Loading ...

Loading ...

Loading ...

31-5000573 Rev. 2 27

ENGLISH

INSTALLATION INSTRUCTIONS

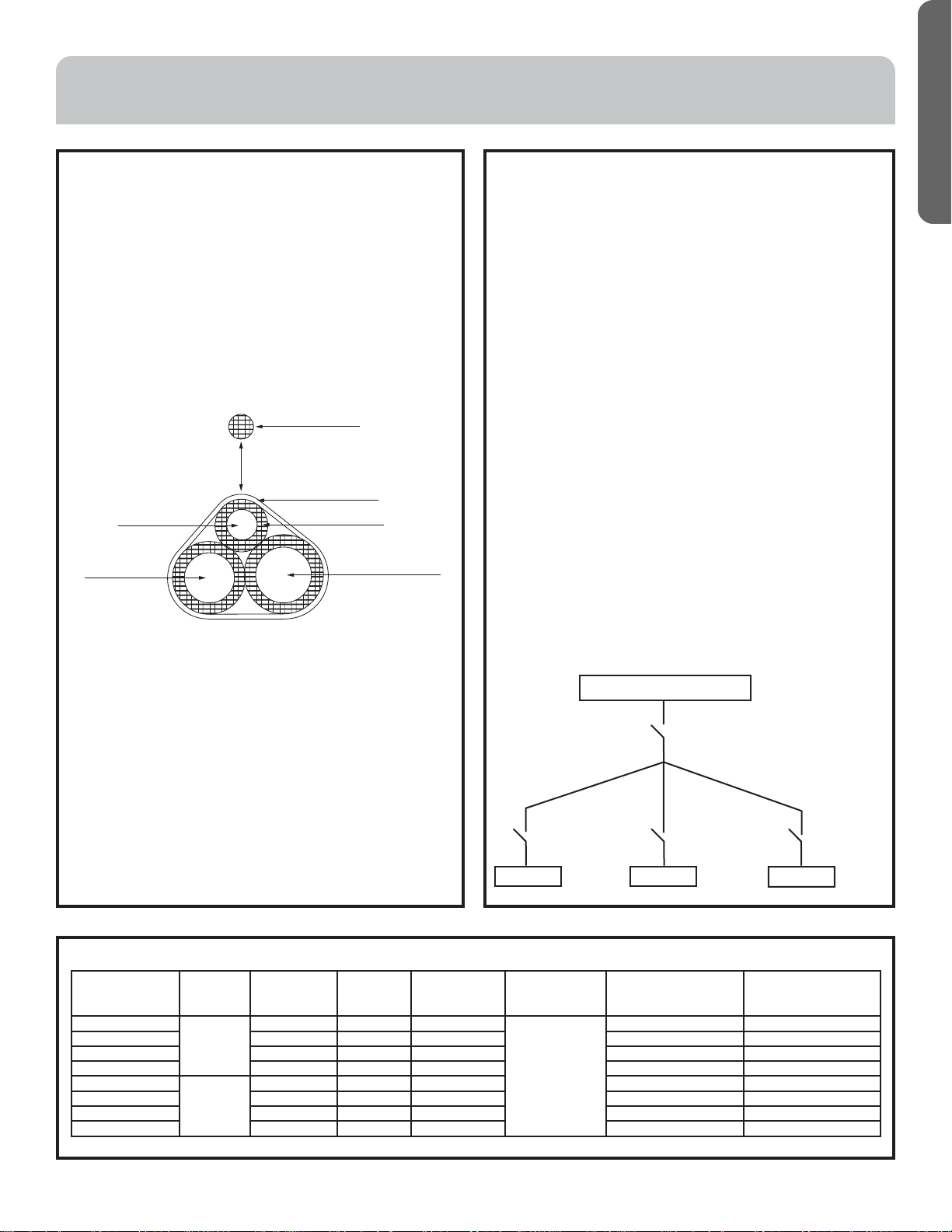

Insulation

• HP gas pipe, suction gas pipe, and liquid pipe should be heat

insulated separately.

• The insulation material for the hot gas and suction lines

should withstand a temperature of 248°F (120°C). The liquid

line insulation should be able to withstand temperatures over

158°F (70°C).

• The material thickness should be over 1/2in.(10mm), when

ambient temp. is 86°F (30°C), and the relative humidity is over

80%, the material thickness should be over 3/4in.(20mm).

• The material should fit over the pipe closely without gap, then

be wrapped with adhesive tape. The communication wire

should not run together with the insulation material and should

be spaced at least 8 inches.

Secure the refrigerant pipe.

• The refrigerant lines will expand and contract during operation

so it is important that they be supported properly.

• Support lines every 7 to 10 ft.

• Check leakage on the pipe connections when installation is

finished.

• When checking leakage of refrigerant or reinstalling the

system, make sure to turn the compressor off and then

disconnect the pipe.

• Do not operate the compressor in condition of unconnected

pipe, refrigerant leakage and incorrectly connected pipe. If not

it may cause air to flow into compressor and lead an explosion

or malfunction.

• If there's any possibility of small animals entering the pipe

from outlet, then block it.

Electric Wiring and Applications (Cont.)

Electric Wiring and Applications

1. Please follow all national and local electric codes. All

wiing materials should comply with local and national

codes. All work should be done by professional

electricians.

2. Power supply must be provided at the rating plate level.

Fluctuations in the power supply must be less than 2%

phase to phase. Outdoor and indoor units must have

their own dedicated power supply.

3. Electrical connections from disconnects to equipment

should be properly secured.

4. Power conductors should be sized in accordance with

national and local codes. Equipment must be properly

grounded to earth through the circuit breaker panel.

5. Equipment electrical circuits must be protected by the

properly sized breaker per codes.

6. Do not add filter capacitors to the power supply

servicing this equipment.

7. Follow these installation instructions when wiring the

equipment to avoid injury or accidents.

8. The unit must be reliably grounded to meet the national

requirements.

9. All electrical installations must be carried out by

professionals in accordanve with local laws, regulations,

and corresponding instructions.

Power Control Cabinet

Outdoor 1 Outdoor 2

Circuit breaker

Circuit breaker

Circuit breaker

Circuit breaker

Outdoor 3

Suction Gas Pipe

Heat Insulator

Adhesive Tape

Over 8in. (200mm)

Liquid Pipe

HP Gas Pipe

Connection Wire

Model

Power

Source

Maximum load

current (A)

Circuit

breaker (A)

Each model

circuit breaker

(A)

Leakage current

(mA) response

time (S)

Minimum sectional

area of power line AWG

(mm

2

)

Minimum sectional

area of earthing line

AWG (mm

2

)

MVHR072ME2CA

208/230V~

60Hz 3PH

30 40 40

30mA, below

0.1s

7(10) 7(10)

MVHR096ME2CA 38 50 50 7(10) 7(10)

MVHR120ME2CA 41 60 60 7(10) 7(10)

MVHR144ME2CA 56 80 80 3(25) 5(16)

MVHR072ME4CA

460V~

60Hz 3PH

16 20 20 9(6) 9(6)

MVHR096ME4CA 20 25 25 9(6) 9(6)

MVHR120ME4CA 22 30 30 9(6) 9(6)

MVHR144ME4CA 30 40 40 7(10) 7(10)

Loading ...

Loading ...

Loading ...