaged

swingarm. Welding will weaken the swingarm.

Footpegs

Worn footpeg teeth can be repaired by filing the grooves

between the teeth with a triangular-shaped file.

Be aware that filing them too sharp will reduce boot sole

lifespan. Sharpen only the points of the teeth. Filing the

grooves deeper will weaken the footpegs. Be sure the pegs

are free to pivot freely and that the pivot pin retaining cotter

pins are in good condition.

Fuse

Check the fuse before looking elsewhere for the cause of an

electrical problem.

Brake Fluid Replacement

Refer to Brake Pad Wear in your Owner’s Manual, page 89.

Brake Caliper Inspection: Be sure both the front and rear

calipers are able to move freely on the caliper bracket pins.

Check pad thickness periodically and replace the pads when

minimum thickness is reached. If the brakes fade when they are

hot, inspect the pads for glazing or damage, and replace if

necessary.

Brake Fluid Replacement: Replace the hydraulic fluid in the

brake system every 2 years. Replace the fluid more frequently

if you subject your brakes to severe use. Heavy braking heats

the brake fluid and it may deteriorate sooner than expected.

Any type of riding, that requires frequent use of the brakes,

such as in tight woods, can shorten the service life of brake

fluid.

Spokes

Check spoke tension frequently between the first few rides.

As the spokes, spoke nuts and rim contact points seat-in, the

spokes may need to be retightened. Once past this initial

seating-in period, the spokes should hold their tension. Still,

be sure your race maintenance program includes checking

spoke tension and overall wheel condition on a regular basis

(page 90).

Nuts, Bolts, Etc

Application of a thread locking agent to essential fasteners

offers added assurance and security. Remove the nuts, clean

the threads of both the nuts and bolts, apply Pro Honda

Hondalock or an equivalent and tighten to the specified torque.

Fork Oil/Performance

Disassemble, clean and inspect the fork and replace the oil

regularly. Contamination due to the tiny metal particles

produced from the normal action of the fork, as well as

normal oil breakdown, will deteriorate the performance of

the suspension. Refer to the Honda Service Manual

(page 168). Use only Pro Honda HP Fork Oil 5W (U.S.A.

only) or equivalent which contains special additives to

assure maximum performance of your CRF’s front

suspension.

Steering Head Bearings

Periodically clean, inspect and regrease the steering head

bearings — especially if wet, muddy or extremely dusty

courses are encountered often.

Use urea based multi-purpose grease designed for high

temperature, high pressure performance (example:

EXCELITE EP2 manufactured by KYODO YUSHI, Japan

or Shell Stamina EP2 or equivalent).

Frame

Because your CRF is a high-performance machine, the

frame should not be overlooked as part of your overall

competition maintenance program. Periodically inspect the

frame closely for possible cracking or other damage. It

makes good racing sense.

Bleed Hole

After every race, check the bleed hole, located just below the

water pump cover on the right crankcase cover. Clean away

any clogged dirt or sand, if necessary. Check for signs of seal

leakage. A small amount of “weeping” from the bleed hole is

normal.

Loading ...

Loading ...

Loading ...