Loading ...

Loading ...

Loading ...

Water Maze Compact CoAg • 9.801-506.0-D

9

WATER TREATMENT SYSTEM

DEALER MANUAL

The following instructions will provide adequate infor-

mation to fully install your Water Maze Treatment and

Recycling System. Please follow these instructions

step by step to ensure proper installation.

Equipment and Supplies

Needed for Installation

Aside from having a general assembly of tools on

hand, you will need to supply a few additional items

to complete the installation of your system.

• Forklift • Tape Measure

• Level • Hose Clamps

• Grey Flex Hose Pipe

#8.711-813.0 Sold by Ft.

INSTALLATION & OPERATING INSTRUCTIONS

INSTALLATION & START-UP INSTRUCTIONS

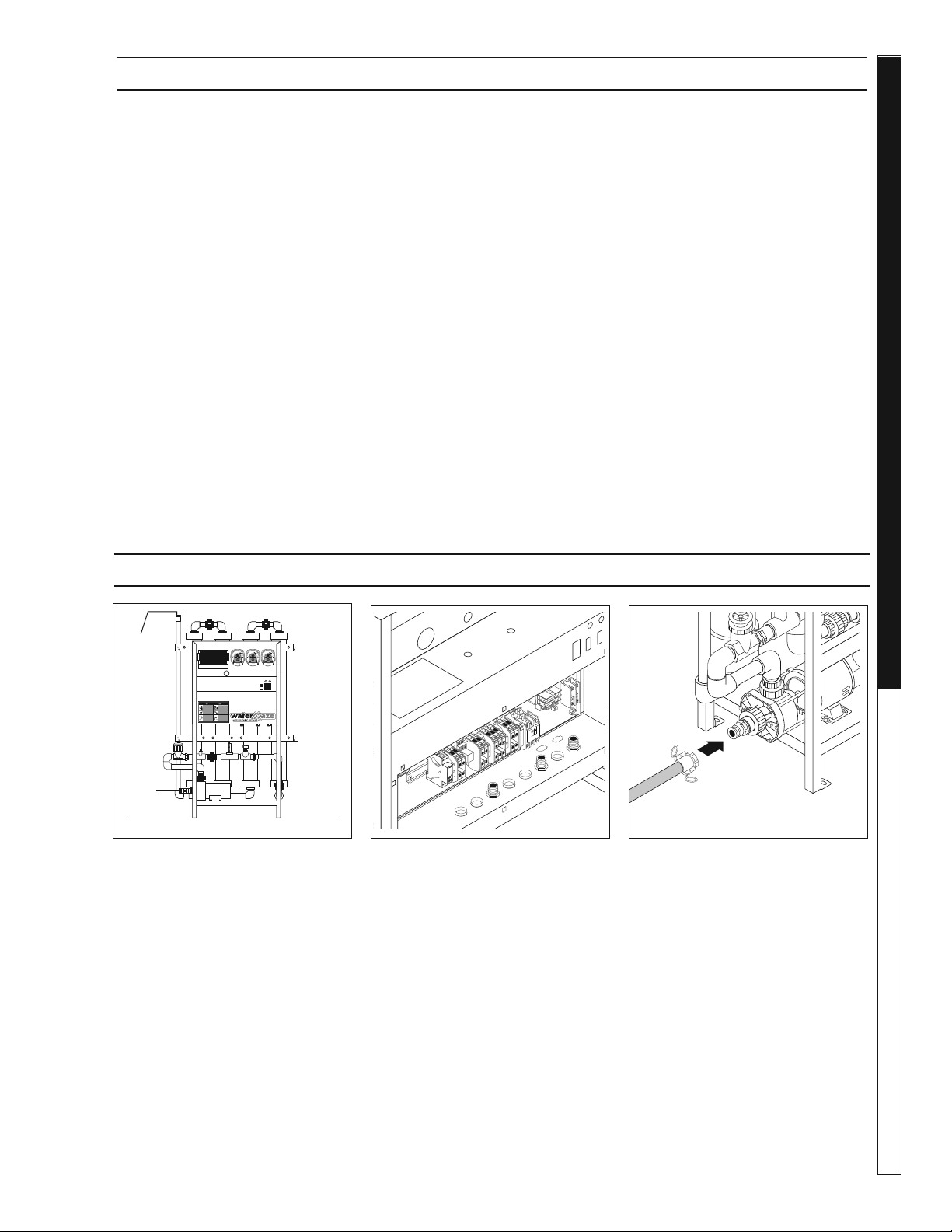

STEP 1: The Compact CoAg water

treatment system must be installed

on a level surface. If surface is not

level, shimming is required.

STEP 2: Connect the inlet piping

from either the above ground feed

tank to the optional infeed pump

installed on the chassis of the

Compact CoAg. Or, connect the

inlet piping from a sump pump to

the inlet manifold on the Compact

CoAg unit.

STEP 3: An electrician will con-

nect incoming electrical power

to the power block in the electri-

cal box. When connecting to the

power supply, follow all electrical

and safety codes as well as the

most recent National Electric Code

(NEC) and Occupational Safety

and Health Act (OSHA). Ground

system before connecting power

supply.

UTILITY USAGE

Water: 30-90 PSI

Electrical: 120 Volts, 1 PH, 20 Amps

98015060-8

RISK OF INJURY—

PROTECTIVE

EYEWEAR AND

CLOTHING MUST

BE WORN. when

operating this ma-

chine.

PROTEJASE LOS OJOS CU-

ANDO se opere este equipo.

DES LUNETTES DE SECURITE

DOIVENT ETRE PORTEES

lorsque vous operez cet appareil.

WARNING

PRECAUCION / AVERTISSEMENT

TO REDUCE THE

RISK OF INJURY

READ OPERATOR’S

MANUAL

CAREFULLY

BEFORE USING.

THIS MACHINE TO

BE USED ONLY BY

QUALIFIED

OPERATORS.

LEA EL MANUAL OPERACION AN-

TES DE USARSE. ESTE EQUIPO

DEBE SER USADO SOLAMENTE

POR OPERADORES CALIFICA-

DOS.

LIRE LE MANUEL DE

L’OPERATEUR AVANT UTILISA-

TION. CET APPAREIL DOIT ETRE

UTILISE PAR DES OPERATEURS

QUALIFIES.

RIESGO DE ELECTROCUCIÓN

— Conecte el enchufe en un con-

tacto adecuado. Mantenga todas

las connecciones secas y arriba del

suelo. No rocie componentes eléctri-

cos. Desconecte la corriente eléctrica

antes de dar servicio.

RISQUE D’ELECTROCUTION

— Relier à des prises avec mise à la

terre seulement. Tous les fils doivent

être maintenus secs et étre suspen-

dus. No jamais projeter de l’eau sur

les composantes et fils électriques.

Couper l’alimentatation électrique

avant de faire une réparation.

RISK OF

ELECTROCUTION.

Connect only to

properly grounded

outlet. Keep all con-

nections dry and off

the ground. Keep

spray away from

electrical wiring

and components.

Disconnect from

electrical supply

before servicing.

RISK OF

INJECTION OR

SEVERE INJURY

TO PERSONS.

Keep clear of

nozzle.

HOT DISCHARGE

FLUID .

Do not touch or

direct discharge

stream at persons.

RIESGO DE PENETRACIÓN O

LESIONES SEVERAS A PERSO-

NAS. Manténgase fuera del alcance

de boquilla.

DESCARGA DE AGUA CALIENTE

A ALTA PRESION — No toque ni

dirija el flujo del agua a otras perso-

nas.

RISQUE DE BLESSURES. Se tenir

loin des buses.

EAU CHAUDE SOUS PRESSION A

LA SORTIE — Ne pas diriger le jet

d’eau vers des personnes.

SPRAY GUN

KICKS BACK.

Hold with both

hands.

LA PISTOLA SE MUEVE CON LA

PRESIÓN — Sostenga con las dos

manos.

LA POIGNEE PISTOLET RE-

POUSSE — Tenir à deux mains.

RISK OF INJURY—

HOT SURFACES

CAN CAUSE BURNS.

Use only designed

gripping areas of

spray gun and wand.

SUPERFICIES CALIENTES

— Use solamente las áreas

aisladas del gatillo y la lanza.

SURFACES CHAUDES

— Toucher seulement les parties

isolées des poignée pistolets et

lances.

8.940-047.0

LOW

LIQUID

PUMP

ON

STOP

POWER

RUN

9.807-597.0

98015060-13

98015060-9

STEP 4: Assemble a fl ex hose

with cam-lock fi ttings and connect

from your waste water source to

the waste water inlet connection

on the left side of the machine.

Outlet

Inlet

General Notations: Compact Coag System

1. Inlet from pretreatment pit system to tank:

a. Flooded suction is most desirable.

When drawing water up from a pit, a foot

valve (check valve) may be required.

b. Cam lock (male and female) supplied with

system.

2. Typical pretreatment considerations may include:

a. Settling of heavy solids

b. Removal of free fl oating oils

c. pH adjustment

3. Outlet Indexing Paper Filter or another

dewatering device:

a. Cam lock (male and female) supplied with

system

b. Hose (1.5 inch diameter) is not included.

Loading ...

Loading ...

Loading ...