Loading ...

Loading ...

Loading ...

Water Maze Compact CoAg • 9.801-506.0-D

DEALER MANUAL WATER TREATMENT SYSTEM

6

Compact CoAg Water Treatment Unit:

The Compact CoAg water treatment unit can be

installed as a recycle or a treat & discharge water

system. The Compact CoAg may also be installed as

a component of a system that incorporates multiple

water treatment technologies. In certain applications

the constituents in the water may require additional

pre-treatment or post treatment of the fl uid stream.

To assure the best processed water quality, pretreat-

ment of the waste water should be applied to address

the following waste water characteristics:

• Heavy solids: Excessive amounts of heavy sol-

ids (especially solids that quickly fall out) should

be removed prior to entering the Compact CoAg

system.

• Free-oils (oils that are fl oating on the surface of

the water): Although the Compact CoAg will typi-

cally address both free-oils and emulsifi ed oils,

excessive amounts of free-oils should be removed

prior to entering the system.

• pH of the water: Typically, the Compact CoAg

system performs best when the pH of the infl uent

waste water is between 7 and 8. If the pH is out-

side these limits, pH adjustment will be necessary.

Consult Water Maze for recommendation.

• Post-treatment: Subject to the application re-

quirements, additional water treatment may be

required.

Consult a Water Maze representative prior to com-

bining the Compact CoAg with other pre-treating

and post treating equipment.

TCLP Testing:

TCLP is one of the Federal EPA test methods that

are used to characterize waste as either hazardous

or non-hazardous for the purpose of disposal. TCLP

is an acronym for Toxicity Characteristic Leaching

Procedure. A TCLP test may be required prior to

disposal of your solid waste. Consult a Water Maze

representative for details.

Site Preparation:

The installation site surface should be of compacted

materials, such as concrete, asphalt or pavement and

capable of supporting the Compact CoAg treatment

system.

APPLICATION AND INTENDED USE

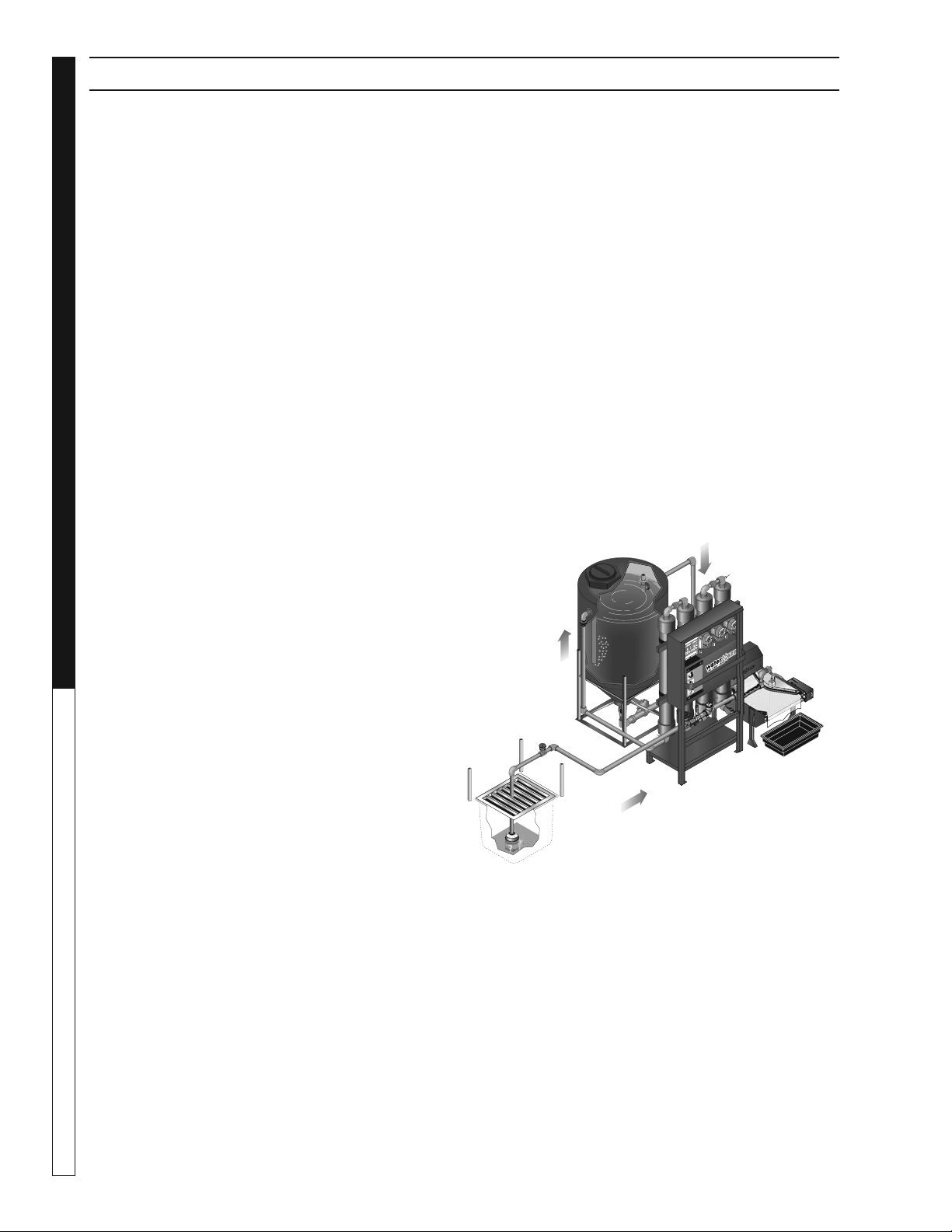

Typical Applications

This section outlines some of the common confi gura-

tions for the Compact CoAg module.

As a treatment & discharge system:

1. Compact CoAg unit receives pretreated water and

applies pH control (if required); applies chemical

coagulant and chemical fl occulent.

2. A small cone-bottom reactor tank is positioned

immediately after the Compact CoAg unit, which

allows for mixing of the chemical fl occulent and

provides additional processing dwell time.

a. This is the most (highly) recommended confi gu-

ration. (See special note* below).

b. Maximum estimated fl ow rate = up to 20 gpm

3. An IPF2-20D Indexing Polishing Filter (standard

unit, or High-boy unit), along with a lower water

retention container is positioned after the above

reactor tank. The IPF2-20D unit provides for sepa-

ration and dewatering of the gathered (fl occulated)

matter.

SPECIAL NOTE* – Confi guring the 150-gallon tank (as

shown), or another size of cone-bottom tank.

This tank receives the CoAg+ coagulated water (CoAg+

chemical injected in the 1st mixing tube) immediately

after the EC+ fl occulent is injected in the 4th mixing

tube. Please take note of the pipe on the inside of the

tank. It must be positioned near where the sloped-

bottom begins and it should have an elbow (45 or 90

degree) at the bottom that releases the water on an

oblique angle, which effectively allows the water to swirl

and to complete the mixing of the EC+ coagulant. Also

note the vertically oriented PVC Tee on the opposite

W

ARNING

P

R

E

C

A

U

T

I

O

N

/

ATTE

N

T

IO

N

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

WARNING

PRECAUTION/ATTENTION

WASTE WATER

INLET

SUMP PUMP / PIT

TO IPF

UNIT

COMPACT

CoAg UNIT

IPF UNIT

FROM

CoAg UNIT

98015060-19

The above shows a typical (most common) confi guration for

treatment & discharge (to sewer) applications.

Loading ...

Loading ...

Loading ...