Loading ...

Loading ...

Loading ...

Water Maze Compact CoAg • 9.801-506.0-D

DEALER MANUAL WATER TREATMENT SYSTEM

16

DANGER: DO NOT AT TEMPT TO USE CHEM-

I CALS WITH OUT CON SULT ING YOUR CHEM I CAL

DEAL ER OR CHEM I CAL SUP PLI ER. READ MSDS

BEFORE HANDLING.

CAUTION: Wear pro tec tive

gloves, gog gles, and oth er

adequate pro tec tion for the

chem i cal haz ard.

Before re plac ing the pump head,

remove chemical from tub ing as

follows:

1. Remove strain er from chem i-

cal tank.

2. Run pump un til all chem i cal is re moved from the

tub ing.

FILL THE CHEMICAL TANK: To avoid run ning out,

of chemical, fol low a regular sched ule of mon i tor ing

chem i cal supply. Also inspect and clean the strain er

by fl ushing with a compatible liq uid, as need ed.

INSPECT SQUEEZE TUBING: Inspect tub ing regu-

larly and re place it if it is deteriorating.

REPLACE SQUEEZE TUB ING:

1. Remove compression fi ttings from the tubing at

the pump head.

2. Pull the suction and dis charge tub ing from the

pump head.

3. Remove the front cover from the pump.

4. Rotate the pump rollers to a vertical position.

5. Lift the inlet fi tting out of the housing.

6. Pull the tube out while rotating the pump rollers

clockwise.

7. Remove the outlet fi tting.

8. Install the inlet fi tting for the new tube assembly.

9. Press the tube into place in front of a roller while

rotating the roller assembly clockwise.

10. Install the outlet fi ttings.

11. Reconnect the suction and discharge lines.

12. Install the front cover.

CAUTION: DO NOT LOSE THE BEAR ING FROM

THE CEN TER HOLE IN THE BACK COVER.

TUBE REPLACEMENT:

Clear or transparent plas tic tubing should be re placed

at least every three months if ex posed to the sun.

Replace tubing yearly if feeder is in stalled indoors.

INSPECT FOR LEAKAGE:

Inspect the chemical system daily for any signs of leak-

age. If leaking occurs at tubing connections, tighten fi t-

ting compression nut fi nger tight. If leakage con tin ues,

re move pressure from the system. Disconnect the

tub ing, trim ends square and reconnect.

INSPECT FOR BLOCKED FLOW:

Precipitates or other chemical reactions cause in-

jec tion points to clog. If the type of chemical being fed

elim i nates the use of fl ushing solution, the injection

point must be in spect ed at regular intervals. Strainers

must be kept clean with periodic back-fl ush ing.

WARNING

PROTECTIVE

EYEWEAR AND

CLOTH ING MUST

BE WORN.

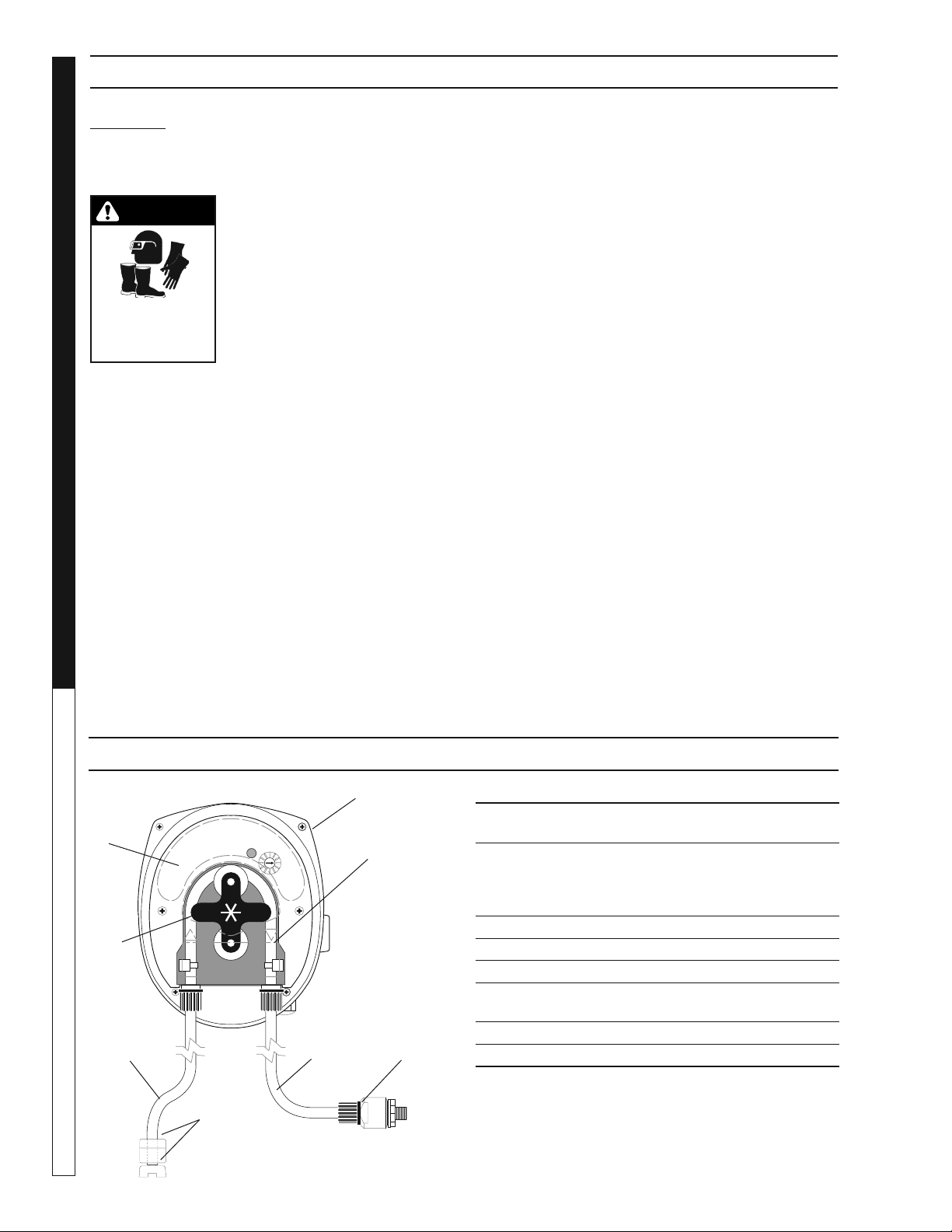

ITEM PART NO. DESCRIPTION QTY

1 8.749-856.0 Pump, Peristaltic, PRS-1,

1-7 gpd 2

2 8.749-862.0 Tube, Squeeze, Santoprene,

*

PR-7, 8-45 gpd 1

8.749-864.0 Tube, Squeeze, Santoprene,

*

PRS-1, 1-7 gpd 1

3 8.749-860.0 Check Valve, PVC 1

4 8.749-857.0 Tubing, 1/4", PE, Black AR

5 8.749-863.0 Strainer, w/Weight 1

6 8.711-737.0 Tubing, 1/8" , ID,

Norprene AR

7 8.751-801.0 Faceplate, PRS-1/PR-7 1

8 8.751-376.0 Roller Assembly, PRS-1 1

* Alternative tubing materials are available

1

2

3

6

4

7

8

5

METERING PUMP AND PARTS LIST

METERING PUMP MAINTENANCE

Loading ...

Loading ...

Loading ...